garmstro55

Senior Member

I am feeling kinda stupid as I have not yet figured out how to change the water pump impellers on my 4LHA-STP 240 HP engines. I get down into the engine room every once in a while and stare at the engine but I can't figure out where to start. Maybe one of my TF Mainship buddies can tell me how to get going. (Doug?, RichG? Bueller?)

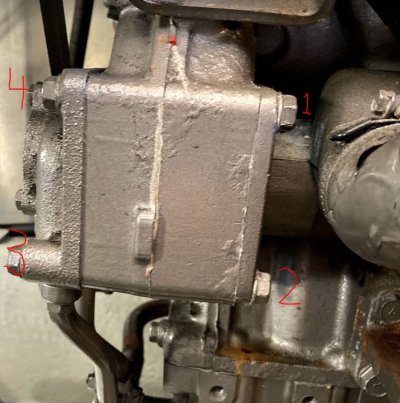

First picture: I think this is the pump. Do I remove bolts #1 and 2 and the other two you can't see on the backside? Or do I remove the bolts #3 and 4 and the two other on the front side?

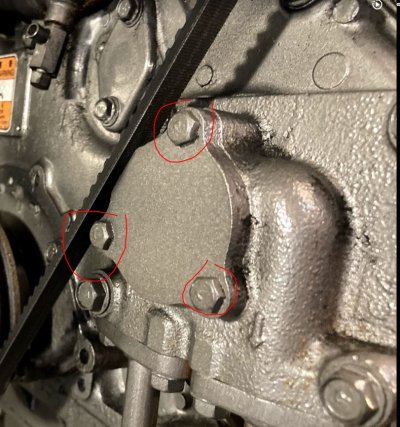

Or is the impeller behind the triangular shaped cap with the three bolts.

Or none of the above?

TIA

Gary

First picture: I think this is the pump. Do I remove bolts #1 and 2 and the other two you can't see on the backside? Or do I remove the bolts #3 and 4 and the two other on the front side?

Or is the impeller behind the triangular shaped cap with the three bolts.

Or none of the above?

TIA

Gary