Simon J

Member

- Joined

- Sep 10, 2019

- Messages

- 8

- Location

- United States

- Vessel Name

- Simon J

- Vessel Make

- Morton & Hersloff 36

Winter project: Insulating the engine compartment of my 1978 Morton & Hersloff 36

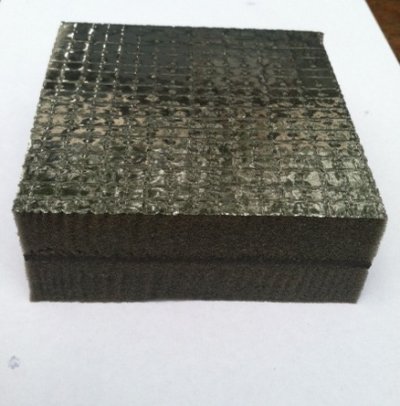

While insulating I came across old insulation- Lead backing with either fiberglass, or asbestos . Does anyone know if this could be asbestos? I am replacing all area easily within reach, but will go further if it is asbestos and should be removed. Also, I've heard that I can just remove Fiberglass?asbestos exterior and press my new insulation/heat shield /noise reduction diectly onto the lead backing.

Comments anyone??

Simon J

While insulating I came across old insulation- Lead backing with either fiberglass, or asbestos . Does anyone know if this could be asbestos? I am replacing all area easily within reach, but will go further if it is asbestos and should be removed. Also, I've heard that I can just remove Fiberglass?asbestos exterior and press my new insulation/heat shield /noise reduction diectly onto the lead backing.

Comments anyone??

Simon J