2 banks of new batteries. #1 bank is two group 24s starting batteries in parallel with a total of 1600 CCA. #2 bank is 2 deep discharge golf cart batteries in series.

Cleaned up and/or replaced all battery power and ground cables. Cleaned up all generator and alternator connections.

Cleaned all of the engine connections including the starting button on the starboard engine at the upper helm.

Still have to hit the starter button 3-4 times on either engine to get the starter engaged and turning the engines. The engines start instantly once the starter turns the engines.

Shorted across the solenoid battery input and output connections and got strong starter motor spin. Can hear both solenoids mechanical "clicks" when I hit the start button on both engines. So, it sounds like the solenoids are not stuck.

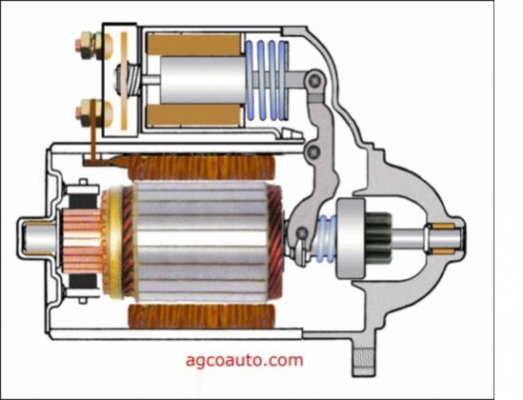

Starting to think I need to rebuild both AC Delco starters. Either the solenoids internal electrical contacts are bad or the starter brushes are gone.

I still need to clean up the start button connections on the port engine, but the connections have been cleaned on the starboard engine. I am having the same issue with both engines.

It's kinda hard to believe both starters would fail at the same time, but that is all I can think of after all I have done.

Your thoughts are appreciated.

Cleaned up and/or replaced all battery power and ground cables. Cleaned up all generator and alternator connections.

Cleaned all of the engine connections including the starting button on the starboard engine at the upper helm.

Still have to hit the starter button 3-4 times on either engine to get the starter engaged and turning the engines. The engines start instantly once the starter turns the engines.

Shorted across the solenoid battery input and output connections and got strong starter motor spin. Can hear both solenoids mechanical "clicks" when I hit the start button on both engines. So, it sounds like the solenoids are not stuck.

Starting to think I need to rebuild both AC Delco starters. Either the solenoids internal electrical contacts are bad or the starter brushes are gone.

I still need to clean up the start button connections on the port engine, but the connections have been cleaned on the starboard engine. I am having the same issue with both engines.

It's kinda hard to believe both starters would fail at the same time, but that is all I can think of after all I have done.

Your thoughts are appreciated.