Capstan

Senior Member

In February this year we purchased a Gulf Star 1973 Trawler, Hull # 59 for well under $10,000. after we discussed the pro's and cons we decided it was just too cheap to say no and the Admiral gave her OK. (The Admiral was surprised by the head room inside the vessel, that was the winner). Of course we knew it was a project boat but felt we had enough spare time after work and on the weekends to make us comfortable taking on a such a project.

We ran the engines for 10 minutes before taking oil samples of both mains and the Stbd result was very, very poor. However with the boat being moored only 4 miles away we took possession and not wanting to run the engines until we did some investigating we towed her across the “Wide Opening” to her new home.

Having access to tools, dockage and storage is a must to undertake a project like this. As we all know, these cost a lot over a period of time and need to be carefully considered when contemplating a rebirth for a new family member. Having all three at our disposal, I was sure, and still am, that we would keep that hole in the ocean fairly small with a reasonable/acceptable outpouring of coin.

Our backgrounds help as well: Earlier on in my career I spent 6 years engineering. I hold a valid 3,000 ton Master license and in 98-99 cruised 10,000 miles throughout the Pacific on my own sailboat before meeting my wife. I can honestly say the purchase decision weighed heavily upon my mind for the following reasons: “Can we stay focused? Do we have the skills? Do I really have an understanding of what this will cost? Will it become a burden and then a cause of tension between us?

Up until two weeks ago some of these questions were still unanswered.

I had thought about this purchase for over 3 years. Since we arrived at our job, nearly 6 years ago, The vessel had been swinging on a mooring 4 miles away. It took 3 years to finally ask if we could see her, and, if our friend the Park Warden, was contemplating selling her.

As they say “Timing is everything.”

Some pictures attached and below my work list we set and complete. The following are jobs completed in the 3 weeks of February. Next week I will post March and pictures if there is interest, and so on.

I will answer any questions I can on the little journey of our “Bad Monkey”.

“Up Ya Kilt”

Capstan

PS please let me know if this is in the wrong Thread/forum?

Weekly work list

Week 1

9th Feb Tow boat to marina

Remove all from interior and exterior hatches

20 hours to unload. That does not include sorting!

Vessel now sits 7.5" higher in the water!

Week 2

Start SS polishing of removed pieces

Replace oil coolers with new found in stern of boat.

Sort engineering spares

Remove heat exchangers

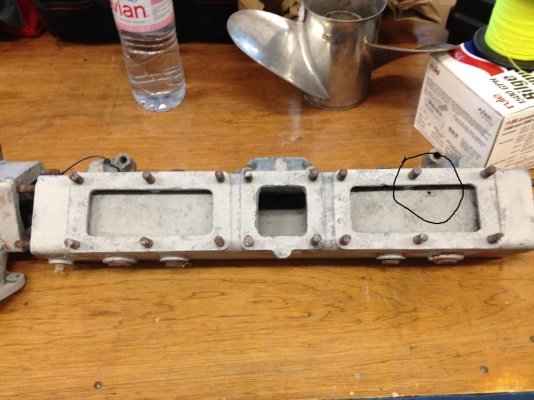

Remove exhaust manifolds and mixers

Week 3

Lemons and French friends and Godchildren.

Continue SS polishing

Remove snap fittings around windows and fill holes, sand

Jump off boat every day with the kids!

Week 4

Remove all stanchions, bases and railings Polish all Make a list of all.

Polish fuel in tank then remove

Send bases and fittings for quote for refinishing

45 pieces = $2,900. No thank you!

Drawing of hand rails to Andre

Remove fwd ss rub rails, polish

Move all ss to omh for storage

We ran the engines for 10 minutes before taking oil samples of both mains and the Stbd result was very, very poor. However with the boat being moored only 4 miles away we took possession and not wanting to run the engines until we did some investigating we towed her across the “Wide Opening” to her new home.

Having access to tools, dockage and storage is a must to undertake a project like this. As we all know, these cost a lot over a period of time and need to be carefully considered when contemplating a rebirth for a new family member. Having all three at our disposal, I was sure, and still am, that we would keep that hole in the ocean fairly small with a reasonable/acceptable outpouring of coin.

Our backgrounds help as well: Earlier on in my career I spent 6 years engineering. I hold a valid 3,000 ton Master license and in 98-99 cruised 10,000 miles throughout the Pacific on my own sailboat before meeting my wife. I can honestly say the purchase decision weighed heavily upon my mind for the following reasons: “Can we stay focused? Do we have the skills? Do I really have an understanding of what this will cost? Will it become a burden and then a cause of tension between us?

Up until two weeks ago some of these questions were still unanswered.

I had thought about this purchase for over 3 years. Since we arrived at our job, nearly 6 years ago, The vessel had been swinging on a mooring 4 miles away. It took 3 years to finally ask if we could see her, and, if our friend the Park Warden, was contemplating selling her.

As they say “Timing is everything.”

Some pictures attached and below my work list we set and complete. The following are jobs completed in the 3 weeks of February. Next week I will post March and pictures if there is interest, and so on.

I will answer any questions I can on the little journey of our “Bad Monkey”.

“Up Ya Kilt”

Capstan

PS please let me know if this is in the wrong Thread/forum?

Weekly work list

Week 1

9th Feb Tow boat to marina

Remove all from interior and exterior hatches

20 hours to unload. That does not include sorting!

Vessel now sits 7.5" higher in the water!

Week 2

Start SS polishing of removed pieces

Replace oil coolers with new found in stern of boat.

Sort engineering spares

Remove heat exchangers

Remove exhaust manifolds and mixers

Week 3

Lemons and French friends and Godchildren.

Continue SS polishing

Remove snap fittings around windows and fill holes, sand

Jump off boat every day with the kids!

Week 4

Remove all stanchions, bases and railings Polish all Make a list of all.

Polish fuel in tank then remove

Send bases and fittings for quote for refinishing

45 pieces = $2,900. No thank you!

Drawing of hand rails to Andre

Remove fwd ss rub rails, polish

Move all ss to omh for storage

Attachments

Last edited: