boomerang

Guru

- Joined

- Apr 29, 2016

- Messages

- 1,446

- Location

- united states

- Vessel Name

- Wandering Star

- Vessel Make

- Hatteras 42 LRC

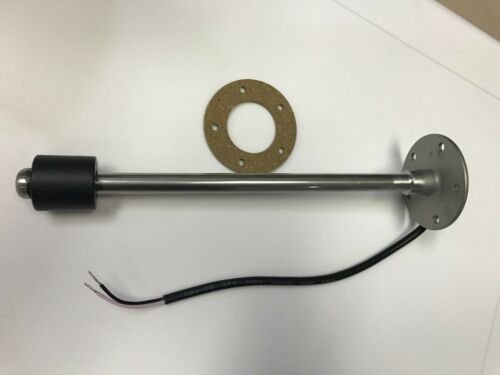

Right after we bought our boat in '16 ,both of the fuel gauges quit registering their respective levels within 12 months of each other. We've made do by dipping the tanks with a marked stick that the PO had onboard but a quick visual of the gauge is so much easier rather than sticking the tank so today is the day to tackle the project.

I long ago verified that it was the senders that were the culprit and not the wiring or the gauge so I pulled the carpet back, measured and cut a 4" access hole above each sending unit. There's only a couple of inches of clearance above the tanks and while it might've been possible to remove them without an access hole, it wasn't a big deal to cut them.

I pulled the first one out and saw the problem right away. Half of the float was gone and in the bottom of the tank. My first thought was "Oh crap! There must be water in the tank to have eaten up the metal float like this". I fished all around through the hole with a magnet but couldn't pull up any pieces. Then I saw that only the end of the float was fabricated from magnetic metal; the rest of the bulb was thin copper or brass. It wasn't corroded but it simply disintegrated. Weird. I can't imagine what caused it. I peered through the hole with a bright light but didn't see any pieces. The bottom was clean bright aluminum just like a new tank so I felt a little relieved and I'll just have to hope that the pieces stay in between the tank baffles and not decide to get lodged in the pickup tube aft.

I then pulled the other side and found the float bulb still intact but completely fuel of fuel.

So begins my quest for 2 new sending units.

I was able to see the number 8410 on one of the units but there seems to be another character after the "0" but maybe not. It's hard to tell. I searched 8410 fuel sending units but apparently 8410 is a John Deere tractor model number because that's what most of my hits have yielded.

I see plenty of senders but I'm not sure if all of them are the same ohm value as these and if the fastener indexing is the same size & pattern. I'll keep searching but if anyone has any insight on a replacement for these, it would be appreciated.

I long ago verified that it was the senders that were the culprit and not the wiring or the gauge so I pulled the carpet back, measured and cut a 4" access hole above each sending unit. There's only a couple of inches of clearance above the tanks and while it might've been possible to remove them without an access hole, it wasn't a big deal to cut them.

I pulled the first one out and saw the problem right away. Half of the float was gone and in the bottom of the tank. My first thought was "Oh crap! There must be water in the tank to have eaten up the metal float like this". I fished all around through the hole with a magnet but couldn't pull up any pieces. Then I saw that only the end of the float was fabricated from magnetic metal; the rest of the bulb was thin copper or brass. It wasn't corroded but it simply disintegrated. Weird. I can't imagine what caused it. I peered through the hole with a bright light but didn't see any pieces. The bottom was clean bright aluminum just like a new tank so I felt a little relieved and I'll just have to hope that the pieces stay in between the tank baffles and not decide to get lodged in the pickup tube aft.

I then pulled the other side and found the float bulb still intact but completely fuel of fuel.

So begins my quest for 2 new sending units.

I was able to see the number 8410 on one of the units but there seems to be another character after the "0" but maybe not. It's hard to tell. I searched 8410 fuel sending units but apparently 8410 is a John Deere tractor model number because that's what most of my hits have yielded.

I see plenty of senders but I'm not sure if all of them are the same ohm value as these and if the fastener indexing is the same size & pattern. I'll keep searching but if anyone has any insight on a replacement for these, it would be appreciated.