STB

Guru

Hi all,

I bought my current boat about 1.5 years ago at the tail end of a major overhaul and have been getting the details worked out ever since (totally expected).

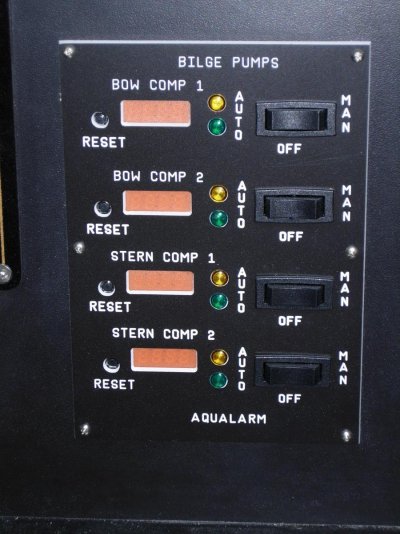

A couple of weekends ago I reinstalled what were once, and now are again, "high" and "super high" bilge water level alarms on the flybridge, which are in addition to the ones on the lower level.

Then, last weekend, I came back in from a short trip out and, upon washing up, I heard a noise and thought I'd left the shower sump pump on. Nope. It was the lowest bilge pump barely keeping up (but keeping up).

No alarms were going off -- the alarms are set just above the lowest pump's level. And, the counter wasn't counting -- the pump started a "cycle" and was still on that cycle pumping away.

Things could have gone badly if I left the boat and the bilge pumps clogged or the boat lost power and they ran the batteries out, or they otherwise failed. By the time the boat filled up a bit and the alarms went off -- I'd have been long, long gone and the batteries could be too dead for the alarm, anyway.

I might tie the "super high" alarm to the horn via a relay or transistor, interrupted by a NC relay when the ignition circuit is on. That way, if I'm not running the boat, and something like this happens -- the boat persistently yells out in an attention-getting way to the neighbors and marina for help.

But, in any case, the leak made me think -- I really need a "now pumping" light at each helm -- as well as a 12V chronometer/totalizer for that lowest pump to tell me that it has been running, and for how long it has been running, since the last time I reset the counter.

Something similar to one of these is the idea:

-- https://www.ebay.com/itm/Red-LED-Di...r-industrial-12V-DC-Meter-Panel-/251248898156

-- https://www.amazon.com/DIGITEN-Digital-Totalizer-Chronometer-Industrial/dp/B00VKASYPC

Any 12V Hobbes gauge would actually work -- but for the ability to easily reset (from the front).

For the models above, the basic idea would be to use the device to time how long the bilge pump has run since the last reset, installing one such device at each helm:

-- The same float switch that powers the pump is used as the timed (IN)put to the chronographs.

-- GND is, well, the (-)GND

-- RST is connected via a normally open momentary switch to ground.

-- And nominal +12VDC (8VDC-12VDC) power is connected BOTH via a diode (0.7VDC volt drop) to the (IN)put and via another diode to the ignition-powered instrument circuit.

The idea being that when the boat is in use, the gauge will be ignition powered and show the total number of hours:minutes:seconds the bilge pump has run since the last reset. When the boat is not in use, the gauge will be unpowered and dark, unless the float switch powers it along side the pump, in which case the pump circuit will power the pump, power the gauge, and serve as input to the chronometer to be counted. Since the chrony remembers the cumulative time, even when unpowered, the display will in fact be cumulative.

About the only catch is I don't know how these chronometers react when they hit 99:99:99. I'd like for them to stop there or show an overflow code -- but they might wrap around to 0 which could hide a problem after 4+ days of cumulative pump operation.

I obviously need fuses, but don't need to worry about the 0.7V drop across the diodes, as the nominal 12VDC input and power are good down to 8VDC. (Alternatively, I could also use a relay or transistor to let the pump and ignition circuit switch an always-on power circuit -- but that seems more complicated than need be).

So....my questions are these....

-- Why are cycle counters more common than run time counters, e.g. chornograph totalizers?

-- Why do people prefer counters to something like this? They seem more common?

-- Am I missing something? This seems like it is clearly the right way to go.

If you happen to be curious about that dripless shaft seal (DSS)....it isn't as big of a problem or surprise as it may seem.

When I bought the boat, the surveyor told me the boot, carbon stator, stainless rotor, clamps, etc, were all good. And, they all seemed good to me. But, although the boot felt soft and good, it didn't push the carbon very hard against the rotor. It just seemed to have gotten comfortable squished. So, it was on my radar.

I called the PO and the PPO and neither remembered ever replacing the boots, etc. And, together they went back almost two decades. When I had the boat hauled to do a thru-hull (I was out of town) they checked the boots and told me they were fine. So, I figured I do them in a year or so along with the bottom paint.

