- Joined

- Nov 8, 2012

- Messages

- 2,323

- Location

- Port Orchard, WA

- Vessel Name

- Sandpiper

- Vessel Make

- Bluewater 40 Pilothouse Trawler

I finally pulled the trigger on an ultrasonic antifouling system.

I've been a dealer for Sonihull by NRG Marine - PYI is the US distributor and Ultra-SonicTec. I was unable to sell a single unit of either system because of buyer skepticism and no testimonials from PNW boaters.

The Sonihull uses two transducers and costs $2,250.

The Ultra SonicTec uses four transducers and retails for $2,500.

The two transducers in the Sonihull has higher output than the Ultra SonicTec and are good for boats up to about 50 - 55 feet.

I've been talking to both companies for about 4 years and never got any definitive report of results.

At the Pacific Marine Expo held last week in Seattle, PYI who distributes the Sonihull in the US out of Lynnwood, WA made me an offer I could not refuse. The offered me a discount better than the usual and Phil Quartararo from PYI guaranteed that the system will keep my bottom clean or he will give me a 100% refund.

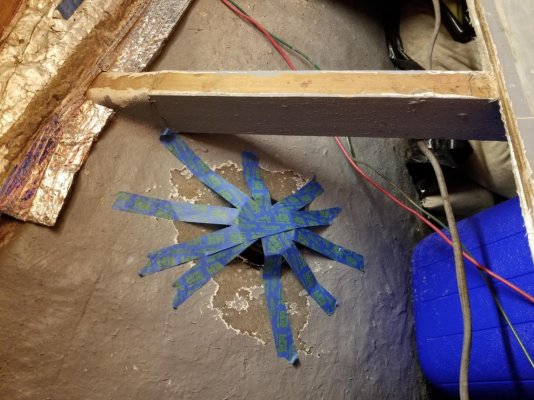

So I bought the two transducer Sonihull Duo and will be installing it on Sandpiper, a 40 foot, 13' beam, FRP, single engined displacement trawler next week.

I will monitor the results and post pictures.

Sandpiper does not get barnacles but gets covered in green slime and grass constantly. Even while cruising. I'm hoping the Sonihull will keep the slime from attaching to the bottom.

Wish me luck!

For more information on Sonihull - pyiinc.com

For Ultra-sonicTec - ultra-sonitec.com/

I've been a dealer for Sonihull by NRG Marine - PYI is the US distributor and Ultra-SonicTec. I was unable to sell a single unit of either system because of buyer skepticism and no testimonials from PNW boaters.

The Sonihull uses two transducers and costs $2,250.

The Ultra SonicTec uses four transducers and retails for $2,500.

The two transducers in the Sonihull has higher output than the Ultra SonicTec and are good for boats up to about 50 - 55 feet.

I've been talking to both companies for about 4 years and never got any definitive report of results.

At the Pacific Marine Expo held last week in Seattle, PYI who distributes the Sonihull in the US out of Lynnwood, WA made me an offer I could not refuse. The offered me a discount better than the usual and Phil Quartararo from PYI guaranteed that the system will keep my bottom clean or he will give me a 100% refund.

So I bought the two transducer Sonihull Duo and will be installing it on Sandpiper, a 40 foot, 13' beam, FRP, single engined displacement trawler next week.

I will monitor the results and post pictures.

Sandpiper does not get barnacles but gets covered in green slime and grass constantly. Even while cruising. I'm hoping the Sonihull will keep the slime from attaching to the bottom.

Wish me luck!

For more information on Sonihull - pyiinc.com

For Ultra-sonicTec - ultra-sonitec.com/