BajaTrawler

Veteran Member

Recently, I purchased a set of rebuilt fuel injectors from American Diesel, and took them with me to La Paz, Mexico, where I keep the boat. My Lehman has 4000 hrs. on the meter now, and although it was running ok, with just a bit of smoke at startup, and a bit of fuel sheen on the water, I figured it was time to replace them.

Bob Smith at AD was very helpful in an MTOA post, explaining the steps and suggesting techniques to make the job easier. Three of the more important suggestions he made: remove the 2 bolts holding the secondary filters and move them out of the way, to provide access to #6 injector. If you don't do this , it would be VERY hard to remove #6; remove the injection tubes as units and invert them in the overturned valve cover to prevent loss of fuel and easier priming when finished; and also to pressure test the fuel return rail connections to check for leaks after reassembly.

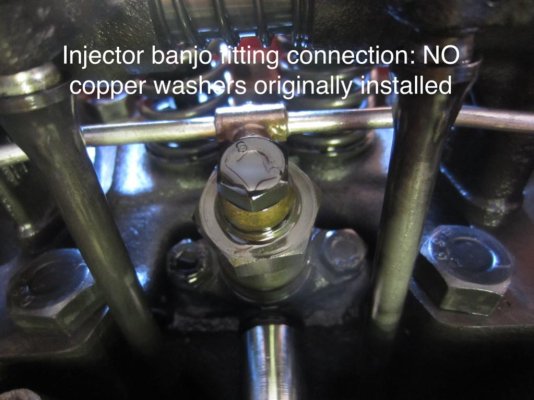

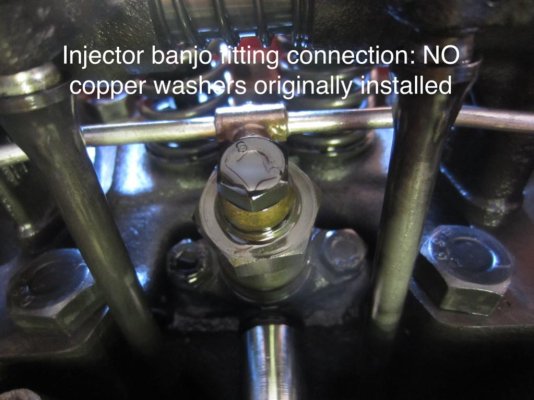

Having a rebuilt set of injectors before commencing work was very beneficial. The new set had very small copper washers (1/4" OD) that seal the fuel rail slotted bolts and banjo fittings to the injectors. I knew that I would drop at least a couple washers down a pushrod tube or other inaccessible location, so I stuffed paper towels into all the holes. Amazingly, nothing was dropped! But, I did discover that the previous installation, whether original or by a previous owner, DID NOT include these copper washers! Why the connections did not leak I don't know, or maybe they did, but such a small amount as not to be noticed in the pan oil level. Hence, Bob's suggestion to pressure test the connections after reassembly.

I found that the easiest way to remove the injectors after disconnecting everything, was to use a 7/8" or maybe it was 1" socket, to turn the injectors gently back and forth to break the carbon accumulation on the tip inside the head. Then, wiggle them with a pair of channel locks until they could be lifted out. Each came out with it's old copper sealing washer attached. Don't think they could have been removed by prying with screwdrivers.

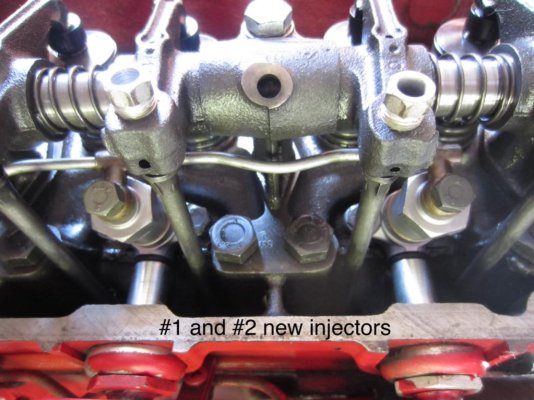

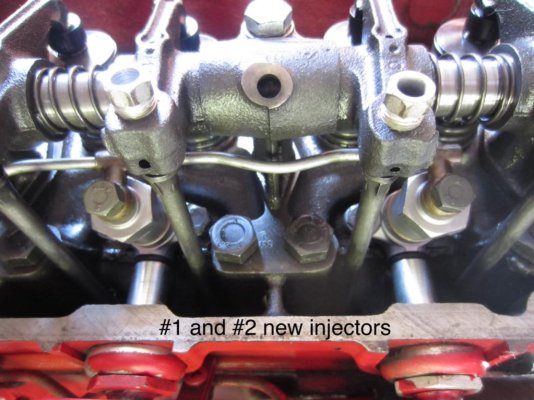

Installing the new injectors was straight forward. Each got a new tip copper washer, and 2 return fuel banjo fitting washers. All fittings were torqued to the specs in the Lehman manual. It wasn't necessary to remove the valve pushrods because access was adequate to remove and install all components.

To pressure test the fuel return connections, I attached a bicycle pump to the fitting on the outside of the head and pressurized for a few minutes.

Bob Smith at AD was very helpful in an MTOA post, explaining the steps and suggesting techniques to make the job easier. Three of the more important suggestions he made: remove the 2 bolts holding the secondary filters and move them out of the way, to provide access to #6 injector. If you don't do this , it would be VERY hard to remove #6; remove the injection tubes as units and invert them in the overturned valve cover to prevent loss of fuel and easier priming when finished; and also to pressure test the fuel return rail connections to check for leaks after reassembly.

Having a rebuilt set of injectors before commencing work was very beneficial. The new set had very small copper washers (1/4" OD) that seal the fuel rail slotted bolts and banjo fittings to the injectors. I knew that I would drop at least a couple washers down a pushrod tube or other inaccessible location, so I stuffed paper towels into all the holes. Amazingly, nothing was dropped! But, I did discover that the previous installation, whether original or by a previous owner, DID NOT include these copper washers! Why the connections did not leak I don't know, or maybe they did, but such a small amount as not to be noticed in the pan oil level. Hence, Bob's suggestion to pressure test the connections after reassembly.

I found that the easiest way to remove the injectors after disconnecting everything, was to use a 7/8" or maybe it was 1" socket, to turn the injectors gently back and forth to break the carbon accumulation on the tip inside the head. Then, wiggle them with a pair of channel locks until they could be lifted out. Each came out with it's old copper sealing washer attached. Don't think they could have been removed by prying with screwdrivers.

Installing the new injectors was straight forward. Each got a new tip copper washer, and 2 return fuel banjo fitting washers. All fittings were torqued to the specs in the Lehman manual. It wasn't necessary to remove the valve pushrods because access was adequate to remove and install all components.

To pressure test the fuel return connections, I attached a bicycle pump to the fitting on the outside of the head and pressurized for a few minutes.