You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Breakers

- Thread starter Lou_tribal

- Start date

The friendliest place on the web for anyone who enjoys boating.

If you have answers, please help by responding to the unanswered posts.

If you have answers, please help by responding to the unanswered posts.

Lou_tribal

Guru

Contacts, springs and a heating coil. Are you figuring on designing and building your own circuit breakers?

The wheel was invented long ago and its unlikely that you can make a significant improvement with the resources available to you.

Marine circuit breakers, panels, etc. are readily available in many configurations. Compared to trying to build something yourself, they are inexpensive and they already carry approval from the necessary testing agencies. There is no real advantage to using anything different or "custom".

A future potential buyer will be much more comfortable with a "normal", brand name marine electrical system.

I am not sure to understand what you are talking about.

I do not plan to invent anything I just want to understand what is the difference between Marine breakers and DIN rail mount breaker, if there is any, nothing else.

Thank to tinped who sent me some documentation about DIN mount breakers yesterday evening it was very interesting to read.

L.

To my way of thinking, marine panels just "fit" more easily in most small boats, where space is tight. You can install matching 12VDC and 120VAC panels. Marine breakers all have screw terminals on both sides, or you can run a bus bar up one side. Without quoting any codes, my sense is that you want ring terminals on the wires, not compression screws found in home boxes. And as has already been mentioned, lots of different options off the shelf to customize for things not found in normal house installations. Presumably, they're built to withstand vibration and shock loading your house would never see.

If none of that is an issue for you, no doubt the home breakers will function fine.

If none of that is an issue for you, no doubt the home breakers will function fine.

Actually what Mr Lou-tribal would like to use is a mini breaker in the same configuration as you just mentioned. Vibration is definitely not an issue with this setup, as they are commonly used inside the enclosure of vibrating equipment such as commercial hvac systems. In all my years servicing industrial equipment, I have never seen one fail. I do agree that the options of adding bells, and whistles might be more difficult. I am still hoping Mr WesK chimes in about any issues, or concerns that abyc might have.

Lou_tribal

Guru

Indeed Mr Tinped pinpointed why I asked my question.

My bad I think I wrongly formulated my question by mentionning house breaker. In fact DIN rail breaker are often used in house in Europe but here in North America it is more common in industry so I should have mentionned industrial breakers.

The fact is that I find DIN rail based distribution panel very clean and easy to use and maintain as well as very compact so my interest. As an example the picture below is more or less showing what I mean:

Also what I find nice with DIN rail is that you can have a whole bunch of things not just breakers, like bus, relay, timers, energy meters, and terminal blocks, fused protected or not, all of this in nice clean IP65+ box.

As an example of something clean:

Hope this will clarify my question and show I do not want to customize something clunky homemade

L.

My bad I think I wrongly formulated my question by mentionning house breaker. In fact DIN rail breaker are often used in house in Europe but here in North America it is more common in industry so I should have mentionned industrial breakers.

The fact is that I find DIN rail based distribution panel very clean and easy to use and maintain as well as very compact so my interest. As an example the picture below is more or less showing what I mean:

Also what I find nice with DIN rail is that you can have a whole bunch of things not just breakers, like bus, relay, timers, energy meters, and terminal blocks, fused protected or not, all of this in nice clean IP65+ box.

As an example of something clean:

Hope this will clarify my question and show I do not want to customize something clunky homemade

L.

Ski in NC

Technical Guru

Looks good. Those screw clamp terminals will make wiring a breeze. Easier than dealing with crimp ring eyes and loose screws.

Seen something similar on some Euro boats. Not sure if you can get something similar for DC, but I think you can.

Seen something similar on some Euro boats. Not sure if you can get something similar for DC, but I think you can.

Lou_tribal

Guru

Looks good. Those screw clamp terminals will make wiring a breeze. Easier than dealing with crimp ring eyes and loose screws.

Seen something similar on some Euro boats. Not sure if you can get something similar for DC, but I think you can.

