Cjbtrawler

Member

- Joined

- Nov 8, 2023

- Messages

- 6

New to the forum.

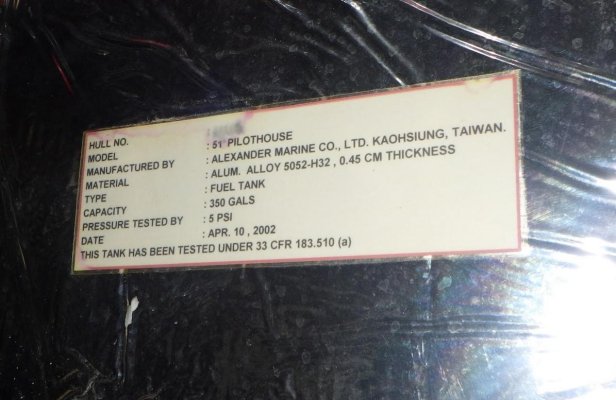

Im looking to purchase a trawler in the near future snd doing research at this point. Looking into the 2006 Ocean Alexander 50 Classico. I’ve been working with a broker who forwarded an 18 month old survey. The surveyor could not determine the material used to build the fuel tanks. I found that interesting but does anyone have any specifics for this series of boats?

Thanks

Im looking to purchase a trawler in the near future snd doing research at this point. Looking into the 2006 Ocean Alexander 50 Classico. I’ve been working with a broker who forwarded an 18 month old survey. The surveyor could not determine the material used to build the fuel tanks. I found that interesting but does anyone have any specifics for this series of boats?

Thanks