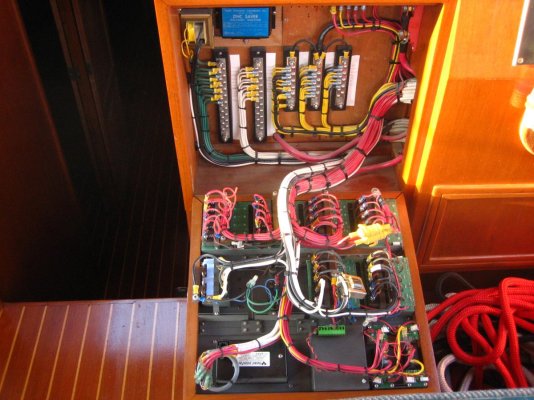

As part of my refit (Willard 36), I am having the boat totally rewired. Every old wire removed. Like many boats, Weebles suffered from many DIY installs, many by myself.

Custom panel with back plane was about $3200. Electrician $9600 and includes install of new solar, electronics and lighting (Mexico, but not dirt cheap - mechanics and electricians are still $50-$60 per hour). Engine was out of boat, old ER sound insulation removed and new raceways installed along with new sound down ER insulation. I did the electrical design work which took at least 100 hours by the time it was done and parts ordered.

Done properly, it's at least a $15k job, probably closer to $20k. In my opinion, there are very few DIY owners who can do it right. There are quite a few who could do an okay job, but if you want straight, well supported and tagged wiring runs and a beautiful display when you open the panel, its beyond the patience of all but meticulous DIY owners.

Finally, as mentioned, I probably have 100 hours into planning alone including working with the panel builder to design the new panel. Thinking through all the wiring is very tedious in itself. Wire gauge, where to place switches, new bus bar for new, lower energy electronics, solenoids, inverters, and a lot more that didn't exist in 1970 when my boat was first launched. Without a detailed plan, probability of satisfactory results are greatly diminished.

Rewiring has without a doubt been the most complicated project during my refit. And will have the lowest return on investment to my heirs when I'm dead and gone and someone has to sell her. I did it because I've spent 20 years looking at my FUBAR wiring. I don't want to spend another hour of my life ever seeing it again.

Boats cause rational people to make irrational decisions. Rewiring a boat is Exhibit 1.

Peter