Rand900

Newbie

- Joined

- Nov 26, 2021

- Messages

- 1

- Vessel Name

- Winsome

- Vessel Make

- Sparkman Stephens ketch

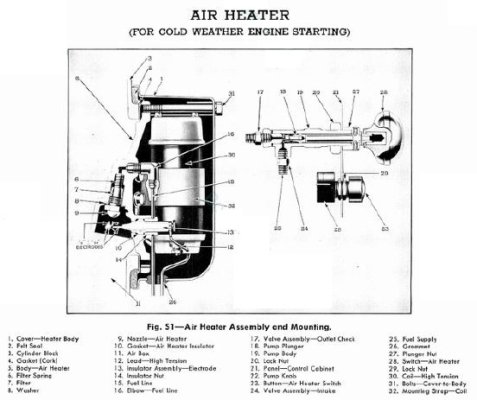

I have a 1955 detroit diesel 471 runs fine it just doesn't want to start ( you have to crank it for quite some time, or use starting fluid ).

It has H80 injectors, I have tried putting a fuel line to the secondary fuel filter with an electric pump to be sure there is fuel to the injectors.

The injectors only have a few hours since a rebuild.

Thank you

Randall

It has H80 injectors, I have tried putting a fuel line to the secondary fuel filter with an electric pump to be sure there is fuel to the injectors.

The injectors only have a few hours since a rebuild.

Thank you

Randall