I agree with DavidM, and note that there are likely a bunch of more detailed considerations. It all sounds like an interesting project.

- Are these internally regulated alternators? If so, they will likely contribute equally through the portion of charging that will accept full output from the alternators (bulk, in the case of a multi-stage regulator) Once beyond that where less than full output can be absorbed by the batteries, their contributions will almost certainly be unbalanced, and at times might be very unbalanced. But it really doesn't matter as far as charging your batteries is concerned.

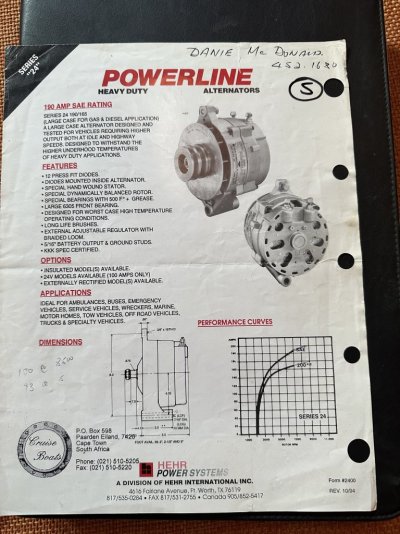

- Are they externally regulated? If so, I would use a single regulator and have the field output drive both alternators in parallel. That will provide equal (as close as possible) contribution from both alternators, all the time. You will also probably get quicker battery recharge times.

- An 11kw engine is pretty small. Is this a stand-alone engine just for the alternators, or is used for other things too? I ask because most alternators are pulley-driven, and nearly all engines have limits on how much power you can take off of pulleys. You didn't mention the voltage, but even at 12V you talking about more than 50% of the engine's power, and at 24V you will probably be able to fully load the engine. On most engines you can only take full load directly in line with the drive shaft.