Capt. Rodbone

Senior Member

- Joined

- Sep 6, 2020

- Messages

- 177

- Location

- U.S.

- Vessel Name

- SV Stella Polaris MV Sea Turtle

- Vessel Make

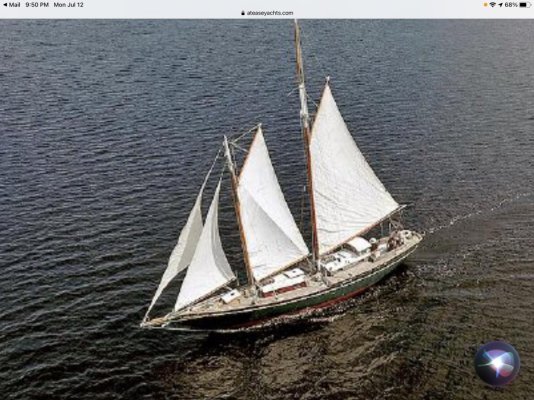

- 1978 VanDine Gaff rigged schooner, 1978 Grand Banks Classic Trawler

I’ve wooded down the cabin sides on our schooner. This is mahogany. I’m going to use Awlwood. It’s expensive but I love the look. At $400/gal I need it to last, and it will have a glossy finish that I’m afraid these cracks will show even more than they do now. Matching the color will be a challenge as well but I’ll experiment with that. Since these are vertical pieces, should I just use slightly thickened epoxy?I could also use wood filler, but my experience with “the stainable filler” is yes it’s stainable, but good lunch on matching it like you want. I’ve been sanding the surface so maybe let that be the thickener with the epoxy?

Picture below and it’s been explained to me in the past how to remedy this issue of a horizontal picture posting vertically but I don’t remember. These cracks in actuality run fore and aft, and yes I see the random orbital “ swirls” that need to be sanded out, but truthfully I didn’t in the bright sun, but did as soon as I looked at the picture.

Picture below and it’s been explained to me in the past how to remedy this issue of a horizontal picture posting vertically but I don’t remember. These cracks in actuality run fore and aft, and yes I see the random orbital “ swirls” that need to be sanded out, but truthfully I didn’t in the bright sun, but did as soon as I looked at the picture.