Oil Gypsy

Veteran Member

- Joined

- Sep 25, 2019

- Messages

- 55

- Location

- Canada

- Vessel Name

- Dauntless

- Vessel Make

- Grand Banks 36 Classic #248

Hi,

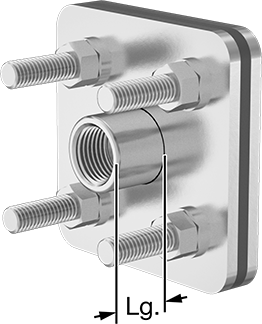

On my 1971 Grand Banks 36 I have been trying to refurbish the domestic water system. While removing the tanks side discharge valves it became apparent that all was not well, the valves could not be closed and the fittings seemed heavily corroded. The boat is equipped with 2 x 85 Gall stainless steel tanks, the discharge fitting seems to consist of an external brass fitting riveted and braised to the side of the tank with threaded female connection to install the valve.

On the port tank the fitting seems to have suffered from some form of electrolysis, while attempting to unscrew the old valve the fitting disintegrated, I'm left with a 1" hole and three smaller holes where the rivets were installed.

Has anyone faced this problem and what fitting have you used to replace the original.

Thanks

On my 1971 Grand Banks 36 I have been trying to refurbish the domestic water system. While removing the tanks side discharge valves it became apparent that all was not well, the valves could not be closed and the fittings seemed heavily corroded. The boat is equipped with 2 x 85 Gall stainless steel tanks, the discharge fitting seems to consist of an external brass fitting riveted and braised to the side of the tank with threaded female connection to install the valve.

On the port tank the fitting seems to have suffered from some form of electrolysis, while attempting to unscrew the old valve the fitting disintegrated, I'm left with a 1" hole and three smaller holes where the rivets were installed.

Has anyone faced this problem and what fitting have you used to replace the original.

Thanks

You basically made that mcmaster & carr piece out of starboard! I take it you did have access ports then, made it much easier. What's holding the copper pipe into the starboard, did you thread the starboard?

You basically made that mcmaster & carr piece out of starboard! I take it you did have access ports then, made it much easier. What's holding the copper pipe into the starboard, did you thread the starboard?