STB

Guru

Hey All,

This is just a note for anyone it may help.

The Kohler 6EOD generator (and likely any others from Kohler using the ADC 2100, among others) has a digital gauge kit that uses the standard CAN/J1939 interface.

I didn't want to pay ~$800-$900 for the Kohler digital gauge kit, which contains a single multi-purpose digital gauge, especially since I'd need two of then to have one at each helm. So, I ordered the Yacht Devices YDEG-04 to take the data from the J1939 interface and put it onto my NMEA2000 (ST-NG) bus where my chart plotters and Raymarine i70 and other instrument can show it, as can my OpenCPN instances.

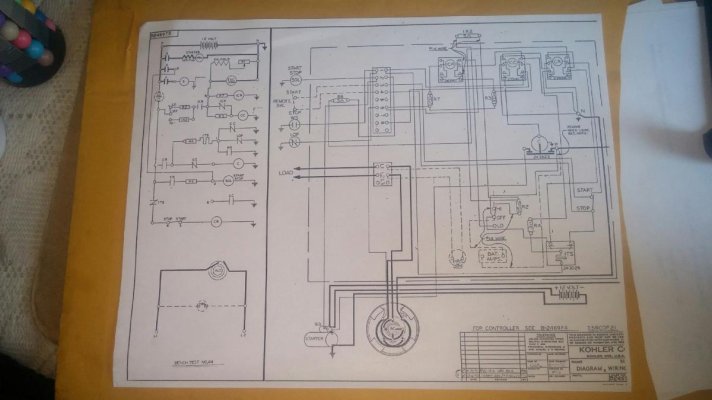

I hooked CAN_H to pin 1 (yellow) and CAN_L to pin 2 (Green) and the cable shield to pin 9 of the genset's Customer Interface Connector (CIC).

That, by itself didn't work, so I added a 120-Ohm resistor across the CAN_H and CAN_L on the second and otherwise unused of the "Y" connectors on the YDEG-04, and magic happened.

A 120-Ohm terminating resistor is typical for each side of a CAN bus to dampen signal reflections on the wire. In this case, after poking for a bit at the wires coming from the controller, I think the current through the resistor somehow turns on the interface on the controller. I didn't see much until it was there.

I mention this because the instructions with the YDEG-04 were seemingly written with an underlying assumption that one is attaching to an existing and properly terminated CAN bus versus creating a new one connecting the YDEG-04 and the genset. As a result, they don't mention that resistor as part of the installation instructions.

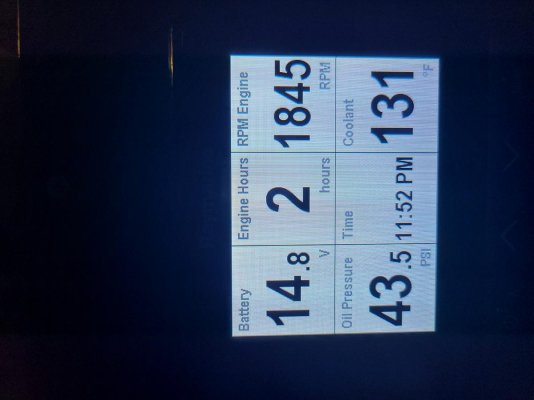

If you are wondering why my genset hours show as 2hrs in the attached picture, it is because this display doesn't show fractions for hours and because I replaced the controller on the genset 2.1 operating hours ago, at which time the indicated hours became 0. I did sticker the generator just above where it displays the hours with the offset as well as noted it in my operation and maintenance logs.

The genset had started acting weird, sometimes not starting or stopping from remote, sometimes throwing random errors at start (and then running fine), and sometimes showing fewer operating hours than actual. A new controller seems to have cured these erratic behaviors.

This is just a note for anyone it may help.

The Kohler 6EOD generator (and likely any others from Kohler using the ADC 2100, among others) has a digital gauge kit that uses the standard CAN/J1939 interface.

I didn't want to pay ~$800-$900 for the Kohler digital gauge kit, which contains a single multi-purpose digital gauge, especially since I'd need two of then to have one at each helm. So, I ordered the Yacht Devices YDEG-04 to take the data from the J1939 interface and put it onto my NMEA2000 (ST-NG) bus where my chart plotters and Raymarine i70 and other instrument can show it, as can my OpenCPN instances.

I hooked CAN_H to pin 1 (yellow) and CAN_L to pin 2 (Green) and the cable shield to pin 9 of the genset's Customer Interface Connector (CIC).

That, by itself didn't work, so I added a 120-Ohm resistor across the CAN_H and CAN_L on the second and otherwise unused of the "Y" connectors on the YDEG-04, and magic happened.

A 120-Ohm terminating resistor is typical for each side of a CAN bus to dampen signal reflections on the wire. In this case, after poking for a bit at the wires coming from the controller, I think the current through the resistor somehow turns on the interface on the controller. I didn't see much until it was there.

I mention this because the instructions with the YDEG-04 were seemingly written with an underlying assumption that one is attaching to an existing and properly terminated CAN bus versus creating a new one connecting the YDEG-04 and the genset. As a result, they don't mention that resistor as part of the installation instructions.

If you are wondering why my genset hours show as 2hrs in the attached picture, it is because this display doesn't show fractions for hours and because I replaced the controller on the genset 2.1 operating hours ago, at which time the indicated hours became 0. I did sticker the generator just above where it displays the hours with the offset as well as noted it in my operation and maintenance logs.

The genset had started acting weird, sometimes not starting or stopping from remote, sometimes throwing random errors at start (and then running fine), and sometimes showing fewer operating hours than actual. A new controller seems to have cured these erratic behaviors.