Cold Shot

Veteran Member

- Joined

- Feb 27, 2019

- Messages

- 26

- Location

- U.S.A

- Vessel Name

- Cold Shot

- Vessel Make

- 1997 38' Luhrs Tournament Open

Diesel Fuel Algae problem

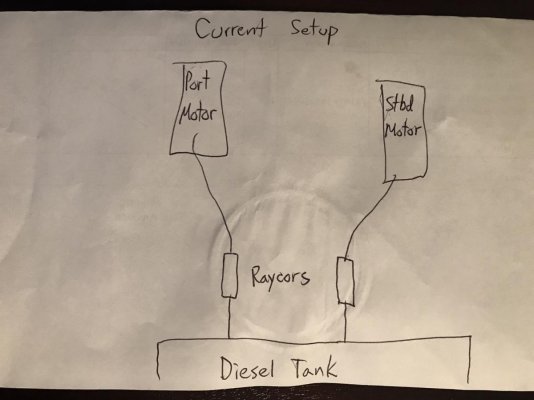

A few months ago I added a product in the 350 gallon main diesel tank called killem. It’s killed all the algae in the tank but now I have large pieces of it clogging the Racor filter. I’m looking to rig up an in-line screen filter that’s petroleum resistant that can filter out all the large trash so the Racors can do their jobs for the smaller particles. I drew diagrams of the current and new systems. The fuel intake and return hoses are 1/2”.

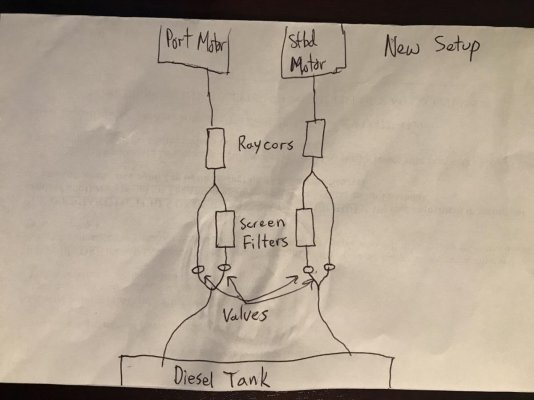

The new system will have all the fuel running into this screen filter. When running it will eventually clog up the screen and will restrict the fuel flow. At that time I can close the valve for the screen and open the one to the Racor. Then clean the screen out and reverse the valves again to start running. I found a brass fitting for it but I’m now looking for a large screen filter. Anyone have experience with this issue? Will a seawater strainer work? We had to be towed in from offshore Sunday ?

A few months ago I added a product in the 350 gallon main diesel tank called killem. It’s killed all the algae in the tank but now I have large pieces of it clogging the Racor filter. I’m looking to rig up an in-line screen filter that’s petroleum resistant that can filter out all the large trash so the Racors can do their jobs for the smaller particles. I drew diagrams of the current and new systems. The fuel intake and return hoses are 1/2”.

The new system will have all the fuel running into this screen filter. When running it will eventually clog up the screen and will restrict the fuel flow. At that time I can close the valve for the screen and open the one to the Racor. Then clean the screen out and reverse the valves again to start running. I found a brass fitting for it but I’m now looking for a large screen filter. Anyone have experience with this issue? Will a seawater strainer work? We had to be towed in from offshore Sunday ?