Portage_Bay

Guru

- Joined

- Oct 19, 2015

- Messages

- 2,624

- Location

- United States

- Vessel Name

- Pacific Myst

- Vessel Make

- West Bay 4500

Before you climb up my backside about lack of maintenance, which I of course deserve, know that I come from a lifetime of keel coolers and dry exhaust. Yup, I know, I gotta get all the crud out. My mess and well as POs.

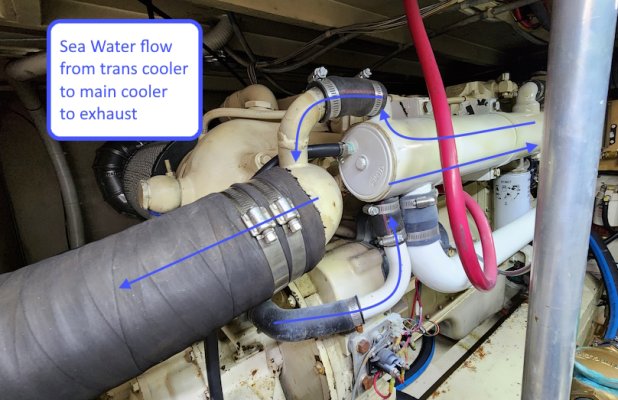

So, looking at the pics. Sendure on an older pair of Cummins 6BT. It looks like I can pull the end cap, clean out my mess as well as OP's messes. Fit a new gasket and it's all good.

I haven't shown pics of the tranny coolers. Cute little things. If I have to remove them, turn 'em on end and shake. Hoping that pulling the hose on the zinc fitting end will let me get in there with needle nose pliers and clean the mess out. I could see bits if impeller in there.

So, looking at the pics. Sendure on an older pair of Cummins 6BT. It looks like I can pull the end cap, clean out my mess as well as OP's messes. Fit a new gasket and it's all good.

I haven't shown pics of the tranny coolers. Cute little things. If I have to remove them, turn 'em on end and shake. Hoping that pulling the hose on the zinc fitting end will let me get in there with needle nose pliers and clean the mess out. I could see bits if impeller in there.