kwmeyer13

Senior Member

- Joined

- Oct 30, 2014

- Messages

- 260

- Location

- USA

- Vessel Name

- Guns 'N' Hoses II

- Vessel Make

- 2004 34' Pilothouse Sedan

Morning all,

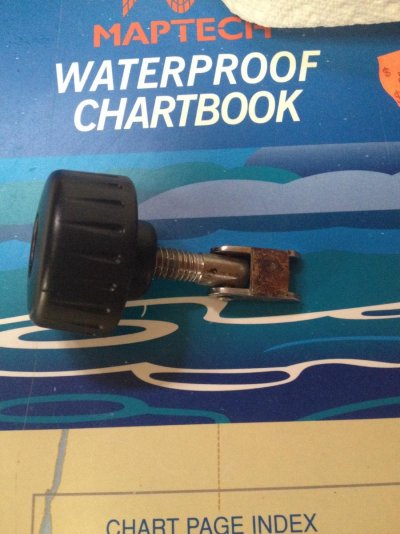

I have an issue with a few of my bomar portlights. It seems that the tack or spot weld that holds the knob which tightens down the hatch has come undone. I attached a a picture of the portlight. Has anyone had this issue? If so how did you go about fixing it? Did you take the portlight out and have it re-welded or did you replace the portlight altogether? Also has anyone replaced the portlight gasket?

Thanks,

Kevin

I have an issue with a few of my bomar portlights. It seems that the tack or spot weld that holds the knob which tightens down the hatch has come undone. I attached a a picture of the portlight. Has anyone had this issue? If so how did you go about fixing it? Did you take the portlight out and have it re-welded or did you replace the portlight altogether? Also has anyone replaced the portlight gasket?

Thanks,

Kevin