HeadedToTexas

Guru

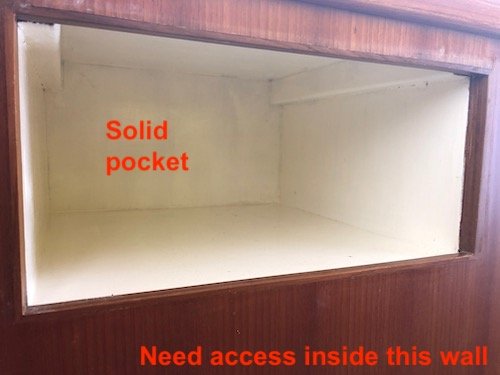

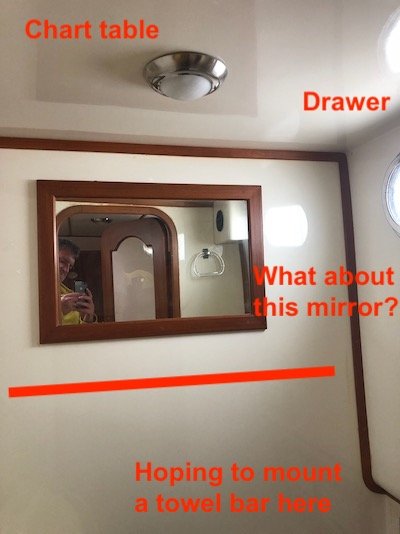

Is there a trick to accessing the back side of the aft wall of the forward head on the Helmsman 38/Mariner 37? I am planning to install a grab rail towel bar and need access to the back side to tighten the nuts.

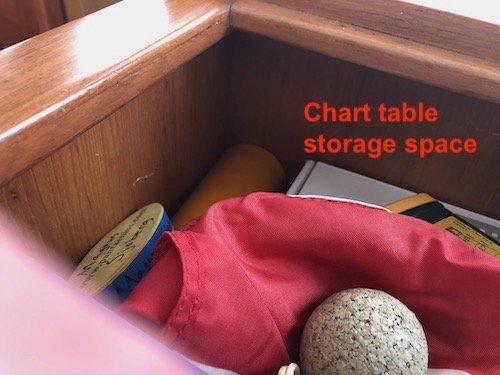

There may be space between the aft wall of the head and the forward knee area in the pilothouse, or there may be access beneath the "floor" of the chart "drawer" on the port side of the pilothouse. Sure would love to know before getting too aggressive with that beautiful wood.

There may be space between the aft wall of the head and the forward knee area in the pilothouse, or there may be access beneath the "floor" of the chart "drawer" on the port side of the pilothouse. Sure would love to know before getting too aggressive with that beautiful wood.