CaptainEd

Member

- Joined

- Dec 20, 2015

- Messages

- 15

- Location

- United States

- Vessel Name

- Sanctuary / Misty

- Vessel Make

- 58 Hatteras MY / 41 Hatteras Convertible

EDIT: Model number is Model is 8-E32OZD

This generator will be the death of me.

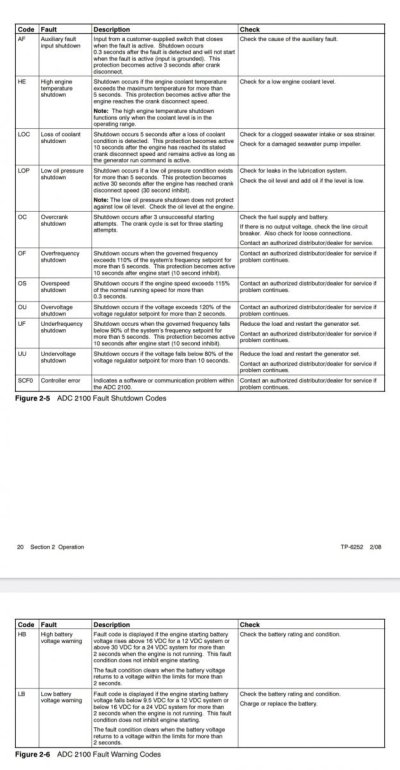

So I started it to warm it up for a simple oil change. After about 90 seconds it quit with the LOC code on the display. Did some research, looks like the most common cause is low water flow, even though it can look fine coming out of the side of the boat (it did look fine).

Checked the coolant level, it fine.

So next I tackled the seacock/thru-hull. Well, indeed it was restricted by something, which I was eventually able to clear. Hooked everything back up, started it, notice even better water flow, and it quit again, same error.

Next, the impeller. I found one blade missing and upon pulling it, found the blade in the outlet port of the pump. Great! It didn't get sent to the heat exchanger! Put everything back together, started it, terrific water flow, and it quit again.

I'm going to pull the cap off the heat exchanger next but i doubt I'll find anything. In the meantime I thought I would tap the collective for any other ideas.

Also, if anyone knows how to bypass the sensor for this I would appreciate the knowledge. I don't know that I'm going to be able to find a replacement in stock to continue the trip.

Running without it isn't an option in this Miami heatwave. I have to have a charging source as well since the alternator seems to have taken a crap too.

Thanks,

-Ed G.

Thanks,

-Ed G.

This generator will be the death of me.

So I started it to warm it up for a simple oil change. After about 90 seconds it quit with the LOC code on the display. Did some research, looks like the most common cause is low water flow, even though it can look fine coming out of the side of the boat (it did look fine).

Checked the coolant level, it fine.

So next I tackled the seacock/thru-hull. Well, indeed it was restricted by something, which I was eventually able to clear. Hooked everything back up, started it, notice even better water flow, and it quit again, same error.

Next, the impeller. I found one blade missing and upon pulling it, found the blade in the outlet port of the pump. Great! It didn't get sent to the heat exchanger! Put everything back together, started it, terrific water flow, and it quit again.

I'm going to pull the cap off the heat exchanger next but i doubt I'll find anything. In the meantime I thought I would tap the collective for any other ideas.

Also, if anyone knows how to bypass the sensor for this I would appreciate the knowledge. I don't know that I'm going to be able to find a replacement in stock to continue the trip.

Running without it isn't an option in this Miami heatwave. I have to have a charging source as well since the alternator seems to have taken a crap too.

Thanks,

-Ed G.

Thanks,

-Ed G.

Last edited: