sdowney717

Guru

- Joined

- Jan 26, 2016

- Messages

- 2,264

- Location

- United States

- Vessel Name

- Old Glory

- Vessel Make

- 1970 Egg Harbor 37 extended salon model

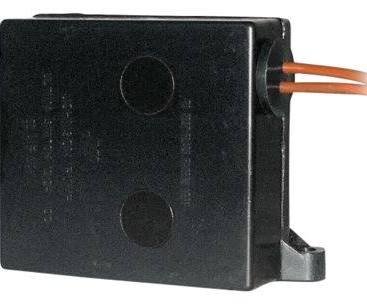

Top Liquid Water Level Sensor Right Angle Float Switch | eBay

Bought 2 of these right angled ones. You can also get straights.

Frankly speaking, I am tired of buying bilge pump switches. Just recently found one that is sticking on. If I lift float, it no longer drops.

These magnetic reed switch, I plan to connect to a couple 40 amp Bosch relays to power two 3700 Rule pumps. I just need an angled bracket.

I already power on the pumps using a relay, so this magnetic switch will act just like my manual switch.

I thought about straight inline switches. Maybe could be mounted inside an inverted cup for more protection. My current switches are all open float. I have 5 bilge pumps and all use your typical float switch.

This Ebay switch is sealed up waterproof. The float has a magnet that rips the switch. A Bosch relay takes 160 milliamps or less to energize it's coil. So easily this switch will power a relay.

Bought 2 of these right angled ones. You can also get straights.

Frankly speaking, I am tired of buying bilge pump switches. Just recently found one that is sticking on. If I lift float, it no longer drops.

These magnetic reed switch, I plan to connect to a couple 40 amp Bosch relays to power two 3700 Rule pumps. I just need an angled bracket.

I already power on the pumps using a relay, so this magnetic switch will act just like my manual switch.

I thought about straight inline switches. Maybe could be mounted inside an inverted cup for more protection. My current switches are all open float. I have 5 bilge pumps and all use your typical float switch.

This Ebay switch is sealed up waterproof. The float has a magnet that rips the switch. A Bosch relay takes 160 milliamps or less to energize it's coil. So easily this switch will power a relay.

Last edited: