Wdeertz

Senior Member

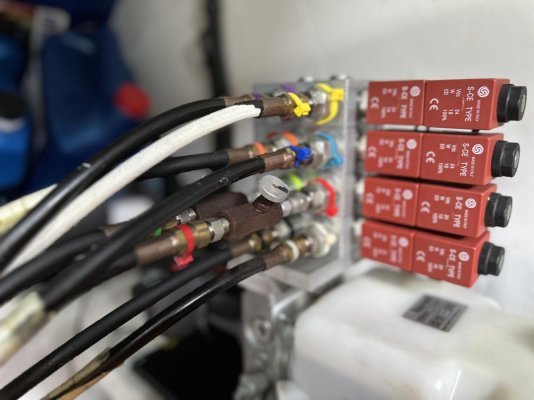

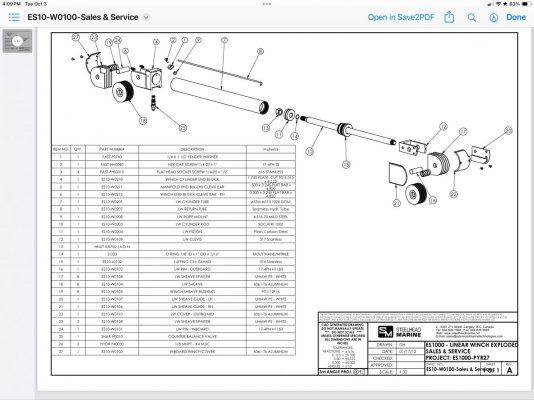

I replaced the dynema line on my steelhead ES1000 davit last year. Prior to replacement all functions on the davit were 100% working. After line replacement the winch line would slowly extend while under heavy load. I suspected this was due to air in the hydraulic lines. Looking at the manual it says the hydraulic lines are self bleeding after running the line in/out 3 times which I did. The slippage has been getting progressively worse over the last year so not sure if my issue is air in the line or some other issue. While looking at the central manifold/pump I noted two of the line have what appear to be valves on them. Not sure if these lines are for the winch control or the boom or extension. Both boom and extension movements fully hold under load.

Anyone with experience with this davit that can offer some suggestions on possible solutions?

Anyone with experience with this davit that can offer some suggestions on possible solutions?