Yes these are existing for AC as well as DC. The terminal block are very nice too, especially the one that are fuse protected. They use automotive fuse inserted in the middle of the terminal block for each connector, very practical.

On a side note I continued my homework and read some docs and I noticed 2 things:

1. ABYC states that for AC the breakers must be matching UL489 or UL1077. However what they don't mention (and I think they should mention it) is that UL489 can be used in place of UL1077 but UL1077 must not be used in place of UL489.

2. ABYC states that DC breaker must be ignition protected but only if they are installed where are fumes that may ignite (which makes sense of course).

I did not notice anywhere that the breaker must meet UL489 Supplement SA/SB which is the Marine/Naval supplement to the UL489. Moreover it looks like (but I may be wrong) UL489 SUpplement SA applies only to vessels of 65 feet or more.

Now looking at structural difference between UL489 and UL489 Supplement SA the difference is mainly that for Supplement SA (so Marine listed) no aluminium or aluminium alloy is used for terminal connection, and breaker intended to be used in ER are calibrated at 50 degre C.

So from what I have found until now, there is nothing that prevent usage of industrial UL489 circuit breaker provided that:

1. It is not in ER

2. It is not in a place where fumes of any kind can ignite

3. There are put in a waterproof enclosure if used in a place where they can be water intrusion (like a boat).

If anybody have complementary information, it will be welcomed.

L.

Lou_tribal

Guru

I would want no aluminum in any part of the circuitry. I think that is what the code states??

Nope there is no explicit exclusion in ABYC 11E of usage of aluminium or I did not find it.

Regarding aluminium I understand that on the corrosion aspect it is not the most durable by far but if correctly maintained and setup in a IP65+ enclosure this should not be an issue. Am I missing something here?

Last edited:

Lou_tribal

Guru

Ok so basically this remove the difference I found between the marine and industrial breakers as thre is no alu. connector

READY2GO

Guru

- Joined

- Jan 3, 2012

- Messages

- 521

- Location

- USA

- Vessel Name

- Walkabout

- Vessel Make

- 1989 Sea Ray 380 Aft Cabin

Aluminum and copper have different rates of expansion, so the connections will eventually loosen. Aluminum wiring only existed for a short period in the late seventies, when there was a copper shortage. And yes, it is illegal.

I guess you are talking about small gauge wiring because using aluminum wire in residential and commercial applications is still the norm on larger size wires (above AWG10). Almost all wire ran by utility companies is aluminum.

RT Firefly

Enigma

Greetings,

Mr. R2G. From my poor memory, the problem with Al wire when it first came out is as Mr. t noted. Expansion coefficients. Al wire in a fixture designed for Cu wire posed a fire hazard. As the industry progressed, special fixtures that were compatible with Al became available and special installation instructions had to be followed. Corrosion was also a big factor with Al. I remember helping a friend, many years ago doing some wiring and we had to apply a non-corrosive paste to all connections.

Depending on application and geographical location I think it is still allowed but as noted, it is banned in other locales.

Mr. R2G. From my poor memory, the problem with Al wire when it first came out is as Mr. t noted. Expansion coefficients. Al wire in a fixture designed for Cu wire posed a fire hazard. As the industry progressed, special fixtures that were compatible with Al became available and special installation instructions had to be followed. Corrosion was also a big factor with Al. I remember helping a friend, many years ago doing some wiring and we had to apply a non-corrosive paste to all connections.

Depending on application and geographical location I think it is still allowed but as noted, it is banned in other locales.

Lou_tribal

Guru

Speaking about non corrosive past, as I started this thread I am allowed to hijack it, what about dielectric grease? For me it is a very good way to prevent contact corrosion. What, you fellow TFErs, areb thinking about it? Are you using it ot not? If not why?

Any comment will be a stone added to the knowledge building!

Any comment will be a stone added to the knowledge building!

I guess you are talking about small gauge wiring because using aluminum wire in residential and commercial applications is still the norm on larger size wires (above AWG10). Almost all wire ran by utility companies is aluminum.

Yes ,utility co's follow their own standards,and are not subject to NEC, or local building codes. Originally, back in the eighties, when we did meter pans, we would have to tail off the aluminum feeders from the power authority to copper using special compression connections that contained a paste that would mitigate the expansion issues.

Since around the mid nineties, a different alloy was used that no longer requires this paste. Not sure what they are made of.

GoneFarrell

Guru

Speaking about non corrosive past, as I started this thread I am allowed to hijack it, what about dielectric grease? For me it is a very good way to prevent contact corrosion. What, you fellow TFErs, areb thinking about it? Are you using it ot not? If not why?

Any comment will be a stone added to the knowledge building!

I use it where it seems appropriate, like when I put a new relay block for the winch in the upper part of the chain locker. I used some on the spade connectors that power the solenoids. But the main power connects of the large gauge wire I didn't use it, as they are robust connections with a lot of clamping force on the joint, and rubber hoods on the connections.

I don't use it on the main panel connects, no sweating there. But with my engine out back behind a V drive, I would use it there. Big swings in the relative humidity in there.

Time will tell if I'm right! Those connections will be on my spring checklist for sure. I made efforts last year to reduce moisture and condensation in lockers, that should help reduce a primary cause of corrosion.

what_barnacles

Guru

So if you dont want to pay the cost for a "marine" panel, design it yourself with these guys. They even supply a cad program for free.

https://www.frontpanelexpress.com/

https://www.frontpanelexpress.com/

jleonard

Guru

- Joined

- Jun 25, 2008

- Messages

- 5,176

Greetings,

Mr. R2G. From my poor memory, the problem with Al wire when it first came out is as Mr. t noted. Expansion coefficients. Al wire in a fixture designed for Cu wire posed a fire hazard. As the industry progressed, special fixtures that were compatible with Al became available and special installation instructions had to be followed. Corrosion was also a big factor with Al. I remember helping a friend, many years ago doing some wiring and we had to apply a non-corrosive paste to all connections.

Depending on application and geographical location I think it is still allowed but as noted, it is banned in other locales.

We just bought a house in Fl that was built in the 70s using Al branch wiring. The "fix" is to use "alumicon" connectors at each outlet. This was done prior to our buying the house to make it code compliant and insurable.

Also someone mentioned that they "thumped" a household breaker and it tripped. That is how they are supposed to work. I worked for a short time for a company that manufactures home circuit breakers (won't say which one) and that was one of the tests.

FF

Guru

- Joined

- Oct 12, 2007

- Messages

- 22,552

Modern aircraft use "arc fault breakers",

might be worth the effort to see if they can be had at the big box store.

might be worth the effort to see if they can be had at the big box store.

Datenight

Guru

Modern aircraft use "arc fault breakers",

might be worth the effort to see if they can be had at the big box store.

Not only available but required in bedrooms in Connecticut new construction.

Rob

Riverguy

Senior Member

- Joined

- Feb 17, 2013

- Messages

- 288

- Location

- USA

- Vessel Name

- Serendipitous

- Vessel Make

- Mainship 390, Bayliner 3258, Bayliner 4788

Old thread, critical topic! Danger of using residential (thermal) breakers in boats.

This is an old thread but misconceptions found throughout are potentially dangerous and need to be addressed.

The real answer to 'why not residential type breakers' has little or nothing to do with ignition protection. (although...if your shore-power breakers for SOME reason are installed in an engine compartment and the potential for explosive fumes exists, then you MUST use UL-1500 ignition protected marine breakers).

The real problem is more dangerous.

Residential breakers trip when an internal bi-metal strip reaches a certain temperature, the temperature rise being caused by current flowing through the bi-metal strip. It takes a bit of time for the metal to heat up (based on the mass of the bi-metal), so there is an 'engineered delay' such that these breakers don't trip instantaneously and so can handle the surge/start current required by (for example) an A/C or refrigerator compressor.

The problem is that these 'thermal' residential breakers are highly sensitive to ambient temperature. On a very hot day, a typical 15 amp breaker will trip at only 10 amps, but the same breaker will not trip until 25 amps on a very cold day. Making things worse, the majority of boats built with vastly cheaper residential breaker panels were also wired with vastly cheaper 'romex' (type-NM solid copper) residential wiring which presents a compounding problem; the insulation on that wire melts at a relatively low temperature; type NM romex has insulation that is only safe up to 60 degrees C, while UL-1426 "Boat Cable" insulation is rated for 105 C. Here in Minnesota (where I work on a lot of houseboats, mostly owned by year-round livaboards) there have been several 'winter fires' caused by the combination of residential thermal breakers and "romex'.

The scenario I've seen over and over again is this; in the summer, a houseboat owner arriving on board finds the temperature inside the boat is close to 100 degrees! The air-conditioning runs balls-to-the-wall for an hour or so, then trips the breaker (because the 15A breakers are tripping at 10 amps). The owner gets sick of his '15 amp' breakers tripping while trying to cool down the inside of the boat, so he/she replaces all the 15A residential breakers with 20A residential breakers. Then, in the wintertime (with electric space heaters, electric blankets, bilge heaters, bubblers, etc) those 20A breakers don't trip until close to 30A (!!!) -- and 30A is more than enough to drive the 14/2 Romex well beyond the safe temperature for it's insulation. The result is typically the very scary smell of burning electrical insulation and (more and more) a resulting fire.

So THAT is why residential thermal breakers should never be used on boats. The breakers used on 'real' boats are of the magnetic-hydraulic design, where the breaker trips based on the electro-magnetic field created by current running through a wire coil in the breaker -- and electromagnetism is totally independent of temperature. In these breakers, the delay required to handle surge/start currents is created by hydraulics (a bit like a shock absorber).

It's easy to understand the confusion and the misconception that ignition-protection is the only or main reason to use 'boat breakers' instead of residential breakers -- but this is a dangerous misconception.

As an aside, the vast majority of hydraulic-magnetic breakers I find in boat shore-power panels are not ignition-protected (and don't need to be) because these electrical panels are never installed in gasoline engine compartments.

So, you probably DON'T need ignition protected breakers in your shore-power panels, but that doesn't mean it's OK to use residential (thermal) breakers.

Hi TFers,

reading some threads one question came to my mind.

Why can we not use AC or DC breaker made for house aboard a boat?

I know that boat ones are ignition protected....

L.

This is an old thread but misconceptions found throughout are potentially dangerous and need to be addressed.

The real answer to 'why not residential type breakers' has little or nothing to do with ignition protection. (although...if your shore-power breakers for SOME reason are installed in an engine compartment and the potential for explosive fumes exists, then you MUST use UL-1500 ignition protected marine breakers).

The real problem is more dangerous.

Residential breakers trip when an internal bi-metal strip reaches a certain temperature, the temperature rise being caused by current flowing through the bi-metal strip. It takes a bit of time for the metal to heat up (based on the mass of the bi-metal), so there is an 'engineered delay' such that these breakers don't trip instantaneously and so can handle the surge/start current required by (for example) an A/C or refrigerator compressor.

The problem is that these 'thermal' residential breakers are highly sensitive to ambient temperature. On a very hot day, a typical 15 amp breaker will trip at only 10 amps, but the same breaker will not trip until 25 amps on a very cold day. Making things worse, the majority of boats built with vastly cheaper residential breaker panels were also wired with vastly cheaper 'romex' (type-NM solid copper) residential wiring which presents a compounding problem; the insulation on that wire melts at a relatively low temperature; type NM romex has insulation that is only safe up to 60 degrees C, while UL-1426 "Boat Cable" insulation is rated for 105 C. Here in Minnesota (where I work on a lot of houseboats, mostly owned by year-round livaboards) there have been several 'winter fires' caused by the combination of residential thermal breakers and "romex'.

