drexmac

Newbie

- Joined

- Jan 15, 2023

- Messages

- 4

- Vessel Name

- Sandpiper

- Vessel Make

- Californian 34

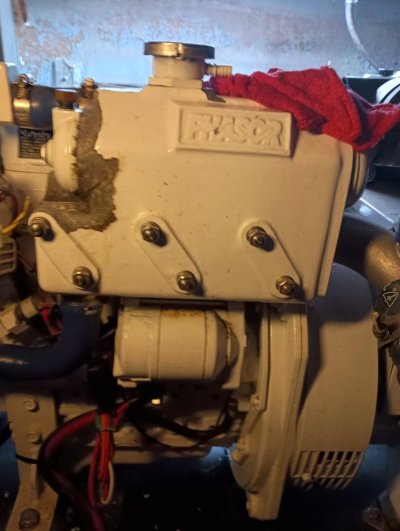

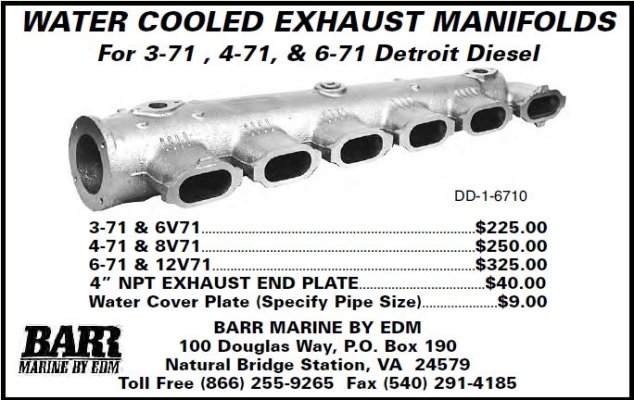

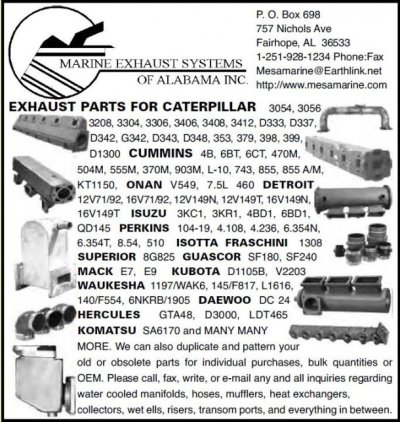

I have a Kubota phaser 6500 generator that has a crack on the heat exchanger / manifold. Apparently, it was not winterized correctly. It's cast iron, so weld repair is tricky. Before I remove it and start trying to find a welder who will take on the task, I was wondering if anyone has experienced a similar issue ? Am I able to seal it with something, like JB weld, gasket maker, etc?