jefndeb

Guru

Just an FYI,

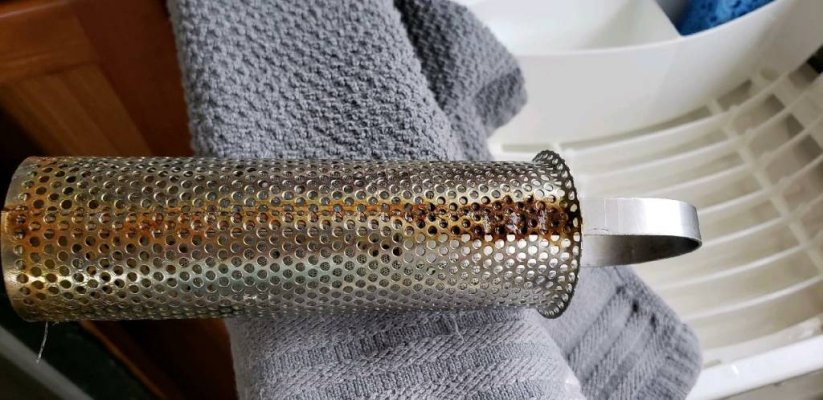

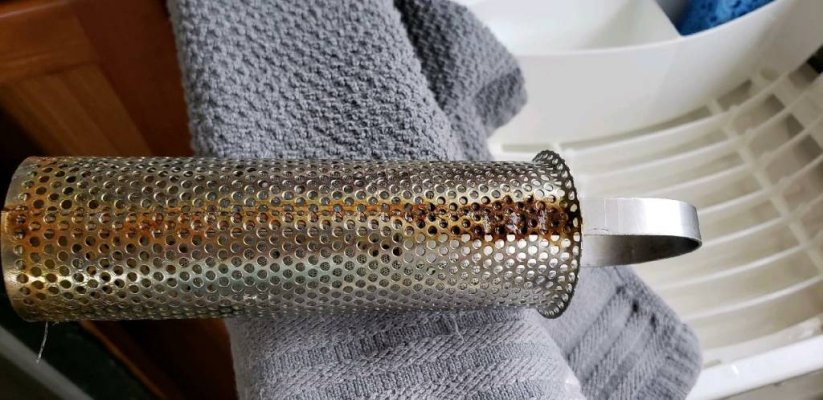

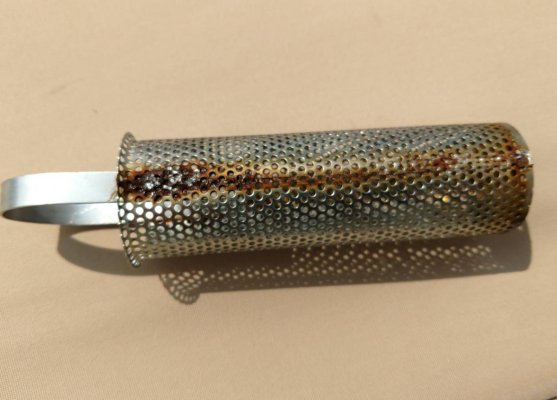

We replaced our AC strainer basket 3 weeks ago, ordered from sure marine, and it is already rusting...I called sure marine to ask what the deal was and they refered me to their supplier "Marine Hardware".

They said it's made with 304 SS and will rust in salty or brackish water....what??

No help there...they said if I don't like it just return it....wow.

Looks to me it is rusting where the finger loop is soldered or welded to the basket.

Dissimilar metal corrosion?

I wish Marine Hardware offered a plastic basket like Groco does.

Furthermore I wish my Mainship had groco strainers.

Oh well...it is what it is.

Just thought I would share that.

We replaced our AC strainer basket 3 weeks ago, ordered from sure marine, and it is already rusting...I called sure marine to ask what the deal was and they refered me to their supplier "Marine Hardware".

They said it's made with 304 SS and will rust in salty or brackish water....what??

No help there...they said if I don't like it just return it....wow.

Looks to me it is rusting where the finger loop is soldered or welded to the basket.

Dissimilar metal corrosion?

I wish Marine Hardware offered a plastic basket like Groco does.

Furthermore I wish my Mainship had groco strainers.

Oh well...it is what it is.

Just thought I would share that.

)

)