The scenario I've seen over and over again is this; in the summer, a houseboat owner arriving on board finds the temperature inside the boat is close to 100 degrees! The air-conditioning runs balls-to-the-wall for an hour or so, then trips the breaker (because the 15A breakers are tripping at 10 amps). The owner gets sick of his '15 amp' breakers tripping while trying to cool down the inside of the boat, so he/she replaces all the 15A residential breakers with 20A residential breakers. Then, in the wintertime (with electric space heaters, electric blankets, bilge heaters, bubblers, etc) those 20A breakers don't trip until close to 30A (!!!) -- and 30A is more than enough to drive the 14/2 Romex well beyond the safe temperature for it's insulation. The result is typically the very scary smell of burning electrical insulation and (more and more) a resulting fire.

So THAT is why residential thermal breakers should never be used on boats. The breakers used on 'real' boats are of the magnetic-hydraulic design, where the breaker trips based on the electro-magnetic field created by current running through a wire coil in the breaker -- and electromagnetism is totally independent of temperature. In these breakers, the delay required to handle surge/start currents is created by hydraulics (a bit like a shock absorber).

It's easy to understand the confusion and the misconception that ignition-protection is the only or main reason to use 'boat breakers' instead of residential breakers -- but this is a dangerous misconception.

As an aside, the vast majority of hydraulic-magnetic breakers I find in boat shore-power panels are not ignition-protected (and don't need to be) because these electrical panels are never installed in gasoline engine compartments.

So, you probably DON'T need ignition protected breakers in your shore-power panels, but that doesn't mean it's OK to use residential (thermal) breakers.

Riverguy

Senior Member

- Joined

- Feb 17, 2013

- Messages

- 288

- Location

- USA

- Vessel Name

- Serendipitous

- Vessel Make

- Mainship 390, Bayliner 3258, Bayliner 4788

Here's an IEEE article for any engineers reading this...

https://ieeexplore.ieee.org/document/8669748

https://ieeexplore.ieee.org/document/8669748

mvweebles

Guru

- Joined

- Mar 21, 2019

- Messages

- 7,759

- Location

- United States

- Vessel Name

- Weebles

- Vessel Make

- 1970 Willard 36 Trawler

This is an old thread but misconceptions found throughout are potentially dangerous and need to be addressed.

The real answer to 'why not residential type breakers' has little or nothing to do with ignition protection. (although...if your shore-power breakers for SOME reason are installed in an engine compartment and the potential for explosive fumes exists, then you MUST use UL-1500 ignition protected marine breakers).

The real problem is more dangerous.

Residential breakers trip when an internal bi-metal strip reaches a certain temperature, the temperature rise being caused by current flowing through the bi-metal strip. It takes a bit of time for the metal to heat up (based on the mass of the bi-metal), so there is an 'engineered delay' such that these breakers don't trip instantaneously and so can handle the surge/start current required by (for example) an A/C or refrigerator compressor.

The problem is that these 'thermal' residential breakers are highly sensitive to ambient temperature. On a very hot day, a typical 15 amp breaker will trip at only 10 amps, but the same breaker will not trip until 25 amps on a very cold day. Making things worse, the majority of boats built with vastly cheaper residential breaker panels were also wired with vastly cheaper 'romex' (type-NM solid copper) residential wiring which presents a compounding problem; the insulation on that wire melts at a relatively low temperature; type NM romex has insulation that is only safe up to 60 degrees C, while UL-1426 "Boat Cable" insulation is rated for 105 C. Here in Minnesota (where I work on a lot of houseboats, mostly owned by year-round livaboards) there have been several 'winter fires' caused by the combination of residential thermal breakers and "romex'.

The scenario I've seen over and over again is this; in the summer, a houseboat owner arriving on board finds the temperature inside the boat is close to 100 degrees! The air-conditioning runs balls-to-the-wall for an hour or so, then trips the breaker (because the 15A breakers are tripping at 10 amps). The owner gets sick of his '15 amp' breakers tripping while trying to cool down the inside of the boat, so he/she replaces all the 15A residential breakers with 20A residential breakers. Then, in the wintertime (with electric space heaters, electric blankets, bilge heaters, bubblers, etc) those 20A breakers don't trip until close to 30A (!!!) -- and 30A is more than enough to drive the 14/2 Romex well beyond the safe temperature for it's insulation. The result is typically the very scary smell of burning electrical insulation and (more and more) a resulting fire.

