wkearney99

Guru

- Joined

- Feb 17, 2018

- Messages

- 2,189

- Location

- USA

- Vessel Name

- Solstice

- Vessel Make

- Grand Banks 47 Eastbay FB

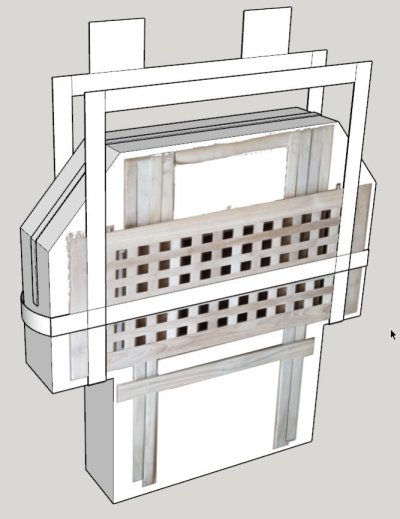

I've got a pair of nice teak folding tables. They work great. But when folded the sides tend to swing a bit when moving them for storage in the engine compartment. I'm going to have some bags made for them. But I'm unsure how to best design the bag.

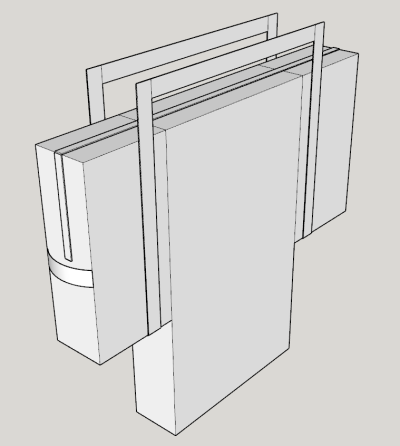

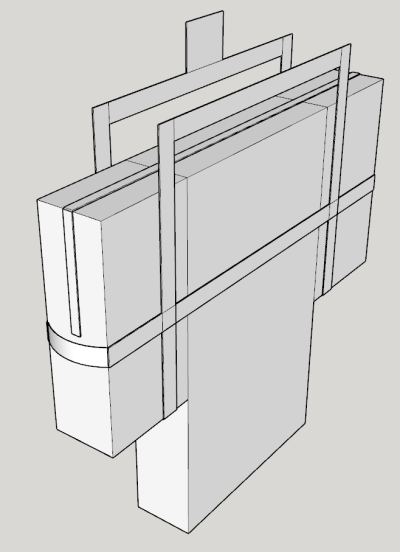

My plan is to make the bag like an inverted T shape, so it'll conform to the width of the bottom legs. This to avoid a lot of extra corner material to get caught on things. I plan on having some sort of pocket/sleeve/liner to help buffer the legs from smacking various fiberglass bits when lugging them up/down the engine room stairs.

I also plan on enclosing the bag fully, not leaving the wood 'carry handle' part exposed. This to avoid any engine room dirt from making a mess of them.

I'm thinking a duffel bag-like design, where the webbing would go under the table leaves, just outside the legs. And have a zipper running up from the half-way point down the side of leaves.

Anyone done something similar or have better design ideas?

My plan is to make the bag like an inverted T shape, so it'll conform to the width of the bottom legs. This to avoid a lot of extra corner material to get caught on things. I plan on having some sort of pocket/sleeve/liner to help buffer the legs from smacking various fiberglass bits when lugging them up/down the engine room stairs.

I also plan on enclosing the bag fully, not leaving the wood 'carry handle' part exposed. This to avoid any engine room dirt from making a mess of them.

I'm thinking a duffel bag-like design, where the webbing would go under the table leaves, just outside the legs. And have a zipper running up from the half-way point down the side of leaves.

Anyone done something similar or have better design ideas?