Chuck in WA

Member

Hi All,

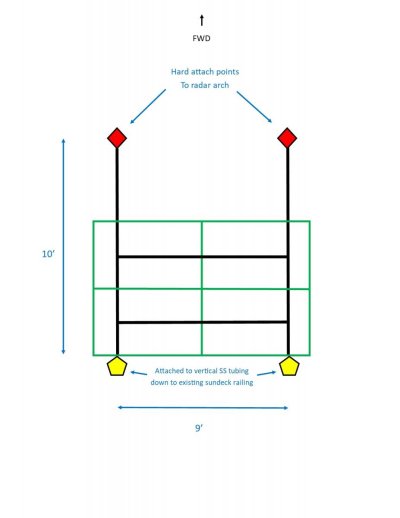

I'm attempting to design a support structure for 4 solar panels, fabricated from 1" SS tubing (Bimini/handrail stuff, .065 thickness). My boat is a "sundeck" style, and my plan for the structure is to attach the fwd tubing to the radar arch, then run the tubing aft to the end of the sundeck, where it will 90* down and attach to the existing railing. When the panels are installed, it will almost create a "hardtop" of sorts above the sundeck. My concern is the length of span (around 10'), which will be otherwise unsupported, so I wanted to solicit your thoughts about this aspect. The total weight of the panels will be under 200 pounds. Attached is a "God's eye view" drawing of my proposed construction (not to scale).

I've had 6" of wet/heavy PNW snow on my bimini (of similar dimensions) before with no adverse effects, but the bimini is supported differently and the bows are slightly curved (the solar mount will be flat), so perhaps apples to oranges.

In the picture, black lines=SS tubing and green lines=solar panel position.

One thing to note regarding my attached image before comments begin - it does not show any aft lateral support I will build in, simply to keep the picture a little cleaner.

TIA for your thoughts!

I'm attempting to design a support structure for 4 solar panels, fabricated from 1" SS tubing (Bimini/handrail stuff, .065 thickness). My boat is a "sundeck" style, and my plan for the structure is to attach the fwd tubing to the radar arch, then run the tubing aft to the end of the sundeck, where it will 90* down and attach to the existing railing. When the panels are installed, it will almost create a "hardtop" of sorts above the sundeck. My concern is the length of span (around 10'), which will be otherwise unsupported, so I wanted to solicit your thoughts about this aspect. The total weight of the panels will be under 200 pounds. Attached is a "God's eye view" drawing of my proposed construction (not to scale).

I've had 6" of wet/heavy PNW snow on my bimini (of similar dimensions) before with no adverse effects, but the bimini is supported differently and the bows are slightly curved (the solar mount will be flat), so perhaps apples to oranges.

In the picture, black lines=SS tubing and green lines=solar panel position.

One thing to note regarding my attached image before comments begin - it does not show any aft lateral support I will build in, simply to keep the picture a little cleaner.

TIA for your thoughts!

Another Forum member, hopefully we’ll hear from him, didn’t add any cross members and ended using straps as a temporary fix. As Mike pointed out, the lateral movement was pretty severe before he added the straps which worked but weren’t a permanent solution.

Another Forum member, hopefully we’ll hear from him, didn’t add any cross members and ended using straps as a temporary fix. As Mike pointed out, the lateral movement was pretty severe before he added the straps which worked but weren’t a permanent solution.