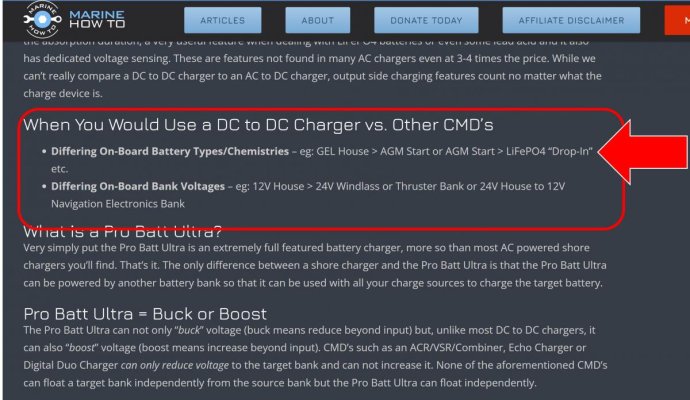

Three items here: First, dealing with disparate chemistries (LFP to FLA or AGM - domain of DC-DC chargers). Second, cooking an alternator due to regulation geared towards FLA/AGM. And third, cable size to handle the larger currents, especially since LFP are smaller so more battery will fit into the space where AGM/FLA house bank used to reside.

I agree that if all three things are already in place, LFP are drop-in. Disagree that 95% of the boats already have all three. In fact, I'd guess 5% is a better guess. But since that puts me into the group of people that apparently "have little knowledge of the subject," perhaps you can enlighten further? I don't claim to be an expert, but nor do I consider myself grossly out of touch. What am I missing?

Peter

I think this is worth expanding on.

LFP has some differences due to battery behavior of the chemistry.

LFP introduces an BMS which under fault conditions will disconnect the battery. You need to ensure that won't cause damage to other parts of your electrical system.

LFP is typically motivated by a desire to have more battery capacity, which is often linked to a desire to have more inverter capacity. In short, people switching to LFP is typically looking to enlarge (sometimes quite significantly) their whole power system. This drives most of the change in systems, from what I have seen, and it is drive by wanting a larger power system, not because you are switching to LFP. Building a bigger power system using lead batteries will trigger all the same changes as using LFP, with the exception of handling BMS fault condition.

In this context, let's look at the typical changes that people make, or struggle with:

Overloading Alternators: This is partly because you want a higher capacity battery bank, and partly because you are switching to LFP. But as Delfin points out, any big LA bank will be just as capable of cooking an alternator. Most alternators are designed with the assumption that they won't run at full output for very long before the battery bank reaches absorb, and the output demand will drop. They are designed to survive just long enough at full power to reach absorb. With a start bank, this will happen quickly. With a house bank, it will depend on DOD, and size of the bank. It doesn't take long before the alternator can't survive long enough to get to absorb, so anyone implementing a large house bank will likely have already switched to an external regulator that can be manually derated and/or derated based on sensed alternator temperature. LFP does make this problem harder because there is no absorb stage, or at least none to speak of. Charging is balls to the wall right up until they are full.

So if you find yourself somehow needing to regulate alternator output because you don't have an external regulator, understand that it's as much to blame on a larger battery bank as it is LFP. If you already have an external regulator, then this aspect of switching from LA to LFP is trivial.

Different Charge Profiles: LA and LFP have different charge profiles, but so do FLA and AGM. So switching to LFP is really no different than switching from FLA to AGM for your house bank. You will need to charge each bank according to its own rules, or lump them together and compromise one or the other. You pick.

BMS Disconnect: This is unique to LFP, no doubt. But it's also no different than a fuse blowing and disconnecting your house bank. In the later case we live with the risk, but in the former case we get all twiterpated about it. I think a really important thing to remember is that a BMS disconnect is not an end of charge indicator. It's a fault indicator. If you are charging anywhere near the BMS disconnect point, stop doing that. If your BMS is disconnecting, figure out why and fix it. Now I am NOT saying you shouldn't protect against a disconnect, just trying to emphasize that it's a fault condition, not normal operation. With that in mind, there are a variety of solutions, my own favorite being use of a disconnect warning signal from the BMS to turn off the alternator. This is increasingly available, even from so-called drop-in batteries.

So to sum it up, when massive electrical system changes are required, it's probably 80% because you are enlarging your electrical system, and 20% because you are using LFP.