JDCAVE

Guru

- Joined

- Apr 3, 2011

- Messages

- 3,010

- Location

- Canada

- Vessel Name

- Phoenix Hunter

- Vessel Make

- Kadey Krogen 42 (1985)

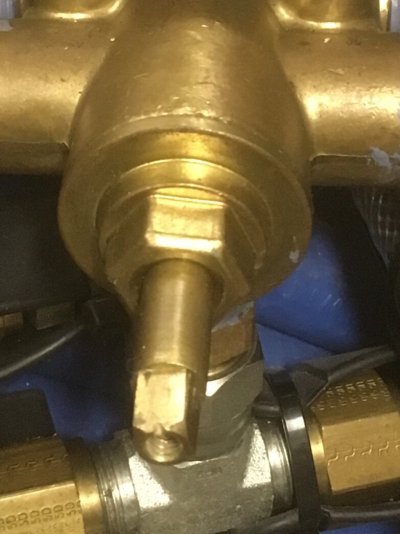

Can anyone recognize the make of this fuel selector valve. It seems the valve stem has worked its way out of the valve body about 3/4” and the handle no longer turns.

What it used to look like:

What it looks like now:

I had detached the mount to get a better look at the valve. Googling “Reverso” and fuel tank selector valve brings no luck. With the tanks shut off, I wonder if the the nut on the valve body can be backed off and the stem pushed back into place. Any thoughts on this? Possible replacement? Clearances are an issue in this location so fancy manifolds may be problematic.

Thanks Jim

What it used to look like:

What it looks like now:

I had detached the mount to get a better look at the valve. Googling “Reverso” and fuel tank selector valve brings no luck. With the tanks shut off, I wonder if the the nut on the valve body can be backed off and the stem pushed back into place. Any thoughts on this? Possible replacement? Clearances are an issue in this location so fancy manifolds may be problematic.

Thanks Jim