So THAT is why residential thermal breakers should never be used on boats. The breakers used on 'real' boats are of the magnetic-hydraulic design, where the breaker trips based on the electro-magnetic field created by current running through a wire coil in the breaker -- and electromagnetism is totally independent of temperature. In these breakers, the delay required to handle surge/start currents is created by hydraulics (a bit like a shock absorber).

It's easy to understand the confusion and the misconception that ignition-protection is the only or main reason to use 'boat breakers' instead of residential breakers -- but this is a dangerous misconception.

As an aside, the vast majority of hydraulic-magnetic breakers I find in boat shore-power panels are not ignition-protected (and don't need to be) because these electrical panels are never installed in gasoline engine compartments.

So, you probably DON'T need ignition protected breakers in your shore-power panels, but that doesn't mean it's OK to use residential (thermal) breakers.

I read through this thread as a learning experience. Partway through, the OP clarified he was talking about DIN Rail breakers, not the standard Siemens/Square-D breakers so common at Home Depot. Also was not telling about solid core Romex but rather stranded copper.

Does your guidance hold for DIN rail breakers? While I wouldn't go that route on a yacht. I have to admit they are super easy and compact to use and install. I guess the question is are they thermal breakers as you suggest? Also, Blue Sea breakers are designed to provide both circuit protection and switching. Do standard US style breakers provide switching too? Do DIN Rail breakers? I have no idea.

Thoughts?

Peter

Cigatoo

Guru

- Joined

- Sep 9, 2016

- Messages

- 1,905

- Location

- Narragansett Bay

- Vessel Name

- Cigatoo

- Vessel Make

- Grand Banks 36 Classic #715

This is an old thread but misconceptions found throughout are potentially dangerous and need to be addressed.

The real answer to 'why not residential type breakers' has little or nothing to do with ignition protection. (although...if your shore-power breakers for SOME reason are installed in an engine compartment and the potential for explosive fumes exists, then you MUST use UL-1500 ignition protected marine breakers).

The real problem is more dangerous.

Residential breakers trip when an internal bi-metal strip reaches a certain temperature, the temperature rise being caused by current flowing through the bi-metal strip. It takes a bit of time for the metal to heat up (based on the mass of the bi-metal), so there is an 'engineered delay' such that these breakers don't trip instantaneously and so can handle the surge/start current required by (for example) an A/C or refrigerator compressor.

The problem is that these 'thermal' residential breakers are highly sensitive to ambient temperature. On a very hot day, a typical 15 amp breaker will trip at only 10 amps, but the same breaker will not trip until 25 amps on a very cold day. Making things worse, the majority of boats built with vastly cheaper residential breaker panels were also wired with vastly cheaper 'romex' (type-NM solid copper) residential wiring which presents a compounding problem; the insulation on that wire melts at a relatively low temperature; type NM romex has insulation that is only safe up to 60 degrees C, while UL-1426 "Boat Cable" insulation is rated for 105 C. Here in Minnesota (where I work on a lot of houseboats, mostly owned by year-round livaboards) there have been several 'winter fires' caused by the combination of residential thermal breakers and "romex'.

The scenario I've seen over and over again is this; in the summer, a houseboat owner arriving on board finds the temperature inside the boat is close to 100 degrees! The air-conditioning runs balls-to-the-wall for an hour or so, then trips the breaker (because the 15A breakers are tripping at 10 amps). The owner gets sick of his '15 amp' breakers tripping while trying to cool down the inside of the boat, so he/she replaces all the 15A residential breakers with 20A residential breakers. Then, in the wintertime (with electric space heaters, electric blankets, bilge heaters, bubblers, etc) those 20A breakers don't trip until close to 30A (!!!) -- and 30A is more than enough to drive the 14/2 Romex well beyond the safe temperature for it's insulation. The result is typically the very scary smell of burning electrical insulation and (more and more) a resulting fire.