Well, that was a year ago. I still don't need bottom paint. But, may get it anyway while replacing the boots.

For now, I slid the boot and the rotor closer together to get more compression and pressure to seal and that solved the problem. I also ordered the maintenance kits. And, am working on scheduling the haul.

Many thanks!

-Greg

I bought my current boat about 1.5 years ago at the tail end of a major overhaul and have been getting the details worked out ever since (totally expected).

A couple of weekends ago I reinstalled what were once, and now are again, "high" and "super high" bilge water level alarms on the flybridge, which are in addition to the ones on the lower level.

Then, last weekend, I came back in from a short trip out and, upon washing up, I heard a noise and thought I'd left the shower sump pump on. Nope. It was the lowest bilge pump barely keeping up (but keeping up).

No alarms were going off -- the alarms are set just above the lowest pump's level. And, the counter wasn't counting -- the pump started a "cycle" and was still on that cycle pumping away.

Things could have gone badly if I left the boat and the bilge pumps clogged or the boat lost power and they ran the batteries out, or they otherwise failed. By the time the boat filled up a bit and the alarms went off -- I'd have been long, long gone and the batteries could be too dead for the alarm, anyway.

I might tie the "super high" alarm to the horn via a relay or transistor, interrupted by a NC relay when the ignition circuit is on. That way, if I'm not running the boat, and something like this happens -- the boat persistently yells out in an attention-getting way to the neighbors and marina for help.

But, in any case, the leak made me think -- I really need a "now pumping" light at each helm -- as well as a 12V chronometer/totalizer for that lowest pump to tell me that it has been running, and for how long it has been running, since the last time I reset the counter.

Something similar to one of these is the idea:

-- https://www.ebay.com/itm/Red-LED-Di...r-industrial-12V-DC-Meter-Panel-/251248898156

-- https://www.amazon.com/DIGITEN-Digital-Totalizer-Chronometer-Industrial/dp/B00VKASYPC

Any 12V Hobbes gauge would actually work -- but for the ability to easily reset (from the front).

For the models above, the basic idea would be to use the device to time how long the bilge pump has run since the last reset, installing one such device at each helm:

-- The same float switch that powers the pump is used as the timed (IN)put to the chronographs.

-- GND is, well, the (-)GND

-- RST is connected via a normally open momentary switch to ground.

-- And nominal +12VDC (8VDC-12VDC) power is connected BOTH via a diode (0.7VDC volt drop) to the (IN)put and via another diode to the ignition-powered instrument circuit.

The idea being that when the boat is in use, the gauge will be ignition powered and show the total number of hours:minutes:seconds the bilge pump has run since the last reset. When the boat is not in use, the gauge will be unpowered and dark, unless the float switch powers it along side the pump, in which case the pump circuit will power the pump, power the gauge, and serve as input to the chronometer to be counted. Since the chrony remembers the cumulative time, even when unpowered, the display will in fact be cumulative.

About the only catch is I don't know how these chronometers react when they hit 99:99:99. I'd like for them to stop there or show an overflow code -- but they might wrap around to 0 which could hide a problem after 4+ days of cumulative pump operation.

I obviously need fuses, but don't need to worry about the 0.7V drop across the diodes, as the nominal 12VDC input and power are good down to 8VDC. (Alternatively, I could also use a relay or transistor to let the pump and ignition circuit switch an always-on power circuit -- but that seems more complicated than need be).

So....my questions are these....

-- Why are cycle counters more common than run time counters, e.g. chornograph totalizers?

-- Why do people prefer counters to something like this? They seem more common?

-- Am I missing something? This seems like it is clearly the right way to go.

If you happen to be curious about that dripless shaft seal (DSS)....it isn't as big of a problem or surprise as it may seem.

When I bought the boat, the surveyor told me the boot, carbon stator, stainless rotor, clamps, etc, were all good. And, they all seemed good to me. But, although the boot felt soft and good, it didn't push the carbon very hard against the rotor. It just seemed to have gotten comfortable squished. So, it was on my radar.

I called the PO and the PPO and neither remembered ever replacing the boots, etc. And, together they went back almost two decades. When I had the boat hauled to do a thru-hull (I was out of town) they checked the boots and told me they were fine. So, I figured I do them in a year or so along with the bottom paint.

Well, that was a year ago. I still don't need bottom paint. But, may get it anyway while replacing the boots.

For now, I slid the boot and the rotor closer together to get more compression and pressure to seal and that solved the problem. I also ordered the maintenance kits. And, am working on scheduling the haul.

Many thanks!

-Greg