Arthurc

Guru

Hi,

Took our first trip out after almost a year and was surprised to be woken up 6 hours after shutting down the gen to a low battery alarm and a voltage of 11.4v. Batteries were in float before i shut down and i was drawing about 60a per my Maretron as my heating system was on. Would love some advice on best next steps. Even at a 60a draw I should have got at least 12 hours before I hit 60 percent which is what i try not to go under. Unfortunately I didn’t realize I had the mute switch flipped on my alarm so I don’t know when it went below 50.

Details:

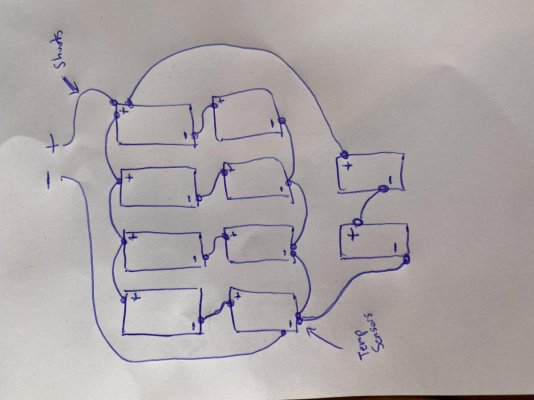

1800ah of Lifeline L16s at 12v

Xantrex 3012 inverter/charger set to AGM profile and correct bank size.

Balmar MC-614 (200a alternator, single engine)

Questions:

-Could something have happened while on shore power that damaged the batteries or could the charge controller have been tricked into under charging? About 2 years ago while in a yard someone did knock the shore power cable loose causing the batteries to drop to 10v or below, that said lifeline didn’t seem too concerned by that as it was noticed quickly. Also last summer I had the 3012 set to 5a as I was on a private dock with only 15a 110, but without much use I can’t see how that would have harmed things since float uses way less than that.

-Any initial tests I should run?

-Is it worth equalizing the batteries? I know most agms that’s not recommended but lifeline seems to say it’s ok.

-Could the few times I run both the gen and main engine at the same time cause an issue or long term damage?

Any other suggestions or advice would be appreciated! I’d like to avoid a major retrofit of my batteries/charging as with supply shortages I’d worry I won’t get it done before our bigger trip north. Not to mention I have other boat projects I’d rather spend the money on.

Thanks much!

Arthur

Took our first trip out after almost a year and was surprised to be woken up 6 hours after shutting down the gen to a low battery alarm and a voltage of 11.4v. Batteries were in float before i shut down and i was drawing about 60a per my Maretron as my heating system was on. Would love some advice on best next steps. Even at a 60a draw I should have got at least 12 hours before I hit 60 percent which is what i try not to go under. Unfortunately I didn’t realize I had the mute switch flipped on my alarm so I don’t know when it went below 50.

Details:

1800ah of Lifeline L16s at 12v

Xantrex 3012 inverter/charger set to AGM profile and correct bank size.

Balmar MC-614 (200a alternator, single engine)

Questions:

-Could something have happened while on shore power that damaged the batteries or could the charge controller have been tricked into under charging? About 2 years ago while in a yard someone did knock the shore power cable loose causing the batteries to drop to 10v or below, that said lifeline didn’t seem too concerned by that as it was noticed quickly. Also last summer I had the 3012 set to 5a as I was on a private dock with only 15a 110, but without much use I can’t see how that would have harmed things since float uses way less than that.

-Any initial tests I should run?

-Is it worth equalizing the batteries? I know most agms that’s not recommended but lifeline seems to say it’s ok.

-Could the few times I run both the gen and main engine at the same time cause an issue or long term damage?

Any other suggestions or advice would be appreciated! I’d like to avoid a major retrofit of my batteries/charging as with supply shortages I’d worry I won’t get it done before our bigger trip north. Not to mention I have other boat projects I’d rather spend the money on.

Thanks much!

Arthur