dvd

Senior Member

I bought this a year ago Spring with plans for full-time cruising starting this Summer. Spent all winter re-doing just about all the systems on board. Unfortunately, life sometimes gets in the way of boating and it is now for sale -- asking $85K/BO. This is a limited "Preview" offer, as I have talked with a broker and will likely move the boat to Annapolis and list it with him before the Power Boat Show in a couple of weeks. His price (surprise, surprise) is higher.

Thanks,

dvd

NEWBURYPORT 37

LOA • 37’ 0”

BEAM • 13’ 3”

DRAFT • 3’ 6”

GROSS TONS • 28T

WEIGHT • 19,800 lbs.

FUEL • 240 gal.

WATER • 180 gal.

HOLDING TANK • 40 gal.

VESSEL TYPE Single Engine Power Vessel – Semi-Displacement Design

BUILDER Her Shine Marine Co. Ltd., Kaohsiung - Taiwan, Designer: Ed Monk

MODEL NEWBURYPORT 37 – DOUBLE CABIN, YEAR BUILT 1987

H.I.N. MQN37803F687

Single skinned FRP construction (hand-laid) with simulated/molded planking. Stringers and bulkheads FRP tabbed to hull for increased rigidity.

Hullsides and quarters fitted with teak rub rails.

Hullside rub rails fitted with S/S guard.

Swim step of teak construction fastened to transom via S/S brackets.

Fitted with retractable S/Sboarding ladder.

Full skeg fitted with bronze lower heel bearing and S/S rudder.

Main Decks: Teak planking over FRP with plywood core. Planking secured via S/S fasteners.

10” bulwarks fitted with varnished teak toe rail.

Helm Deck/Aft Bridge Deck/Forward Cabin Top: White gelcoat with patterned non-skid over FRP with plywood core.

Main deck fitted with S/S stanchions/varnished teak cap rail fastened to toe rail.

Boarding gates port/starboard and aft.

(2) S/S hawse cleats forward, (2) S/S open-bodied midship cleats, and (2) open-bodied stern cleats.

Bulwarks fitted with S/S hawse feeds.

45 lb. Stainless Steel CQR design on stainless steel anchor roller

Lewmar Stainless Steel windlass with up/down pressure pad operation on foredeck and toggle operation at both helm stations.

Main engine shaft 2” S/S construction. Through-bolted flange design fitted with drive saver.

Sidepower SP75 bowthruster with dual (4) blade operation and joystick controls at both helm stations. Installed 12/ 2007.

(4) Aluminum saddle fuel tanks installed 2004 (60 gal each) - fitted with (2) external sight tubes (sight tubes fitted with valves).

Freshwater tanks stainless steel, 2 X 90 gal. with sight tube.

Holding tank, FRP 40 gal.

New “Smart” deck power fitting X 2.

Newmar 50-amp/three-stage/multi-bank battery charger.

Westerbeke 4.4 KW generator (Model W10B-2) about 900 hrs.

Balmar 100 Amp alternator on engine with remote three stage regulator.

Separate start batteries for both main engine and generator engine.

4 Group 27 105 Amp house batteries.

Engine - Perkins T6.544M 200 HP @ 2600 RPM with under 1000 hrs.

Borg-Warner velvet drive transmission model 10-14-000-005.

Racor 500 fuel filter for both main engine and generator engine fuel feeds.

Morse separate throttle/transmission levers at each station.

St. Croix S/S swivel/transom mount dinghy davits with 8:1 purchase block and tackle and S/S winches.

2 Sealand Vacuflush fresh water heads.

Zodiac Dinghy new 2007 (new valve stems 2011), 8 HP 2-cycle Evinrude outboard.

Maintenance/upgrades since 9/2011:

Mast and boom removed, stripped and painted, rewired, LED Anchor light and Running light installed.

Water heater element replaced.

Bottom sanded, repainted with ablative paint.

Underwater metal cleaned to bare, primed with 2-part primer, painted

Replaced 120V outlets with GFCIs.

Replaced main engine water pump impeller.

Repaired float switch for bilge pump, replaced wiring and hose clamps.

Installed access panel through forward head to service generator engine.

Replaced main engine shaft packing and hose clamps on stuffing box/shaft tunnel hose.

Replaced Racor fuel filters, disassembled and cleaned filter assemblies.

Moved generator control panel to overhead location.

Installed new AM/FM/CD radio and power amplified antenna.

Disassembled, cleaned and painted stereo speakers, reinstalled.

Replaced running light bulbs with LEDs.

Replaced grounding brush on main engine shaft

Disassembled, cleaned and repainted generator sound shield. Replaced soundproofing foam.

Replaced water pump impeller in generator engine.

Disassembled and cleaned generator heat exchanger, replaced zincs.

Removed lower helm controls, had them re-chromed, reinstalled.

New galley cabinetry installed with new 120V wiring and switch for new induction cooktop and new microwave/conduction oven.

All existing polybutylene plumbing was removed, all old plumbing fixtures removed.

Hot water heater and pressure pump moved to aft port position in engine room, rewired.

Added check valve, temperature compensating valve and pressure compensation tank to water system.

Replumbed all fixtures with PEX tubing (hot=red, cold=blue)

Replaced all plumbing fixtures in sinks, shower.

Sliding doors removed; exterior painted, interior varnished, reinstalled with HDPE runners.

Front opening window removed, stripped and disassembled, replaced cracked glass, exterior painted, interior varnished.

Teak trim strips fabricated for forward windows to allow runoff, windows caulked, painted.

Fore & aft Bowmar hatches removed, refurbished, reinstalled with butyl bedding tape.

New screens made for overhead hatches.

Flybridge “eyebrow” teak trim removed, bridge base filled and fiberglassed to cabin top, painted.

Flybridge instrument panel and frame removed, rebuilt, repainted and revarnished.

Electrical panels upgraded, separate 120V panel moved to forward passageway, added 2nd 30A service and 2nd “Smart” power fitting for future HVAC.

12V monitoring system installed.

All window screen frames removed, stripped, painted and new screen fabric installed.

Pull-out shelf installed under galley sink.

Refrigerator/freezer removed, new platform fabricated, replaced wiring to outlets, reinstalled refrigerator securely and added lower vent.

Replaced trim rings around 4 portlights with CNC-machined 1/4” Starboard, bedded in butyl tape.

Replaced old engine room floorboards with TREX lumber.

Fabricated and installed canvas tool holders in Engine Room

All interior cabin lighting updated with internal LED fixtures.

Teak decks refurbished with old caulking removed, joints cleaned, re-screwed boards as needed, caulked with TDS.

Swimstep delamination repaired, swimstep sanded and treated.

Installed new Standard Horizon VHF radio (with DSC) on bridge with remote at lower helm.

Bridge dashboard covering removed, holes filled/sanded, refinished with hammertone paint.

Naugahyde cover fabricated/installed for lower dashboard.

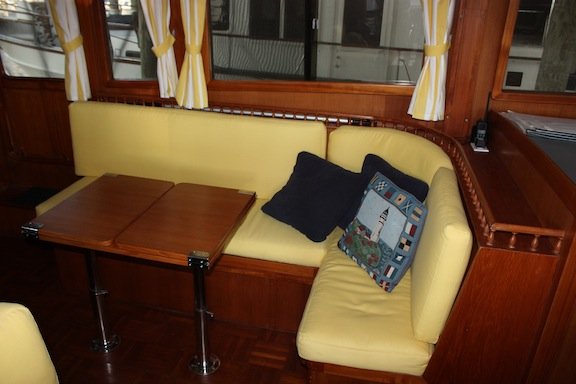

All interior cushions reupholstered.

New interior curtains fabricated/installed.

New Phifertex exterior window coverings for main cabin fabricated and installed.

All new electronics installed and networked:

SimRad - NSS8 (lower helm)

NSS7 (upper helm)

3G Broadband radar

AP24 autopilot with rudder feedback and hydraulic motor

AIS transceiver

Fluxgate compass

Depth finder

New VHF antenna

2 New GPS antennas

Thanks,

dvd

NEWBURYPORT 37

LOA • 37’ 0”

BEAM • 13’ 3”

DRAFT • 3’ 6”

GROSS TONS • 28T

WEIGHT • 19,800 lbs.

