You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

DD671’s TI’s fuel consumption

- Thread starter Bobupton

- Start date

The friendliest place on the web for anyone who enjoys boating.

If you have answers, please help by responding to the unanswered posts.

If you have answers, please help by responding to the unanswered posts.

Comodave

Moderator Emeritus

- Joined

- Jul 2, 2015

- Messages

- 22,513

- Location

- Au Gres, MI

- Vessel Name

- Black Dog

- Vessel Make

- Formula 41PC

Welcome aboard and congrats on your new boat.

Lepke

Guru

- Joined

- Jun 19, 2016

- Messages

- 3,136

- Location

- US

- Vessel Name

- Charlie Harper

- Vessel Make

- Wheeler Shipyard 83'

What I have on J&T and Detroit 671 TI:

600 hours are good depending on how they were run and maintained.

Well maintained engines get about 3000+ hours between rebuilds. Poorly cared for I've seen as low as 1000 hours. I have gone 10,000 hours, but I baby my engines and keep the oil clean. I have naturals now.

600 hours are good depending on how they were run and maintained.

Well maintained engines get about 3000+ hours between rebuilds. Poorly cared for I've seen as low as 1000 hours. I have gone 10,000 hours, but I baby my engines and keep the oil clean. I have naturals now.

Attachments

What I have on J&T and Detroit 671 TI:

600 hours are good depending on how they were run and maintained.

Well maintained engines get about 3000+ hours between rebuilds. Poorly cared for I've seen as low as 1000 hours. I have gone 10,000 hours, but I baby my engines and keep the oil clean. I have naturals now.

Nice to read a straight shot on what hours before rebuild actually can be the average on 671's.

Bobupton

Member

- Joined

- Dec 22, 2021

- Messages

- 9

- Vessel Name

- Joyful Spirit

- Vessel Make

- 47 Mainship Motoryacht

Thank you for the reply - Trying to confirm that we have J&T - didn’t see J&T on the front of blower, all I saw was Detroit Diesel metal tag - think they are J&T’sWhat I have on J&T and Detroit 671 TI:

600 hours are good depending on how they were run and maintained.

Well maintained engines get about 3000+ hours between rebuilds. Poorly cared for I've seen as low as 1000 hours. I have gone 10,000 hours, but I baby my engines and keep the oil clean. I have naturals now.

Engine overhead lights came yesterday

plan to baby my engines also

Lepke

Guru

- Joined

- Jun 19, 2016

- Messages

- 3,136

- Location

- US

- Vessel Name

- Charlie Harper

- Vessel Make

- Wheeler Shipyard 83'

Detroit Diesel got jealous of J&T and stopped selling them engines to make their own high HP engines. I don't remember when the changeover happened.

I use Shell Rotella T4 15w-40 I get at Walmart. My mains are 1947 engines that came with bypass filters. They've been overhauled once about 10 years ago. Most engines before 1950 used bypass filters and several still did in the 1950s. On later engines I always had a bypass filter besides the full flow filter until I went to using a centrifuge. I use the smallest micron spin on bypass filter or a hydraulic filter. Usually 1 or 2. You can't use a small micron in place of the full flow filter unless the engine oil system is very clean. And you better have an oil pressure alarm.

I get my filter elements usually from https://www.baldwinfilters.com

I buy by the case. Oil and fuel. Sometimes I buy on ebay. Almost any brand but Fram.

Even though I centrifuge my oil, I still run oil filters, they just don't get dirty. I batch clean the oil after a long run. Somewhere between 50-100 hours. My oil stays semi transparent. I test my oil yearly or about 500 hours. I take my oil sample before centrifuging. Otherwise it tests as new. The oil filters will catch some water and I always cut open spin on filters to see what was caught. There is a tool that makes cutting easy. They're about $40 on Amazon.

Because of the centrifuge, I haven't actually changed oil since 2011. It tests fine.

I try to run turbo engines at no more than 80% of total HP. In a sport fisher that means 25 instead of 30 knots. And a lot less fuel. I've owned several engines than never ran over 80% between overhauls. Turbos give much more power, but at the cost of metal wear. Boat builders like turbo engines because they can put a more powerful engine in a smaller space. Overhauling or replacing isn't their problem.

I use Shell Rotella T4 15w-40 I get at Walmart. My mains are 1947 engines that came with bypass filters. They've been overhauled once about 10 years ago. Most engines before 1950 used bypass filters and several still did in the 1950s. On later engines I always had a bypass filter besides the full flow filter until I went to using a centrifuge. I use the smallest micron spin on bypass filter or a hydraulic filter. Usually 1 or 2. You can't use a small micron in place of the full flow filter unless the engine oil system is very clean. And you better have an oil pressure alarm.

I get my filter elements usually from https://www.baldwinfilters.com

I buy by the case. Oil and fuel. Sometimes I buy on ebay. Almost any brand but Fram.

Even though I centrifuge my oil, I still run oil filters, they just don't get dirty. I batch clean the oil after a long run. Somewhere between 50-100 hours. My oil stays semi transparent. I test my oil yearly or about 500 hours. I take my oil sample before centrifuging. Otherwise it tests as new. The oil filters will catch some water and I always cut open spin on filters to see what was caught. There is a tool that makes cutting easy. They're about $40 on Amazon.

Because of the centrifuge, I haven't actually changed oil since 2011. It tests fine.

I try to run turbo engines at no more than 80% of total HP. In a sport fisher that means 25 instead of 30 knots. And a lot less fuel. I've owned several engines than never ran over 80% between overhauls. Turbos give much more power, but at the cost of metal wear. Boat builders like turbo engines because they can put a more powerful engine in a smaller space. Overhauling or replacing isn't their problem.

twistedtree

Guru

I'm really surprised to hear that the typical rebuild interval is 3,000 hrs. A modern diesel is more like 30,000 hrs. It seems to me that the old DD's don't run forever, but rather they can be rebuild forever.

Gdavid

Guru

I'm really surprised to hear that the typical rebuild interval is 3,000 hrs. A modern diesel is more like 30,000 hrs. It seems to me that the old DD's don't run forever, but rather they can be rebuild forever.

That is for the highest HP rating and engines run hard, the power they make depends on injector size as well as having turbos and intercoolers. For example: A 671 rated at 450 HP might be 3000 hours but a 410 HP might get closer to 5000 hours. The real challenge is weight, between their weight and the tankage a planning boat carries, they often need to be run hard to plane a boat.

On the other end of the spectrum, a 671 natural makes as little as 170 HP but can go 15,000 -20,000 hours between rebuilds, they work for displacement boats but it is really hard to build a boat capable of planing with a 2 ton motor putting out less than 200 HP.

They are simple to rebuild and following WW2, the knowledgeable base on how to work on them was really widespread but every year it diminishes and many younger mechanics just aren't interested in working on them. For a DIY'er they can still make a lot of sense. And they sound great, seem to raise fish like nothing else.

Running a 6-71T at 80% of 450 hp is still running it pretty hard. That is about 50 hp per liter. I recall Tony Athens saying that a diesel should be run at no more than 35 hp per liter for best life.

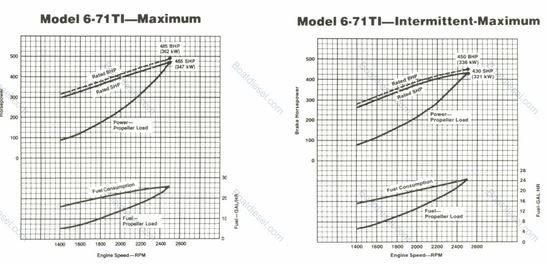

Also let me explain the performance curves given in post #3. The top curve is the engine shaft hp that can be produced at wot. It usually excludes alternator load and even raw water and coolant pump loads. The curve below that is the power at the prop shaft which subtracts the losses noted above and the transmission losses, again at wot.

The third from the top curve is the theoretical hp that a prop can absorb. It is based on the 2.5 exponent but some manufacturer's use the 3.0 exponent. This is a simplified estimate of what a prop will absorb and ignores things like "climbing over the hump" which will increase the hp required in that rpm range.

The fourth curve is the fuel consumption at wot.

The fifth or bottom curve is what you want to use to estimate fuel consumption at cruise on your boat. It takes the prop hp curve above and applies the fuel consumption measured by the manufacturer at each rpm and load, so it is partially theoretical (the prop load) and partially real world empirical (the fuel consumption at that rpm and load).

I have found that the prop fuel consumption curve is usually high but within 10% of reality on my boats except while climbing over the hump where it can be 25% off.

As I have said before pasting a copy of that curve on your dash is about as good as installing a Flowscan.

David

Also let me explain the performance curves given in post #3. The top curve is the engine shaft hp that can be produced at wot. It usually excludes alternator load and even raw water and coolant pump loads. The curve below that is the power at the prop shaft which subtracts the losses noted above and the transmission losses, again at wot.

The third from the top curve is the theoretical hp that a prop can absorb. It is based on the 2.5 exponent but some manufacturer's use the 3.0 exponent. This is a simplified estimate of what a prop will absorb and ignores things like "climbing over the hump" which will increase the hp required in that rpm range.

The fourth curve is the fuel consumption at wot.

The fifth or bottom curve is what you want to use to estimate fuel consumption at cruise on your boat. It takes the prop hp curve above and applies the fuel consumption measured by the manufacturer at each rpm and load, so it is partially theoretical (the prop load) and partially real world empirical (the fuel consumption at that rpm and load).

I have found that the prop fuel consumption curve is usually high but within 10% of reality on my boats except while climbing over the hump where it can be 25% off.

As I have said before pasting a copy of that curve on your dash is about as good as installing a Flowscan.

David

Bobupton

Member

- Joined

- Dec 22, 2021

- Messages

- 9

- Vessel Name

- Joyful Spirit

- Vessel Make

- 47 Mainship Motoryacht

Thank you very much, very helpfulDetroit Diesel got jealous of J&T and stopped selling them engines to make their own high HP engines. I don't remember when the changeover happened.

I use Shell Rotella T4 15w-40 I get at Walmart. My mains are 1947 engines that came with bypass filters. They've been overhauled once about 10 years ago. Most engines before 1950 used bypass filters and several still did in the 1950s. On later engines I always had a bypass filter besides the full flow filter until I went to using a centrifuge. I use the smallest micron spin on bypass filter or a hydraulic filter. Usually 1 or 2. You can't use a small micron in place of the full flow filter unless the engine oil system is very clean. And you better have an oil pressure alarm.

I get my filter elements usually from https://www.baldwinfilters.com

I buy by the case. Oil and fuel. Sometimes I buy on ebay. Almost any brand but Fram.

Even though I centrifuge my oil, I still run oil filters, they just don't get dirty. I batch clean the oil after a long run. Somewhere between 50-100 hours. My oil stays semi transparent. I test my oil yearly or about 500 hours. I take my oil sample before centrifuging. Otherwise it tests as new. The oil filters will catch some water and I always cut open spin on filters to see what was caught. There is a tool that makes cutting easy. They're about $40 on Amazon.

Because of the centrifuge, I haven't actually changed oil since 2011. It tests fine.

I try to run turbo engines at no more than 80% of total HP. In a sport fisher that means 25 instead of 30 knots. And a lot less fuel. I've owned several engines than never ran over 80% between overhauls. Turbos give much more power, but at the cost of metal wear. Boat builders like turbo engines because they can put a more powerful engine in a smaller space. Overhauling or replacing isn't their problem.

When to a Fleet supply yesterday and got my filters lube and fuel

Will go by Walmart and check out the Rotella T4. I had installed dual Racors (2040’s) on each engine. The boat was built by Luhrs in 1994-5 delivered early 1995. Only says DD on the front of the blower. I not sure but maybe DD did the conversations (671TI’s)

And I can fill the replacement filters by gravity feed, in changing the smaller Baldwin fuel filter (full flow ?) on the upper part of the engine will gravity fill the filter after I have start the spin on of the filter or do I need to pre fill it with fuel? Concerned about air lock. Tanks are pretty high on the 47 Mainship when full - 1/2 now.

The Lube filters - do I need to fill them with oil before replacing them or will that be taken care of when I crank the engine and retop off?

Last edited:

Bobupton

Member

- Joined

- Dec 22, 2021

- Messages

- 9

- Vessel Name

- Joyful Spirit

- Vessel Make

- 47 Mainship Motoryacht

Running a 6-71T at 80% of 450 hp is still running it pretty hard. That is about 50 hp per liter. I recall Tony Athens saying that a diesel should be run at no more than 35 hp per liter for best life.

Also let me explain the performance curves given in post #3. The top curve is the engine shaft hp that can be produced at wot. It usually excludes alternator load and even raw water and coolant pump loads. The curve below that is the power at the prop shaft which subtracts the losses noted above and the transmission losses, again at wot.

The third from the top curve is the theoretical hp that a prop can absorb. It is based on the 2.5 exponent but some manufacturer's use the 3.0 exponent. This is a simplified estimate of what a prop will absorb and ignores things like "climbing over the hump" which will increase the hp required in that rpm range.

The fourth curve is the fuel consumption at wot.

The fifth or bottom curve is what you want to use to estimate fuel consumption at cruise on your boat. It takes the prop hp curve above and applies the fuel consumption measured by the manufacturer at each rpm and load, so it is partially theoretical (the prop load) and partially real world empirical (the fuel consumption at that rpm and load).

I have found that the prop fuel consumption curve is usually high but within 10% of reality on my boats except while climbing over the hump where it can be 25% off.

As I have said before pasting a copy of that curve on your dash is about as good as installing a Flowscan.

David

Thank you helpful

Gdavid

Guru

As I have said before pasting a copy of that curve on your dash is about as good as installing a Flowscan.

David

I don't think this is accurate, the throttle lever for a diesel is not directly controlling the fueling, it is setting the governor speed, the governor then adjusts fueling to try and satisfy this setting. This is why diesels can be overloaded unwittingly. A flow scan or monitoring the exhaust gas temperature is needed to know the load.

This is not as critical on most displacement boats (or at least recreational) as long as they are propped correctly but a planning hull is more likely to end up overloaded due to dirty hull, dirty prop or loading too many crew, coolers, ice, fuel, etc which a sportfish boat is likely to experience.

I don't think this is accurate, the throttle lever for a diesel is not directly controlling the fueling, it is setting the governor speed, the governor then adjusts fueling to try and satisfy this setting. This is why diesels can be overloaded unwittingly. A flow scan or monitoring the exhaust gas temperature is needed to know the load.

This is not as critical on most displacement boats (or at least recreational) as long as they are propped correctly but a planning hull is more likely to end up overloaded due to dirty hull, dirty prop or loading too many crew, coolers, ice, fuel, etc which a sportfish boat is likely to experience.

I beg to differ. It doesn't matter if you have an rpm governed throttle or a direct fuel flow based throttle such as most trucks have. If the speed is steady and the same, the fuel flow will be the same no matter what controls the throttle.

The published fuel curve vs rpm is as accurate as the 2.5 power model that predicts hp required vs rpm and as I said above is usually within 10% of actual fuel burned measurements.

David

Gdavid

Guru

I beg to differ. It doesn't matter if you have an rpm governed throttle or a direct fuel flow based throttle such as most trucks have. If the speed is steady and the same, the fuel flow will be the same no matter what controls the throttle.

David

I respectfully remain disagreeable ( on this limited topic), if this were true, there would be no need for a governor at all. Perhaps the best example would be a generator, which maintains a consistent rpm but the consumption varies with load as the governor is adjusting the fueling.

