O C Diver

Guru

- Joined

- Dec 16, 2010

- Messages

- 13,312

- Location

- Fort Myers, Florida

- Vessel Name

- End Of The Line

- Vessel Make

- Trinka 10 Dinghy

If your holding tank looks like the upper part of this one

and you want it to look like this one

I have the answer.

So, my holding tank was so fouled on the inside, that I couldn't see the liquid level. What started out as a process to just be able to see the level became an obsession to get it completely clean. I read all the postings from the Head Mistress, added to her recommendation, and had an undesirable outcome (not the Head Mistress's fault). So let me explain what did and didn't work for me.

I have an 80 gallon holding tank. Generally, due to the size, 2 gallons of degreaser laundry detergent is recommend. I used 2 gallons of Purex the first time which was a mistake on my part. The second time less than a gallon of Tide (the preferred brand) was used.

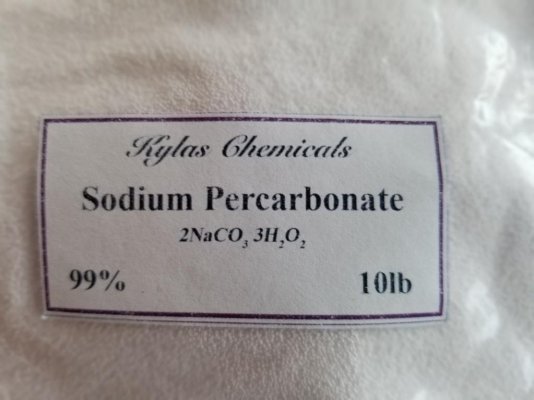

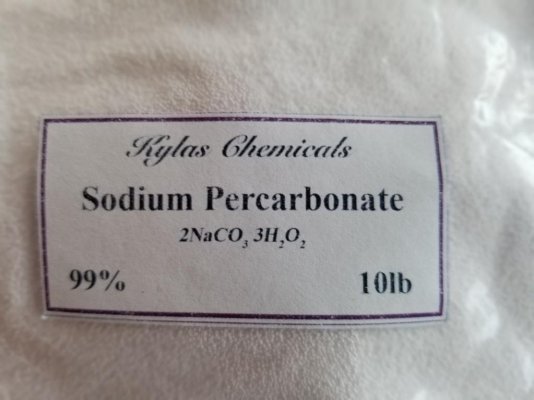

Each time I used Sodium Percarbonate, 10 pounds the first time and about 8 pounds the second time. For those not familiar with Sodium Percarbonate, it's the main ingredient in Oxyclean. In a thread on the forum it was also suggested as the main ingredient in one of the popular head plumbing cleaning granular additives (not going to say any more than that). My thought was that this would dramatically improve the cleaning action of the laundry soap. 10 pounds is around $20 on ebay. This was not recommended by the Head Mistress.

To the soap and Sodium Percarbonate you add water and agitate the tank. This is where my first attempt about a year ago went really badly. I flushed the tank out well with fresh water. Then with 150 degree hot water (we all know hot water can accelerate chemical reactions), I poured the 10 pounds of Sodium Percarbonate into the pumpout port for my holding tank (basically a slurry). Next was the 2 gallons of Purex. Finally, I emptied the remainder of my 20 gallon hot water tank into the holding tank and put the cap back on the pumpout port. The plan was to go outside the harbor, roll in the troughs of 2' seas to agitate the concoction until the water heater was ready to add another 20 gallons of water to the holding tank. About a half hour later when the water was hot, I removed the cap for the pumpout port and was greeted with a brown foamy outflow. I won't bore you with the remediation and cleanup processes. Lets just say I returned to the pumpout dock unobserved, emptied the tank and cleaned up the boat.

I won't bore you with the remediation and cleanup processes. Lets just say I returned to the pumpout dock unobserved, emptied the tank and cleaned up the boat.

Incident analysis (it's only an accident if you get caught) determined that the Sodium Percarbonate doesn't dissolve instantly (especially when sitting in a pile in the bottom of the holding tank. Too much of the wrong kind of soap without enough water makes an incredible amount of foam. Hot water really enhances chemical reactions. Apparently rolling a boat is a great way to dissolve the Sodium Percarbonate and trigger one hell of a chemical reaction. The final insult was that the chemical reaction worked, freed some solids, which floated on the foam, eventually plugging the holding tank vent.

You might think after this experience that I would concede defeat and leave well enough alone. Time heals all wounds and egos.

Time heals all wounds and egos.

Version 2.0

This time I decided to approach the task in a more restrained manner. I procured another 10 pounds of Sodium Percabonate, a 1.2 gallon jug of Tide and dialed the water temperature back to 100 degrees. This time I mixed batches of cleaning solution. In a 6 gallon bucket I dissolved about 6 ounces (by volume) of Sodium Percabonate in 4 gallons of hot water. It took a couple of minutes of stirring with my hand before there were no granules left on the bottom. Then I added about 5 ounces of Tide which mixed instantly. After waiting several minutes on the first batch to check for adverse reactions, I filled the bowl of my Vacuflush toilet and flushed it. It actually took 2 rounds to flush the 4 gallons into the system. I rinsed the bowl with a little fresh water and repeated the process on the second toilet. After waiting 2 days, I flushed about 10 gallons of fresh water through each toilet, and went to the pumpout dock to empty the holding tank and rinse it.

This picture was taken after cleaning and rinsing the holding tank.

Much of the 8 gallon concoction went right into the holding tank and cleaned it in 2 days.

