Teak deck seams

When we bought our ‘03 42’ Europa all the seams were proud. If you take a really close look you’re probably find the bonds between the seam & teak plant partially compromised. Translation: gaps between the seam & teak plank. We used Jeff Gibbs Teak, known you be the best re-seamer in Fort Lauderdale, FL.

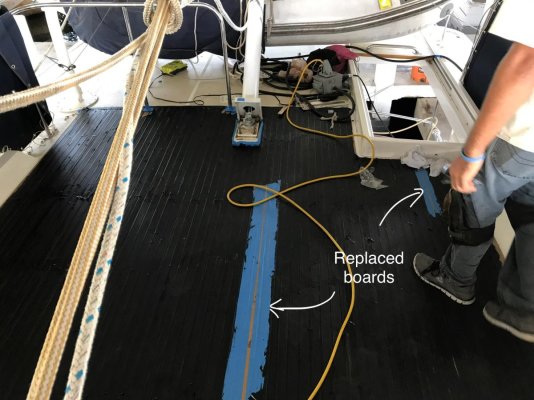

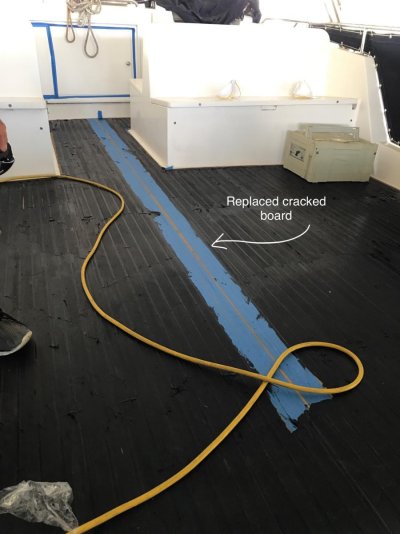

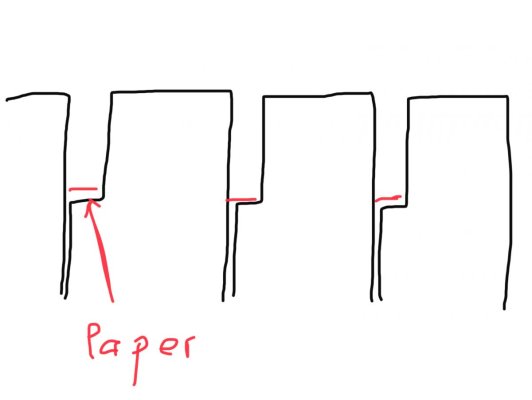

They pulled the seam on the outermost board manually & then used that seam as a reference & used a custom adjustable fence to guide a feintool router and removed all material. To prep the seam before caulk they cleaned the seam with acetone and then laid a thin paper strip in the opened seam. This insures that when the deck works there is equal pulling force in the bond. After completing a large area they applied sealant over the entire deck similar to applying grout over tile. When fully cured they used that wonderful feintool sander and lightly sanded all the caulk down to the teak. A remarkable process.

Another member in our club had a Grand Banks 42 and he ripped all the decks off and replaced with synthetic teak. What struck me was how difficult it was to rip up the old teak. It was solidly glued to the deck. That convinced me that Grand Banks laid the deck into thick adhesive and the screws were to used to secure the deck into the adhesive. One secured the screws are a irrelevant as long as the teak deck has not been compromised with water getting under the deck and compromising bond.

Similar to my boat, your bangs are in good shape so they’re not popping out, so there’s no concern about the screws being loosened. The trick is to keep the seam integrity.

I apologize for the detailed report but wanted to give you some insight regarding how the GB teak deck is constructed.

By the way, Jeff Gibbs was absolutely insistent, emphatically so, DO NOT CLEAN teak decks with teak cleaner. Do not oil. The wood is oily enough. He said the best cleaner to keep teak decks healthy is salt water. If you absolutely must remove some of the surface grime he recommended cascade dishwashing detergent crystals. It doesn’t destroy the teak/caulk seem integrity. The reason your teak seams are proud is the decks have been cleaned often. When you clean teak decks you’ll see, even with salt water w/ light brush and nothing else, the water runoff is brown. That is dirt AND teak pulp going down the drain.