Pmcsurf1

Senior Member

I've heard diesel engines like heat. I understand. We're traveling the loop and drive 4 to 6 hours at around 1800 rpms. Some say you gotta run the engine up to 80 percent for about an hour to burn out the carbon. I try to comply. Usually with 30 mins or so to go ill run the engine up to 2600 or 2700 rpm. Max is 3400. This makes a huge wake and burns tons of fuel. This makes no one happy. BTW boat is a MS400 and single engine is a Yanmar 6lya-stp 370hp.

Now I read in the manual the you should race the engine up and down for 5 min before shutting down. This is copied from a Yanmar manual.

When operating the engine at low speed for long periods of time, race the engine once every 2 hours.

How to Race the Engine

Repeat a cycle of high speed and low speed operation about 5 times at no load with

the clutch (marine gear) in Neutral position.

Engine racing removes carbon deposits from the cylinder and the tip of the fuel

injection valve.

If racing is neglected, the exhaust color may worsen and performance may drop.

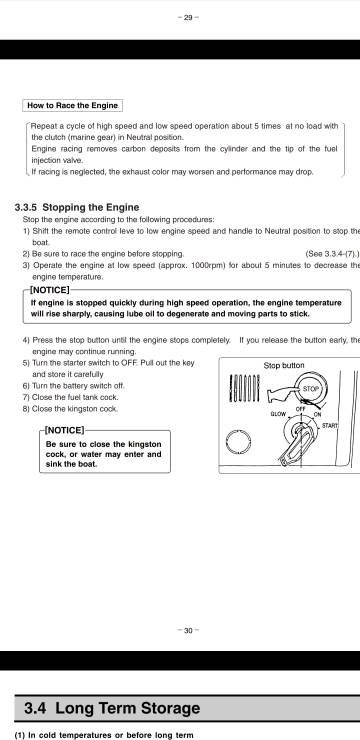

3.3.5 Stopping the Engine

Stop the engine according to the following procedures:

1) Shift the remote control leve to low engine speed and handle to Neutral position to stop the

boat.

2) Be sure to race the engine before stopping. (See 3.3.4-(7).)

3) Operate the engine at low speed (approx. 1000rpm) for about 5 minutes to decrease the

engine temperature.

Okay, anyone do this? I've never heard boats racing their engine after pulling into a slip.

Also, it doesn't say how many rpms for how long.

Thoughts?

Now I read in the manual the you should race the engine up and down for 5 min before shutting down. This is copied from a Yanmar manual.

When operating the engine at low speed for long periods of time, race the engine once every 2 hours.

How to Race the Engine

Repeat a cycle of high speed and low speed operation about 5 times at no load with

the clutch (marine gear) in Neutral position.

Engine racing removes carbon deposits from the cylinder and the tip of the fuel

injection valve.

If racing is neglected, the exhaust color may worsen and performance may drop.

3.3.5 Stopping the Engine

Stop the engine according to the following procedures:

1) Shift the remote control leve to low engine speed and handle to Neutral position to stop the

boat.

2) Be sure to race the engine before stopping. (See 3.3.4-(7).)

3) Operate the engine at low speed (approx. 1000rpm) for about 5 minutes to decrease the

engine temperature.

Okay, anyone do this? I've never heard boats racing their engine after pulling into a slip.

Also, it doesn't say how many rpms for how long.

Thoughts?