FUEL • 240 gal.

WATER • 180 gal.

HOLDING TANK • 40 gal.

VESSEL TYPE Single Engine Power Vessel – Semi-Displacement Design

BUILDER Her Shine Marine Co. Ltd., Kaohsiung - Taiwan, Designer: Ed Monk

MODEL NEWBURYPORT 37 – DOUBLE CABIN, YEAR BUILT 1987

H.I.N. MQN37803F687

Single skinned FRP construction (hand-laid) with simulated/molded planking. Stringers and bulkheads FRP tabbed to hull for increased rigidity.

Hullsides and quarters fitted with teak rub rails.

Hullside rub rails fitted with S/S guard.

Swim step of teak construction fastened to transom via S/S brackets.

Fitted with retractable S/Sboarding ladder.

Full skeg fitted with bronze lower heel bearing and S/S rudder.

Main Decks: Teak planking over FRP with plywood core. Planking secured via S/S fasteners.

10” bulwarks fitted with varnished teak toe rail.

Helm Deck/Aft Bridge Deck/Forward Cabin Top: White gelcoat with patterned non-skid over FRP with plywood core.

Main deck fitted with S/S stanchions/varnished teak cap rail fastened to toe rail.

Boarding gates port/starboard and aft.

(2) S/S hawse cleats forward, (2) S/S open-bodied midship cleats, and (2) open-bodied stern cleats.

Bulwarks fitted with S/S hawse feeds.

45 lb. Stainless Steel CQR design on stainless steel anchor roller

Lewmar Stainless Steel windlass with up/down pressure pad operation on foredeck and toggle operation at both helm stations.

Main engine shaft 2” S/S construction. Through-bolted flange design fitted with drive saver.

Sidepower SP75 bowthruster with dual (4) blade operation and joystick controls at both helm stations. Installed 12/ 2007.

(4) Aluminum saddle fuel tanks installed 2004 (60 gal each) - fitted with (2) external sight tubes (sight tubes fitted with valves).

Freshwater tanks stainless steel, 2 X 90 gal. with sight tube.

Holding tank, FRP 40 gal.

New “Smart” deck power fitting X 2.

Newmar 50-amp/three-stage/multi-bank battery charger.

Westerbeke 4.4 KW generator (Model W10B-2) about 900 hrs.

Balmar 100 Amp alternator on engine with remote three stage regulator.

Separate start batteries for both main engine and generator engine.

4 Group 27 105 Amp house batteries.

Engine - Perkins T6.544M 200 HP @ 2600 RPM with under 1000 hrs.

Borg-Warner velvet drive transmission model 10-14-000-005.

Racor 500 fuel filter for both main engine and generator engine fuel feeds.

Morse separate throttle/transmission levers at each station.

St. Croix S/S swivel/transom mount dinghy davits with 8:1 purchase block and tackle and S/S winches.

2 Sealand Vacuflush fresh water heads.

Zodiac Dinghy new 2007 (new valve stems 2011), 8 HP 2-cycle Evinrude outboard.

Maintenance/upgrades since 9/2011:

Mast and boom removed, stripped and painted, rewired, LED Anchor light and Running light installed.

Water heater element replaced.

Bottom sanded, repainted with ablative paint.

Underwater metal cleaned to bare, primed with 2-part primer, painted

Replaced 120V outlets with GFCIs.

Replaced main engine water pump impeller.

Repaired float switch for bilge pump, replaced wiring and hose clamps.

Installed access panel through forward head to service generator engine.

Replaced main engine shaft packing and hose clamps on stuffing box/shaft tunnel hose.

Replaced Racor fuel filters, disassembled and cleaned filter assemblies.

Moved generator control panel to overhead location.

Installed new AM/FM/CD radio and power amplified antenna.

Disassembled, cleaned and painted stereo speakers, reinstalled.

Replaced running light bulbs with LEDs.

Replaced grounding brush on main engine shaft

Disassembled, cleaned and repainted generator sound shield. Replaced soundproofing foam.

Replaced water pump impeller in generator engine.

Disassembled and cleaned generator heat exchanger, replaced zincs.

Removed lower helm controls, had them re-chromed, reinstalled.

New galley cabinetry installed with new 120V wiring and switch for new induction cooktop and new microwave/conduction oven.

All existing polybutylene plumbing was removed, all old plumbing fixtures removed.

Hot water heater and pressure pump moved to aft port position in engine room, rewired.

Added check valve, temperature compensating valve and pressure compensation tank to water system.

Replumbed all fixtures with PEX tubing (hot=red, cold=blue)

Replaced all plumbing fixtures in sinks, shower.

Sliding doors removed; exterior painted, interior varnished, reinstalled with HDPE runners.

Front opening window removed, stripped and disassembled, replaced cracked glass, exterior painted, interior varnished.

Teak trim strips fabricated for forward windows to allow runoff, windows caulked, painted.

Fore & aft Bowmar hatches removed, refurbished, reinstalled with butyl bedding tape.

New screens made for overhead hatches.

Flybridge “eyebrow” teak trim removed, bridge base filled and fiberglassed to cabin top, painted.

Flybridge instrument panel and frame removed, rebuilt, repainted and revarnished.

Electrical panels upgraded, separate 120V panel moved to forward passageway, added 2nd 30A service and 2nd “Smart” power fitting for future HVAC.

12V monitoring system installed.

All window screen frames removed, stripped, painted and new screen fabric installed.

Pull-out shelf installed under galley sink.

Refrigerator/freezer removed, new platform fabricated, replaced wiring to outlets, reinstalled refrigerator securely and added lower vent.

Replaced trim rings around 4 portlights with CNC-machined 1/4” Starboard, bedded in butyl tape.

Replaced old engine room floorboards with TREX lumber.

Fabricated and installed canvas tool holders in Engine Room

All interior cabin lighting updated with internal LED fixtures.

Teak decks refurbished with old caulking removed, joints cleaned, re-screwed boards as needed, caulked with TDS.

Swimstep delamination repaired, swimstep sanded and treated.

Installed new Standard Horizon VHF radio (with DSC) on bridge with remote at lower helm.

Bridge dashboard covering removed, holes filled/sanded, refinished with hammertone paint.

Naugahyde cover fabricated/installed for lower dashboard.

All interior cushions reupholstered.

New interior curtains fabricated/installed.

New Phifertex exterior window coverings for main cabin fabricated and installed.

All new electronics installed and networked:

SimRad - NSS8 (lower helm)

NSS7 (upper helm)

3G Broadband radar

AP24 autopilot with rudder feedback and hydraulic motor

AIS transceiver

Fluxgate compass

Depth finder

New VHF antenna

2 New GPS antennas

Attachments

-

Aft Cabin Stbd.jpg60.8 KB · Views: 237

Aft Cabin Stbd.jpg60.8 KB · Views: 237 -

Aft Head.jpg92.8 KB · Views: 243

Aft Head.jpg92.8 KB · Views: 243 -

Dinette.jpg64.2 KB · Views: 247

Dinette.jpg64.2 KB · Views: 247 -

Galley.jpg79.4 KB · Views: 238

Galley.jpg79.4 KB · Views: 238 -

Lower Helm.jpg84.6 KB · Views: 257

Lower Helm.jpg84.6 KB · Views: 257 -

ER Aft.jpg76.8 KB · Views: 253

ER Aft.jpg76.8 KB · Views: 253 -

Generator.jpg65.5 KB · Views: 257

Generator.jpg65.5 KB · Views: 257 -

ER.jpg80.2 KB · Views: 250

ER.jpg80.2 KB · Views: 250 -

Forward Cabin.jpg45.2 KB · Views: 262

Forward Cabin.jpg45.2 KB · Views: 262 -

Stbd View.jpg82.6 KB · Views: 287

Stbd View.jpg82.6 KB · Views: 287