HeadedToTexas

Guru

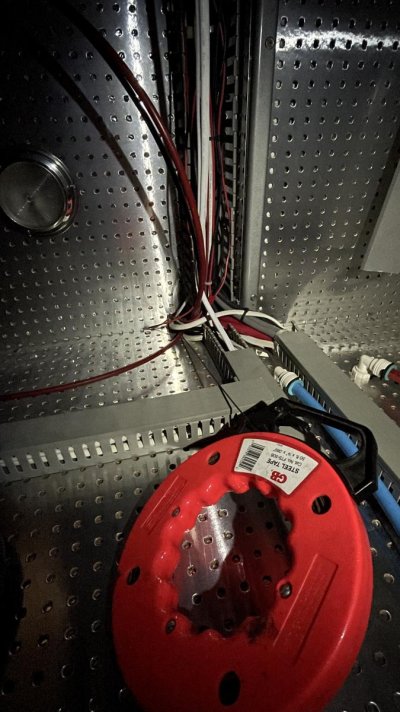

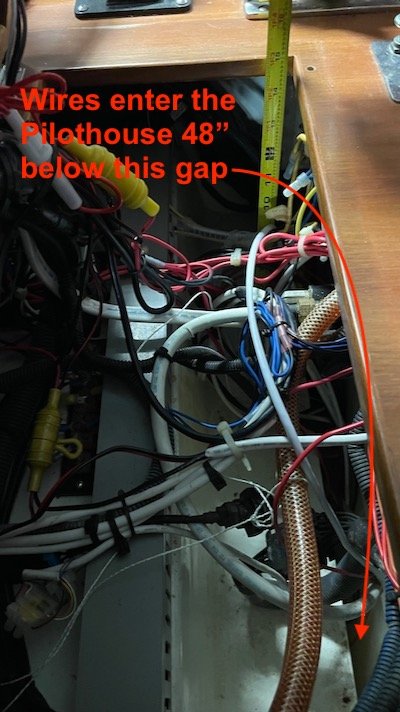

The engine room of my 2007 Mariner 37 (Helmsman 38) is lined with aluminum faced insulated “pegboard” material. What is the best way to pull nearly an inch worth of cables through an already tight passage between the ceiling of the engine room and the chase between the pilothouse bulkhead and the aft face of the shower? I got the bundle to the tight spot, but no further. Visualizing the actual hole is almost impossible.