I’ve decided to mount my new strainer on a board and attach that board to the main starboard stringer on my fiberglass GB32.

I know the stringers are foam filled but they must be pretty strong to hold the weight of the motor.

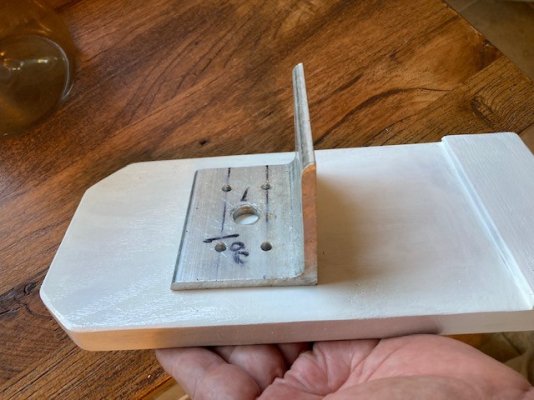

I’d like to attach the mounting board for the strainer with an L bracket using screws or lag bolts going down thru the top of the stringer. Bedded in of course.

Is this ok or a bad idea????

Someone has already used lag bolts to secure a mounting plate for a watermaker , and, I’m guessing the motor mounts attach somehow.

Anybody got any knowledge about mounting things to the stringers???

I know the stringers are foam filled but they must be pretty strong to hold the weight of the motor.

I’d like to attach the mounting board for the strainer with an L bracket using screws or lag bolts going down thru the top of the stringer. Bedded in of course.

Is this ok or a bad idea????

Someone has already used lag bolts to secure a mounting plate for a watermaker , and, I’m guessing the motor mounts attach somehow.

Anybody got any knowledge about mounting things to the stringers???