Armed with this new found knowledge, I went back to my slip and made numerous 4 gallon batches that I pored into the pumpout deck port. About every 4 batches I would check the holding tank for Thermal Nuclear Reactions. I decided to keep the liquid level about an inch below the vent based on previous experience.

This is what the tank looked like before I started:

This is what it looked like 2 hours after filling the tank. Clearly the concoction is dissolving the stuff on the walls.

This is what it looked like 2 days later:

And this is what it looked like after pumping it out:

Conclusion:

Clearly the Tide and Sodium Percarbonate dissolved the residue without any agitation required. Could I use less of each, possibly. Mixing it up in batches was clearly a safer approach. Some of the residue on the walls settled to the bottom while some floated to the top of the liquid. Staying below the tank vent and flushing the vent line afterwards is important!

I liked the idea of cleaning and flushing the toilet plumbing and feel confident that neither of the chemicals will attack the rubber parts based on dilution and duration. Will be heading to the boatyard in a week or so and will probably go through one vacuum pump to check the duck bill valves.

Ted

and you want it to look like this one

I have the answer.

So, my holding tank was so fouled on the inside, that I couldn't see the liquid level. What started out as a process to just be able to see the level became an obsession to get it completely clean. I read all the postings from the Head Mistress, added to her recommendation, and had an undesirable outcome (not the Head Mistress's fault). So let me explain what did and didn't work for me.

I have an 80 gallon holding tank. Generally, due to the size, 2 gallons of degreaser laundry detergent is recommend. I used 2 gallons of Purex the first time which was a mistake on my part. The second time less than a gallon of Tide (the preferred brand) was used.

Each time I used Sodium Percarbonate, 10 pounds the first time and about 8 pounds the second time. For those not familiar with Sodium Percarbonate, it's the main ingredient in Oxyclean. In a thread on the forum it was also suggested as the main ingredient in one of the popular head plumbing cleaning granular additives (not going to say any more than that). My thought was that this would dramatically improve the cleaning action of the laundry soap. 10 pounds is around $20 on ebay. This was not recommended by the Head Mistress.

To the soap and Sodium Percarbonate you add water and agitate the tank. This is where my first attempt about a year ago went really badly. I flushed the tank out well with fresh water. Then with 150 degree hot water (we all know hot water can accelerate chemical reactions), I poured the 10 pounds of Sodium Percarbonate into the pumpout port for my holding tank (basically a slurry). Next was the 2 gallons of Purex. Finally, I emptied the remainder of my 20 gallon hot water tank into the holding tank and put the cap back on the pumpout port. The plan was to go outside the harbor, roll in the troughs of 2' seas to agitate the concoction until the water heater was ready to add another 20 gallons of water to the holding tank. About a half hour later when the water was hot, I removed the cap for the pumpout port and was greeted with a brown foamy outflow.

Incident analysis (it's only an accident if you get caught) determined that the Sodium Percarbonate doesn't dissolve instantly (especially when sitting in a pile in the bottom of the holding tank. Too much of the wrong kind of soap without enough water makes an incredible amount of foam. Hot water really enhances chemical reactions. Apparently rolling a boat is a great way to dissolve the Sodium Percarbonate and trigger one hell of a chemical reaction. The final insult was that the chemical reaction worked, freed some solids, which floated on the foam, eventually plugging the holding tank vent.

You might think after this experience that I would concede defeat and leave well enough alone.

Time heals all wounds and egos.

Time heals all wounds and egos.Version 2.0

This time I decided to approach the task in a more restrained manner. I procured another 10 pounds of Sodium Percabonate, a 1.2 gallon jug of Tide and dialed the water temperature back to 100 degrees. This time I mixed batches of cleaning solution. In a 6 gallon bucket I dissolved about 6 ounces (by volume) of Sodium Percabonate in 4 gallons of hot water. It took a couple of minutes of stirring with my hand before there were no granules left on the bottom. Then I added about 5 ounces of Tide which mixed instantly. After waiting several minutes on the first batch to check for adverse reactions, I filled the bowl of my Vacuflush toilet and flushed it. It actually took 2 rounds to flush the 4 gallons into the system. I rinsed the bowl with a little fresh water and repeated the process on the second toilet. After waiting 2 days, I flushed about 10 gallons of fresh water through each toilet, and went to the pumpout dock to empty the holding tank and rinse it.

This picture was taken after cleaning and rinsing the holding tank.

Much of the 8 gallon concoction went right into the holding tank and cleaned it in 2 days.

Armed with this new found knowledge, I went back to my slip and made numerous 4 gallon batches that I pored into the pumpout deck port. About every 4 batches I would check the holding tank for Thermal Nuclear Reactions. I decided to keep the liquid level about an inch below the vent based on previous experience.

This is what the tank looked like before I started:

This is what it looked like 2 hours after filling the tank. Clearly the concoction is dissolving the stuff on the walls.

This is what it looked like 2 days later:

And this is what it looked like after pumping it out:

Conclusion:

Clearly the Tide and Sodium Percarbonate dissolved the residue without any agitation required. Could I use less of each, possibly. Mixing it up in batches was clearly a safer approach. Some of the residue on the walls settled to the bottom while some floated to the top of the liquid. Staying below the tank vent and flushing the vent line afterwards is important!

I liked the idea of cleaning and flushing the toilet plumbing and feel confident that neither of the chemicals will attack the rubber parts based on dilution and duration. Will be heading to the boatyard in a week or so and will probably go through one vacuum pump to check the duck bill valves.

Ted

Last edited: