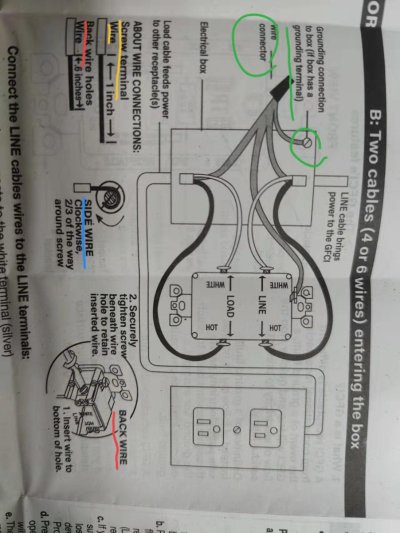

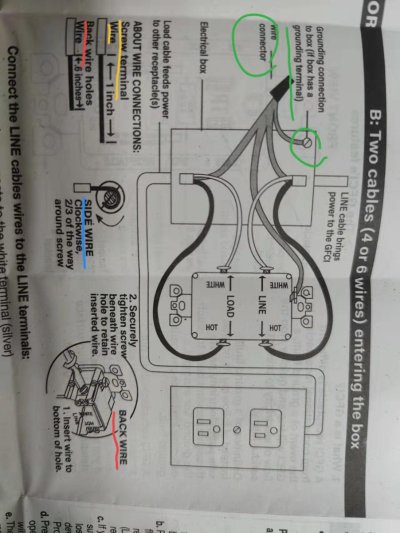

Backwiring requires solid core wire, which we don't have in boats. Basically, you strip the end of the wire the correct amount and then push the stripped end of the wire into one of those holes and an internal clamp sort of ratches onto it and holds it in place. It doesn't work with the stranded wire we have on boats. And, even in the applications for which it is designed and approved, most serious electricians and contractors will pinch their noses and turn away if it is mentioned. It is, in practice, a pretty poor way to make a connection. So, you most definitely don't want to backwire the outlet.

Some of these don't have internal clamps and, instead, the side-wire screw is screwed down to tighten up the back-wired wire. This still isn't as good as side-wiring, because the wire clamps a straight wire, rather than a loop of wire (see below)

In a non-boating application, side-wiring means striping the end of the wire the correct amount, twisting the stripped end around needle nose pliers in the direction screws tighten (clockwise), looping it over and then pulling it under the side screw terminal, and tightening down the screw to make a solid connection. It works very well with solid wire.

The unfortunate problem about almost every, if not every, GFCI outlet I've ever seen is that it isn't designed for marine stranded wire. Wrapping stranded wire under the screw terminal will result in it flattening out and making a poor connection, rather than being clamped as a solid wire does.

So, what to do? We can't use the back wiring, because it is for solid wire, and a bad idea, anyway, and we can't use the screw down terminal, because it doesn't work well with stranded wire, either?

There are a few things I've heard of people doing. Below are a few of them. I don't know if there is a best answer, or if there is, what it is:

1) One can crimp small ring connectors onto the end of the wire, back out the terminal screw entirely, place the screw through the connector, and then screw it back down. This isn't as easy or as correct as it might initially seem. The screws are designed not to be fully removed. The initial bit of thread is intentionally damaged to prevent them from easily coming out. They can be backed out, but they do might do a little damage to the threads within the outlet on the way, and getting them started again going back in can be a little trickier than normal.

And, there is another challenge. There is a often a little raised bit of plastic in front of the screw that is designed to help a loop of wire sit right. It usually forces the ring terminal to sit wrong. Some tolerate this. Some use a pair of needle nose pliers to break out this nub of plastic or cut it out with a sharp utility knife.

This is a "pick your poison approach" in two ways: (1) removing and reinstalling the screws in an unauthorized modification of the device, and removing the plastic bit, if one chooses to do that, is also.

2) Some people don't want to remove the screws since, well, they aren't intended to come out. These folks often use fork terminal as one might use in other situations where one wants to use a ring terminal, but can't remove the screw. This works, but it doesn't allow for as resilient a connection as a ring terminal. And, remember that numb of plastic? Unless it is removed, it'll disturb the way the fork sits, maybe causing it to open wider, and become even less resilient. So, again, you've got to pick your poison a bit about your willingness to modify the outlet device in an unauthorized way or not.

3) Some people, for reasons I don't fully understand, take ring connectors and cut a narrow bit, sometimes V-shaped, out of the front of them to make them sort of like fork connectors. They claim that these fit better than a fork connector because the opening is smaller and the shape is round, not straight. Dunno. Insert the same discussion from about about modifying things and the plastic nub .

4) Some people do other things, such as tightly twist the stranded wire to make it more like solid wire and then use it. This doesn't work. It is still stranded wire. Some people do this, then bend it into the loop, and then solder the loop to make it solid, and then install it. This seems to work w.r.t. the screw terminal, but it leaves a weak point where the soldered wire ends and it becomes stranded again. The thin strands like to break there from vibration, etc. I won't criticize these approaches. But, I wouldn't think of either.

Blue Sea Systems, Marinco, and Hubbell all sell what I've seen advertised as marine-rated GFCI outlets. But, they've all been configured in this respect just like the land units.

As for the wiring, the AC (not DC) black wire should go to the screw behind the smaller slot. The AC white wire should go to the screw behind the larger of the slots. And the AC green wire should go to the grounding conductor screw, which is usually a green screw attached to the metal frame.

This is all assuming the boat is wired conventionally. You've got to test and verify that yourself with a meter, etc. Check to make sure hot is hot, neutral is neutral, the grounding conductor is the grounding conductor, etc. Also, work with the breaker off and verify that there is nothing hot near what you are working on, perhaps with a glowing indicator device. Assume nothing.

All of this is just conversation is about a hypothetical install that is ephemeral in my mind. It isn't about your boat. If you work on your boat, you've got to safely get it right given whatever conditions you have, safely rectifying whatever deficiencies may exist to enable you to do that. Etc. Etc. Etc.