You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

New electrical panel

- Thread starter sndog

- Start date

The friendliest place on the web for anyone who enjoys boating.

If you have answers, please help by responding to the unanswered posts.

If you have answers, please help by responding to the unanswered posts.

Delta Riverat

Guru

- Joined

- Feb 16, 2022

- Messages

- 1,220

- Location

- Stockton

- Vessel Name

- Dream Catcher

- Vessel Make

- 1979 Island Gypsy 44 Flush Aft Deck

Most impressive. Looks like a server rack!

Thank you. I have one of those.being built out as well currently.Most impressive. Looks like a server rack!

Attachments

Thank youYou've done a great job!!

Capt Ray

Senior Member

Impressive.

2 thoughts:

1) There was a wire "label maker" discussed recently in one of the forums.

All your efforts equate to money-in-the-bank when it comes to sell that boat in 5-20 years!

2) DC (-) = Yellow

Best wishes on a great finish to your very great start...

2 thoughts:

1) There was a wire "label maker" discussed recently in one of the forums.

All your efforts equate to money-in-the-bank when it comes to sell that boat in 5-20 years!

2) DC (-) = Yellow

Best wishes on a great finish to your very great start...

Patrick4002

Senior Member

- Joined

- Nov 30, 2019

- Messages

- 134

- Location

- België

- Vessel Name

- Lady Penelope

- Vessel Make

- Trader 54 sunliner

nice panel, i have always room short in my cable trays

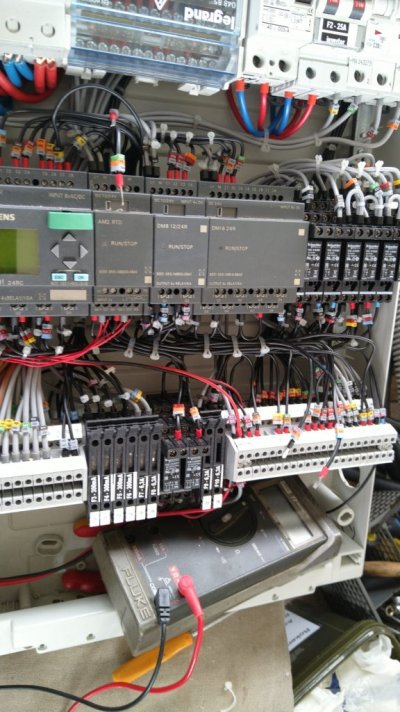

here is my latest on, testing all connections before building in the boat.

here is my latest on, testing all connections before building in the boat.

Attachments

Last edited:

twistedtree

Guru

That looks great. Perhaps you could post over here about how you are using that Siemens PLC? PLCs In Boatsnice panel, i have always room short in my cable trays

here is my latest on, testing all connections before building in the boat.

Patrick4002

Senior Member

- Joined

- Nov 30, 2019

- Messages

- 134

- Location

- België

- Vessel Name

- Lady Penelope

- Vessel Make

- Trader 54 sunliner

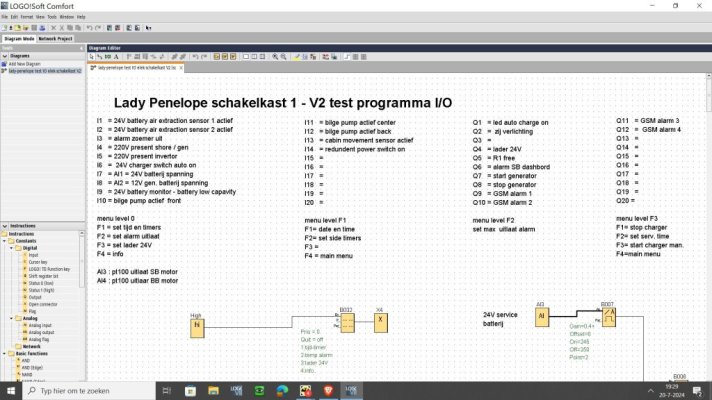

ok, i put a extended explanation in the plcs in boat.

just now a smalle explanation.

I was a process developer in the chemical industrie and we found that plc are very stable even for hard temp/vibration, ect. situations

I use the siemens logo system first its not so costly, you can use it for a lot, and i have the programmable software (i program them for the last 14 years)

On my boat hey have the following functions :

1. monitoring the motor exhaust tube temperature

2. monitoring the service bat capacity and (if selected) start/stop the generator.

3. control the bilg pumps and if they run to long phone me with a warning, if they run at critical time keep phoning till some anser or connect to the port security.

4. control timing for the side gang lights.

5. give a warning for refill check of the service battery (all on screen)

6. give a warning or phone if the 220v service get off line (for the coolers)

just making it safe and better control when not on board.

just now a smalle explanation.

I was a process developer in the chemical industrie and we found that plc are very stable even for hard temp/vibration, ect. situations

I use the siemens logo system first its not so costly, you can use it for a lot, and i have the programmable software (i program them for the last 14 years)

On my boat hey have the following functions :

1. monitoring the motor exhaust tube temperature

2. monitoring the service bat capacity and (if selected) start/stop the generator.

3. control the bilg pumps and if they run to long phone me with a warning, if they run at critical time keep phoning till some anser or connect to the port security.

4. control timing for the side gang lights.

5. give a warning for refill check of the service battery (all on screen)

6. give a warning or phone if the 220v service get off line (for the coolers)

just making it safe and better control when not on board.

Attachments

Thnk you. I have an epson 900 label maker and dymo xtl500 label maker. I use them to make labels up to I think 1.5" wide, as well as heat shrink labels for the wires. Both are very nice, but the cartridges are expensive. DC- for yellow is a great idea.Impressive.

2 thoughts:

1) There was a wire "label maker" discussed recently in one of the forums.

All your efforts equate to money-in-the-bank when it comes to sell that boat in 5-20 years!

2) DC (-) = Yellow

Best wishes on a great finish to your very great start...

This looks very nice and professional as well. My power transfer switches are off to the side of mine so you can walk right into the engine room and they are in your face. I am using automatic transfer switches though. I believe I have 8 of them.nice panel, i have always room short in my cable trays

here is my latest on, testing all connections before building in the boat.

Interesting forum to read through.That looks great. Perhaps you could post over here about how you are using that Siemens PLC? PLCs In Boats

Similar threads

- Replies

- 0

- Views

- 349

- Replies

- 16

- Views

- 641

Latest posts

-

-

-

-

48-volt house bank. Next Gen for boats?

- Latest: codingparadox

-

-

-

-

-

Victron Orion XS 12/12-50 DC2DC Charger ERROR

- Latest: Delta Riverat