Hi Bucketlist1.

OK, you had a lab perform mechanical testing of two (2) samples of material, taken from an undocumented location of a 2018 Ranger 27 hull. The results of which are posted.

Some observations from an advanced-degreed professional mechanical engineer (me), with 45 years in the field of design, development, manufacturer, test, evaluation, use, blah blah blah of various fiber reinforced composite materials in marine use:

a. A sample size of two (2) is WAY fewer than necessary to develop a sound conclusion of the mechanical properties of this hull. Quality assurance practices require orders of magnitude more samples than you have presented to reach conclusions to the overall makeup of a composite part.

b. No information is presented on the location from which these samples were extracted. Doing mechanical testing on failed composites will inevitably yield sub-standard results. Should these samples have been extracted from a damaged portion of this hull, these tests are simply invalid to form any conclusions of the soundness of the laminate.

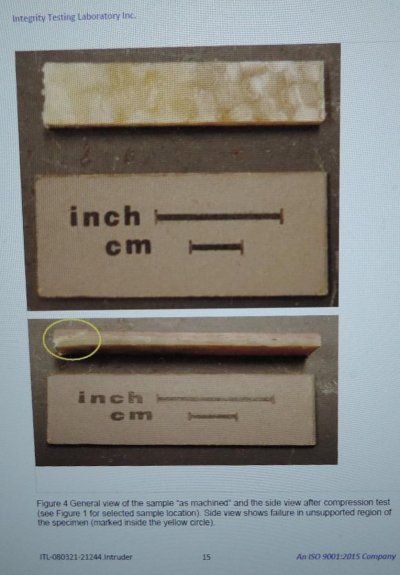

c. American Society for Testing Materials (ASTM) has developed standard coupon size for composites for a good reason. Substandard coupons (such as the two you submitted for testing) generate abnormal stress distributions within the tensile testing machine grips that skew results unacceptably. At least the picture of the one post-failure sample you provided appears to have failed in the necked-down region as expected. Pretty darn close to the grip end, however. Again, no reasonable conclusions can be extracted from the tensile tests, due to these anomalies.

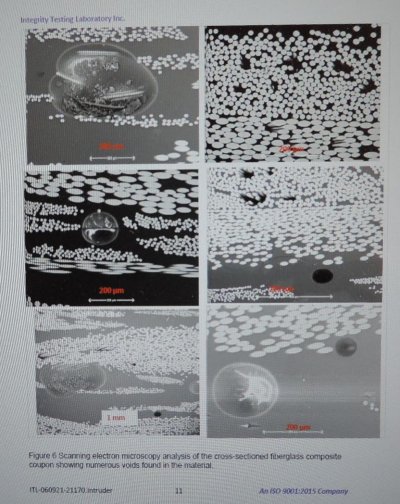

d. Voids appear in the matrix upon examination under a scanning electron microscope (SEM). Given that I do not know the exact method of manufacture by Ranger Tug, but can guess from decades of composite manufacturing experience, I suggest there are voids in ALL fiberglass reinforced composite materials typically used in mass produced recreational boat hull materials, similar to those you report. I do not explicitly know the quantity, size, and sample distribution of voids that is the norm for the industry, nor the norm for Ranger Tug. Thus your results are simply your results of a VERY limited sample. Again, no reasonable conclusions can be extracted from these SEM images.

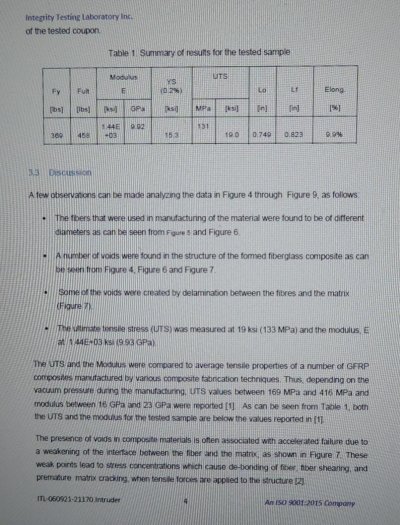

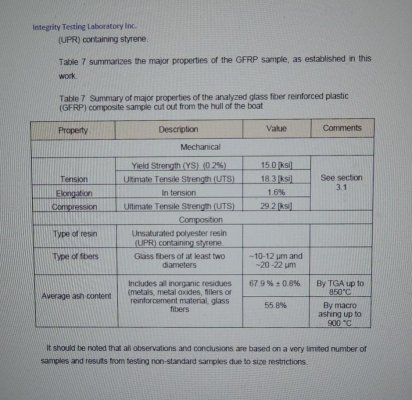

e. Laboratories are tasked to TEST materials, not form conclusions. That's for the professional engineers charged with evaluating the test results. Thus, your lab's "observation" (image 5) that your sample results are "...below the values reported" is improper. In particular, the reference [1] cited in your report could not be found in the information you provided. However, the lab makes reference to vacuum pressure during manufacturing of their referenced material values. But there's no indication that Ranger Tug uses vacuum in their manufacturing process. This is an improper observation (apples to oranges). The values this lab reported for your samples are simply what they are and cannot be used to conclude you particular samples are substandard.

Sorry to go on so long. Yes, your posting was interesting. But little else. If you're seeking affirmation that your particular boat has latent defects caused by manufacturing errors, you won't get them from me. It's unclear of your agenda from this posting, but I am very, very careful of putting into the public domain (i.e. this forum) information that is potentially damaging to others. Libel comes to mind.

Regards,

Pete

DSCN9079 (2).jpg175.9 KB · Views: 203

DSCN9079 (2).jpg175.9 KB · Views: 203 DSCN9080 (2).jpg147.9 KB · Views: 168

DSCN9080 (2).jpg147.9 KB · Views: 168 DSCN9081 (2).jpg105.3 KB · Views: 167

DSCN9081 (2).jpg105.3 KB · Views: 167 DSCN9082 (2).jpg94.8 KB · Views: 170

DSCN9082 (2).jpg94.8 KB · Views: 170 DSCN9083 (2).jpg161 KB · Views: 172

DSCN9083 (2).jpg161 KB · Views: 172 DSCN9084 (2).jpg142.4 KB · Views: 141

DSCN9084 (2).jpg142.4 KB · Views: 141 DSCN9085 (2).jpg101.4 KB · Views: 136

DSCN9085 (2).jpg101.4 KB · Views: 136 DSCN9086 (2).JPG155.9 KB · Views: 139

DSCN9086 (2).JPG155.9 KB · Views: 139