My two Lehman 120s always managed to get rid of the excess oil I had in them (until I learned better in the pre-internet days) by leaking it out into the drip pans. I was told that any excessive engine oil coming through the exhaust at idle would show up more like droplets hitting the water and spreading than the normal even sheen unburnt diesel displays. I cannot verify the veracity of this claim.

So changes I made over 29 years of ownership:

Got rid of those awful engine-mounted filters and replaced with a kit from Parker to allow a spin-on filter with a transparent bowl.

Changed the Racor 500 bowls to ones with the extra bulge for mounting a water sensor and wired in the Parker water sensor alarms to engines and genny Racors.

Replaced the injector pump drains with petcocks. My Simms pumps took exactly 2 cups to fill - never removed the overfill bolt again after that was established.

Replaced the original Lehman radiator caps with kits from American Marine for a double acting cap with a recovery bottle.

Replaced the sump plugs with hose connections to an electric oil change pump.

Replaced the original above engine muffler system (hopefully these abominations have been purged for all FL 120s nowadays) with lift mufflers.

Replaced all the black cooling hoses with blue silicone.

Replaced all coolers with high quality one made of cupronickel.

Added ball valves at the two points on the engine where the cooling water exited and reentered from the water heater in case there was ever a leak in that circuit.

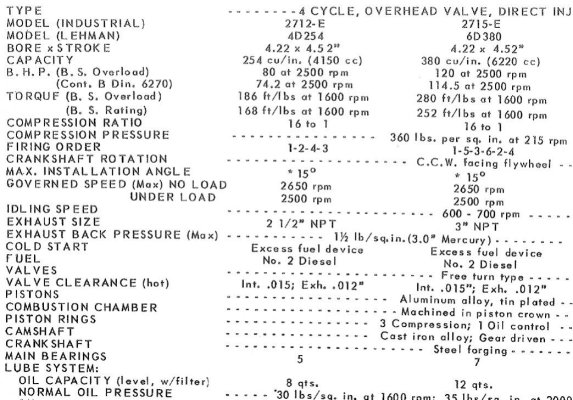

It is probably time for you to re-torque the head bolts and while the valve cover is of, check the valve clearances and hammer the valve cover flange flat using a steel ruler as a guide (to prevent nuisance oil leaks down the side of the engine - only 22 INCH pounds on the torque wrench to re-tighten the eight screws).

Be watchful for the first signs of rusty drippings from the bottom of the exhaust elbows onto the heat exchangers. That's time to change them, and it is not difficult unless you get a stuck bolt which a mechanic with an oxy torch can help you remove after you break it (Yes! I did

) Change both engines at once and put anti-seize on the four bolt threads when reassembling.

Pull the injectors for reconditioning before 2000 hours. Use new copper crushing washers in the bottom of the injector holes and on the return fuel banjo connections.

Use straight 30 weight oil, never synthetic or multi-weight. 40 weight if you will be in really hot waters, but here in north FL, I never needed it - 30 was fine.

50-50 ethylene glycol (Prestone for mine) coolant.

Lehmans return so little fuel that an installed polishing system becomes a fine idea to avoid contamination issues down the road. BTW, I used 2-micron Racor filters and had vacuum gauges remotely mounted from tees downstream of them so I could monitor them from the helm. With polished fuel, I went a year or two between Racor filter changes and five of more years for the spin-ons mounted on the engine.

There are likely a dozen other things I am not remembering right now, but I am always happy to shoot the sh__ about these great engines.