Essobee33034

Member

- Joined

- Oct 2, 2022

- Messages

- 5

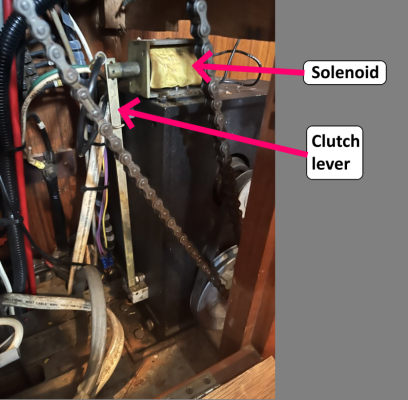

Good morning! We have a Grand Banks 36 Classic that we are thoroughly enjoying. She's not perfect but it has been fun getting to know her. One of the bits that we have broken is the autopilot. It is a simrad robertson AP11 heads with what I believe to be the J3000 box. The drive itself is a mechanical drive mounted below the lower helm. When it was working there was a noticeable thump when you engaged the autopilot, as if a mechanical clutch was engaging. This is no longer occurring, and within a minute of asking the unit to steer, one gets an error message on the display "actuator fail".

The unit worked fine for our purposes prior to breaking, so fixing the current one is preferred to replacement. I have found the manuals for the head unit and the installation guide but cannot identify the type of mechanical drive this is. Anybody have any ideas on a troubleshooting guide for the mechanical drive seen in the pictures? It has no label or identifying numbers and may just be a custom metal box for a reversing electric motor.

The unit worked fine for our purposes prior to breaking, so fixing the current one is preferred to replacement. I have found the manuals for the head unit and the installation guide but cannot identify the type of mechanical drive this is. Anybody have any ideas on a troubleshooting guide for the mechanical drive seen in the pictures? It has no label or identifying numbers and may just be a custom metal box for a reversing electric motor.