stroutmail

Senior Member

- Joined

- Apr 20, 2020

- Messages

- 154

- Location

- United States

- Vessel Name

- Grand Day Out

- Vessel Make

- Grand Banks 36 Classic

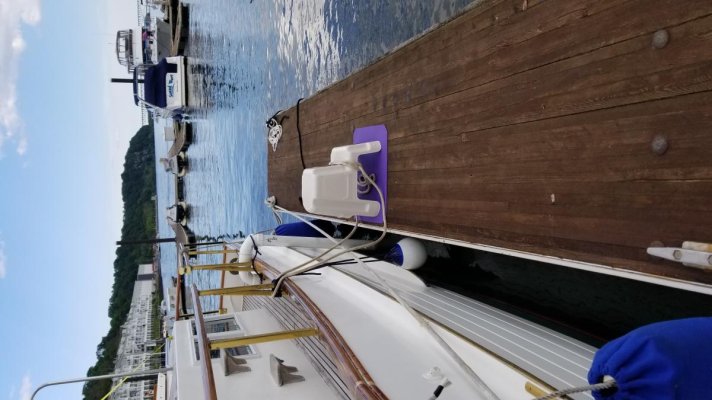

When first encountering the new to me Grand Banks 36, when attempting to board my wife looked a bit like a bull looking at a new gate. She managed to board but stated she could not get off without assistance. Not just the 24" drop having to step over the 9" gunwale, but also the distance out to the floating dock.

I kinda use the rub rail for a foothold, but it is a bit "uncertain".

I could just use a 2 or 3 step Taylor poly portable step which would solve the height, but not the distance out.

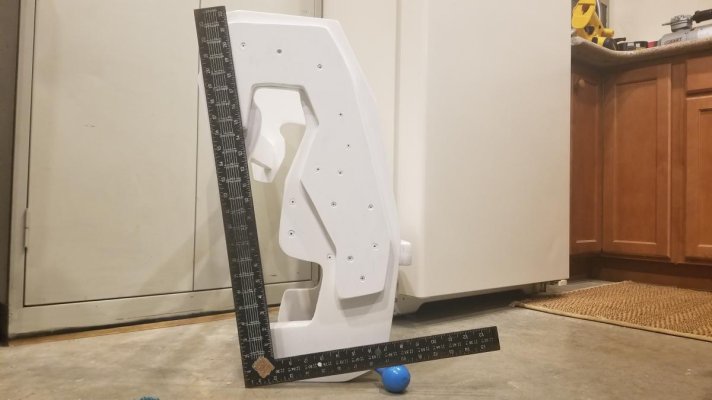

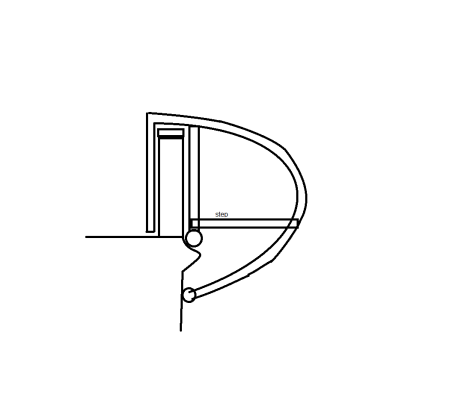

I wondered if anyone has found a step or has made one that attaches to or goes over gunwale and provides a full step out? The ladder below is the "over" the gunwale, or "attach to top of gunwale with keyhole mounting" concept. The drawing below is a sketch of a fabricated "step out" that would go over the gunwale with weight carried by the combination of gunwale, rubrail and torque supported by the insulated leg against the hull. I could make such a thing or similar out of wood or get someone to bend and weld some aluminum tubing. Or I could take the gunwale ladder like in the pic and modify it.

I would then also use a 1 or two step stool on the dock, and there would be less risk of it being pushed when crossing from the stool to the boat step.

I kinda use the rub rail for a foothold, but it is a bit "uncertain".

I could just use a 2 or 3 step Taylor poly portable step which would solve the height, but not the distance out.

I wondered if anyone has found a step or has made one that attaches to or goes over gunwale and provides a full step out? The ladder below is the "over" the gunwale, or "attach to top of gunwale with keyhole mounting" concept. The drawing below is a sketch of a fabricated "step out" that would go over the gunwale with weight carried by the combination of gunwale, rubrail and torque supported by the insulated leg against the hull. I could make such a thing or similar out of wood or get someone to bend and weld some aluminum tubing. Or I could take the gunwale ladder like in the pic and modify it.

I would then also use a 1 or two step stool on the dock, and there would be less risk of it being pushed when crossing from the stool to the boat step.

Last edited: