kernr

Senior Member

- Joined

- May 29, 2020

- Messages

- 183

- Location

- United States

- Vessel Name

- Serenity

- Vessel Make

- Grand Banks 47 Europa

Good morning from the cold and very windy (today) Northeast -

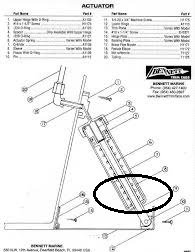

For the past several days I have been trying to clean up the trim tabs on the GB 47. According to the Bennett brochure they only move down from the stow position about 2 1/2". So it is very difficult to get in there and get all of the barnacles and other creatures out of there - yes, I unbolted the actuator hinges from the trim tab but it's still difficult. They look like they have 10 coats of ablative paint on them. I have removed the paint from the under side and was thinking a metal antifouling paint would be better for their preservation (already some minor pitting) than the typical bottom paint. Ideas on paint to use and if they need to be stripped of all paint prior to new pain. Also best way to remove old paint?

I've attached a few photos.

Thanks

Bob

For the past several days I have been trying to clean up the trim tabs on the GB 47. According to the Bennett brochure they only move down from the stow position about 2 1/2". So it is very difficult to get in there and get all of the barnacles and other creatures out of there - yes, I unbolted the actuator hinges from the trim tab but it's still difficult. They look like they have 10 coats of ablative paint on them. I have removed the paint from the under side and was thinking a metal antifouling paint would be better for their preservation (already some minor pitting) than the typical bottom paint. Ideas on paint to use and if they need to be stripped of all paint prior to new pain. Also best way to remove old paint?

I've attached a few photos.

Thanks

Bob