So THAT is why residential thermal breakers should never be used on boats. The breakers used on 'real' boats are of the magnetic-hydraulic design, where the breaker trips based on the electro-magnetic field created by current running through a wire coil in the breaker -- and electromagnetism is totally independent of temperature. In these breakers, the delay required to handle surge/start currents is created by hydraulics (a bit like a shock absorber).

It's easy to understand the confusion and the misconception that ignition-protection is the only or main reason to use 'boat breakers' instead of residential breakers -- but this is a dangerous misconception.

As an aside, the vast majority of hydraulic-magnetic breakers I find in boat shore-power panels are not ignition-protected (and don't need to be) because these electrical panels are never installed in gasoline engine compartments.

So, you probably DON'T need ignition protected breakers in your shore-power panels, but that doesn't mean it's OK to use residential (thermal) breakers.

Very informative post! Thank you for your excellent explanation!

twistedtree

Guru

Here's an IEEE article for any engineers reading this...

https://ieeexplore.ieee.org/document/8669748

Thanks for this and your commentary. I'm far from an expert on breakers, but read about thermal breakers, thermal,magnetic breakers, and you mentioned hydraulic/magnetic breakers. I have no doubt they behave differently.

First, let me be clear that I am not advocating use of Romex cable, and certainly not advocating installing over-rated breakers. Both are clear violations of standards, and just a bad practice in a boat.

But I am less clear on the breaker requirements and characteristics. I'd have to check, but I think ABYC calls for UL489 or UL1077 for breakers. I'm familiar with E11 which addresses electrical systems in boats, and there is a separate standard that I'm not familiar with that addresses electrical component specs. But all I've seen in E11 is a call for breakers meeting one of the above UL standards, which would seem to include the offending breakers in the IEEE report.

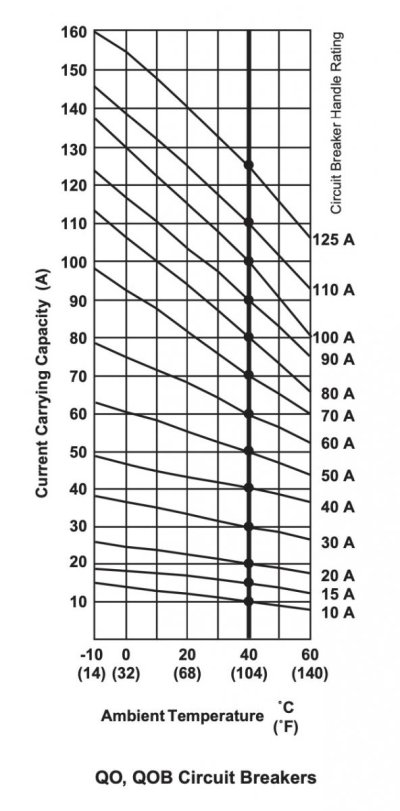

It's also unclear to me how common thermal breakers are vs thermal-magnetic breakers. I have used a lot of thermal-magnetic Square D QO breakers in land applications. I honestly never paid any attention to their trip curves, but this made me look. They don't exhibit the wide variation based on temperature described in the article. Not even close. Is this because they are thermal-magnetic, and not just thermal? I don't know.

Here are the trips points over temp for QO breakers, which are very common residential breakers. A 15A breaker trips at 15A at 40C. At -10C it does go up, but only to about 19A.

So it seems there is more to this than "residential" vs "marine". Terms like that get throw around all the time with no clear meaning.

Attachments

Lou_tribal

Guru

This is an old thread but misconceptions found throughout are potentially dangerous and need to be addressed.

The real answer to 'why not residential type breakers' has little or nothing to do with ignition protection. (although...if your shore-power breakers for SOME reason are installed in an engine compartment and the potential for explosive fumes exists, then you MUST use UL-1500 ignition protected marine breakers).

