I’ve had each of the three variants at one time or another, and as you might expect, there are trade offs with each.

In all cases I have also had a main engine driven hydraulic pump. They are great for running stabilizers, but you typically end up under powered for thrusters. It can be weak for a windlass too, especially if combined with an anchor wash. As alluded to earlier, this is because all these things are done when the engine is at idle. There are limits to how much power you can pull off an engine at idle (10% is a good starting point), and you are limited in the size of the pump that will fit which limits max flow. With twin mains it’s more plausible to size things to work. You can also kick up the engine idle speed a bit to 800-900 rpm, but no more without compromising the transmission. This all leads to an aux source of power, plus of course the desire for backup propulsion.

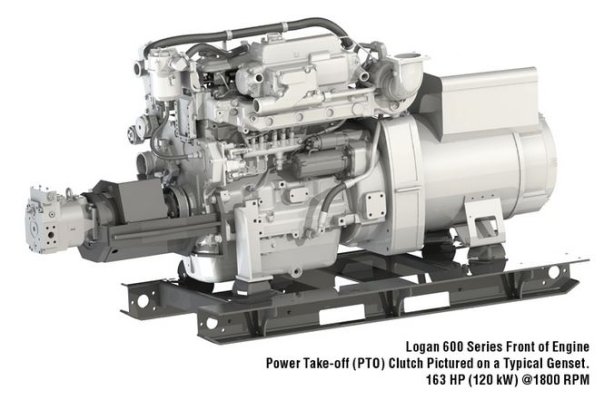

A clutched PTO pump off a generator can do a lot. You have the generator, so it’s a relatively straight forward add. The down side is that it can be under powered. The boat I had configured like this also had a main engine pump with elevated idle, and at times it was still underpowered. This is why it’s so common to pump such a pump on a wing engine instead. It’s also important to know that when using the generator to drive the hydraulic pump, you cannot put any electric loads on it. I stalled by generator every time when I forgot to turn off the breaker for the generator loads. The boats I know where this works have two generators with pumps that they run together.

The other question that came up is around using generator power to drive a get-home drive of some sort. The biggest issue again is the limited power available, and even more so in this case. One thing working for you is that hydraulic get home drives almost always drive the main shaft. That’s much more efficient that an off center folding prop. But even turning the main shaft, boats I know like this are typically limited to 4 kts or so in flat water.

Then come the variants on this like using electric motors to drive thrusters and get home drives, or using an electric motor to drive a hydraulic pump. All can work, but all have the same power constraints, give or take a bit.

The fundamental issue is that you generally need a much smaller generator for house power use, a good bit bigger for thrusters, and a good bit bigger again for get-home. My current boat I think illustrates this well. The relative sizes are what matter, with the absolute numbers scaling with boat size.

The generator is 25kw and serves the house loads well. That’s about a 40hp engine to drive it.

The thrusters are 35 hp each, so 70hp together. That’s about double what the generator can deliver.

Get home tops out at 160hp at about 5.5 kts. That’s more than double again what the thrusters need.

I considered a larger generator to combine the generator and wing/aux engines into one, but to get equivalent performance I would have needed a 120 kw generator plus a lot more complicated hydraulic or electric controls. Or I would have forfeited performance and/or features.

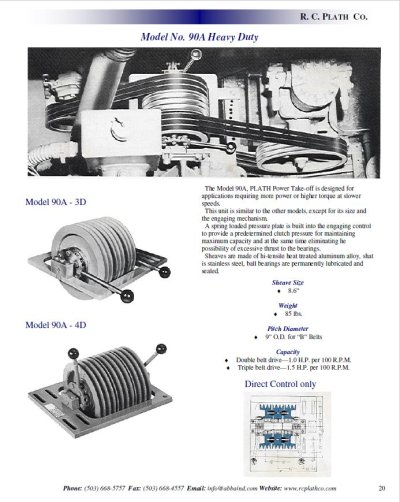

I do currently have an electrically driven hydraulic pump, principally for stabilization at rest. This was recommended over a PTO driven pump because apparently the clutches are designed to cycle rather than remain engaged for extended time, and there have been consequential lubrication and bearing failures. Electric drive on the pump solves that, but the motor is huge and so is the VFD that drives it.