f508

Senior Member

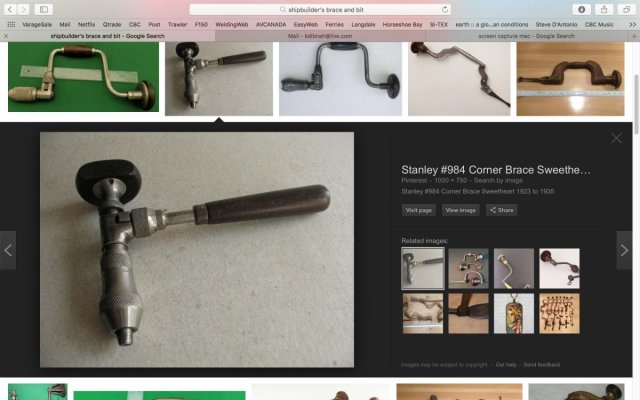

I am looking for a source for some brace bits to use to turn the bronze and stainless screws on my boat. They tend to be pretty large, 1/2" or 3/8" in diameter. It feels like if I try to work them with the standard 1/4" tool bit the heads will strip. It seems like that has to be a source for 3/8" and 1/2" diameter bits, but I can't find one. I suspect I am using the wrong terminology for my search.

Thanks,

Frank

Thanks,

Frank