I think the most common problem w BW gears is oil seals.

Most or all the early synthetic lube oil problems w seals have been solved so there shouldn't be any problems w the syn gear oil. However from what I've read they put in an additive to counteract the swelling, hardeding or whatever the seal problem was or would still be w/o the additive. Like VI additives I'm sure this additive has little or no lubricating qualities but if there was any mistake in adding the stuff questionable results could happen.

The only reason to use syn is for high heat applications like racing engines or cars/trucks pulling a heavy trailer up a steep mountain pass in the desert. But unless there's something wrong w your equipment temps experienced in slow speed yachts run by old men should be way below the temps that need or benefit from syn lubricants.

Since you don't need it for heat and there's a remote chance it could cause seal problems regular Automotive trans oil is totally adequate and IMO a better choice.

Yes, trans certainly does not get as hot as a car or truck. Every 20* temp drop in them I read doubles their expected life if they experience high temperature running.

I rebuilt one velvet drive myself due to a leak. Rust had built up on cast iron pump body surface causing the black square O-ring to weep fluid. they are very simple inside compared to auto trans construction.

All the seals, rubbers, friction plates were in such good shape, like new, I saved them.

My thinking with synthetic is a friction reduction, so ever so slightly improved HP transfer to the props.

I checked my fluid and it had been a few years. It was a beautiful clear red.

Dexron III, is what I use. The fluid looks so good, I don't think it is worth changing. They are the older style series 72c inline velvet drives with 2.57 to 1 reduction gears.

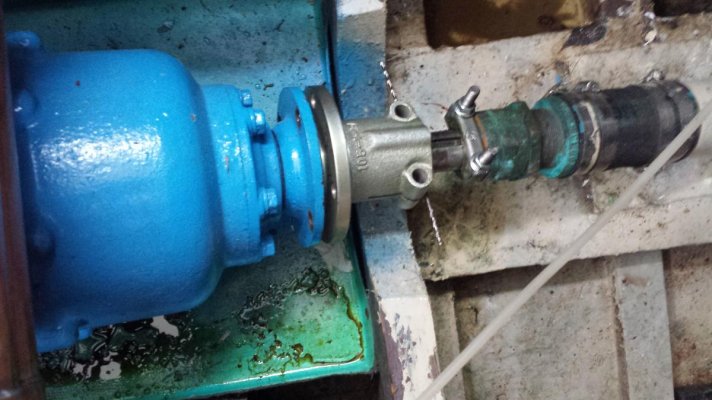

This month I replaced the shaft coupling with a split one. You can see the bolt on flange in the reduction unit which signifies it is the older style gear reduction.

I like the split coupler so much more. It is beefier, a real strong design. My runout is now .000 to .002 between the flanges. I am hoping that means my shaft is not bent.