The real problem is more dangerous.

Residential breakers trip when an internal bi-metal strip reaches a certain temperature, the temperature rise being caused by current flowing through the bi-metal strip. It takes a bit of time for the metal to heat up (based on the mass of the bi-metal), so there is an 'engineered delay' such that these breakers don't trip instantaneously and so can handle the surge/start current required by (for example) an A/C or refrigerator compressor.

The problem is that these 'thermal' residential breakers are highly sensitive to ambient temperature. On a very hot day, a typical 15 amp breaker will trip at only 10 amps, but the same breaker will not trip until 25 amps on a very cold day. Making things worse, the majority of boats built with vastly cheaper residential breaker panels were also wired with vastly cheaper 'romex' (type-NM solid copper) residential wiring which presents a compounding problem; the insulation on that wire melts at a relatively low temperature; type NM romex has insulation that is only safe up to 60 degrees C, while UL-1426 "Boat Cable" insulation is rated for 105 C. Here in Minnesota (where I work on a lot of houseboats, mostly owned by year-round livaboards) there have been several 'winter fires' caused by the combination of residential thermal breakers and "romex'.

The scenario I've seen over and over again is this; in the summer, a houseboat owner arriving on board finds the temperature inside the boat is close to 100 degrees! The air-conditioning runs balls-to-the-wall for an hour or so, then trips the breaker (because the 15A breakers are tripping at 10 amps). The owner gets sick of his '15 amp' breakers tripping while trying to cool down the inside of the boat, so he/she replaces all the 15A residential breakers with 20A residential breakers. Then, in the wintertime (with electric space heaters, electric blankets, bilge heaters, bubblers, etc) those 20A breakers don't trip until close to 30A (!!!) -- and 30A is more than enough to drive the 14/2 Romex well beyond the safe temperature for it's insulation. The result is typically the very scary smell of burning electrical insulation and (more and more) a resulting fire.

So THAT is why residential thermal breakers should never be used on boats. The breakers used on 'real' boats are of the magnetic-hydraulic design, where the breaker trips based on the electro-magnetic field created by current running through a wire coil in the breaker -- and electromagnetism is totally independent of temperature. In these breakers, the delay required to handle surge/start currents is created by hydraulics (a bit like a shock absorber).

It's easy to understand the confusion and the misconception that ignition-protection is the only or main reason to use 'boat breakers' instead of residential breakers -- but this is a dangerous misconception.

As an aside, the vast majority of hydraulic-magnetic breakers I find in boat shore-power panels are not ignition-protected (and don't need to be) because these electrical panels are never installed in gasoline engine compartments.

So, you probably DON'T need ignition protected breakers in your shore-power panels, but that doesn't mean it's OK to use residential (thermal) breakers.

Interesting but you assume that residential breaker are all thermal which is wrong. Siemens among others is selling hydraulic magnetic breakers in DIN very compact format commonly used in house panels and conforming to the certification mentioned in E11.

My question was more about using DIN rail format because it makes a far more compact panel and DIN breaker housing of all sort, all size are available and they are basically cheaper that anything stamped "marine" while compliant to the exact same certifications. Also a lot of controllers are available in the same format if one wants to add a touch of automation aboard.

L

SteveK

Guru

- Joined

- Jul 5, 2019

- Messages

- 5,890

- Location

- Gulf Islands, BC Canada

- Vessel Name

- Sea Sanctuary

- Vessel Make

- Bayliner 4588

Lou you answered your own question, go ahead and test the upgrade. Or ask an ABYC electrician to explain why not.

Recently read where tinned wire was not actually necessary but a requirement of ABYC.

I only care if my insurer cares.

Recently read where tinned wire was not actually necessary but a requirement of ABYC.

I only care if my insurer cares.

Similar threads

- Replies

- 16

- Views

- 635

- Replies

- 28

- Views

- 1K

- Replies

- 26

- Views

- 2K

- Replies

- 4

- Views

- 780