Bobupton

Member

- Joined

- Dec 22, 2021

- Messages

- 9

- Vessel Name

- Joyful Spirit

- Vessel Make

- 47 Mainship Motoryacht

Any thoughts about filling the Oil Filters on these engines before the replacement filter on or will the engine fill the filter on a brief start and then top off the oil again ?

Additional thoughts on filling small fuel filter on the top of engine as I do on the dual Recors - Pretty sure I do but wanted thought that was needed to avoid air lock and possible could gravity feed

Additional thoughts on filling small fuel filter on the top of engine as I do on the dual Recors - Pretty sure I do but wanted thought that was needed to avoid air lock and possible could gravity feed

Gdavid

Guru

Any thoughts about filling the Oil Filters on these engines before the replacement filter on or will the engine fill the filter on a brief start and then top off the oil again ?

Additional thoughts on filling small fuel filter on the top of engine as I do on the dual Recors - Pretty sure I do but wanted thought that was needed to avoid air lock and possible could gravity feed

I would prefill both, Detroits are pretty good about self bleeding the fuel system but I wouldn't expect it to fill the secondary filter.

- Joined

- May 11, 2019

- Messages

- 3,688

- Location

- United States

- Vessel Name

- Muirgen

- Vessel Make

- 50' Beebe Passagemaker

On later engines I always had a bypass filter besides the full flow filter until I went to using a centrifuge.

Would you care to expand on the centrifuge you use? We're looking at going that route with our Gardner. It's not always easy to get rid of 22 quarts of used oil while cruising!

Lepke

Guru

- Joined

- Jun 19, 2016

- Messages

- 3,136

- Location

- US

- Vessel Name

- Charlie Harper

- Vessel Make

- Wheeler Shipyard 83'

I use a centrifuge made by these people:

WVO Centrifuge Systems - US Filtermaxx

If you go to their site there's lots of info on how it works.

Centrifuges are common on ships and large boats for cleaning fuel and oil. Where I first used them.

The oil enters a spinning drum and centrifugal force drives particles against the bowl sides where it is later removed. Depending on the flow rate it will remove particles below 1 micron. And it also removes water.

My boat has a waste oil tank and a pump and plumbing system that allows me to drain the engines into the tank after a run. It has a heater, but not necessary. Hot oil cleans better. The tank drains into the centrifuge. A metering valve on the centrifuge top sets the flow rate. As the oil flows thru, clean oil drains from the bottom to a clean tank. I transfer oil back to the engines in a 1gl oil container. I thought about return plumbing but haven't yet. The cleaning process takes about 30 minutes for about 15 gallons. When you clean, there's about a cup of dirt.

The last oil change was break in oil after a rebuild in 2011. Depending on use, I add about a quart to a gallon of new oil per Detroit in a year. Yearly oil tests. Each motor has a pet cock on the oil gallery so I can sample running. The sample is taken before the centrifuging. Afterwards, it would test better than new. After a few cleanings, all the residual dirt is out of the engine and my oil stays semi-transparent for about 50 hours. I do all my oil at once. For a few years I did separate batches and separate tests, but there was little difference. I replace the oil filters yearly, cut them open, and look at what they caught.

I'd say in 10 years, the centrifuge easily paid for itself in oil savings. I think I paid about $1000.

If you don't like that much work, put a good bypass filter on your engines. My experience before I went to centrifuging is it doubles engine life.

WVO Centrifuge Systems - US Filtermaxx

If you go to their site there's lots of info on how it works.

Centrifuges are common on ships and large boats for cleaning fuel and oil. Where I first used them.

The oil enters a spinning drum and centrifugal force drives particles against the bowl sides where it is later removed. Depending on the flow rate it will remove particles below 1 micron. And it also removes water.

My boat has a waste oil tank and a pump and plumbing system that allows me to drain the engines into the tank after a run. It has a heater, but not necessary. Hot oil cleans better. The tank drains into the centrifuge. A metering valve on the centrifuge top sets the flow rate. As the oil flows thru, clean oil drains from the bottom to a clean tank. I transfer oil back to the engines in a 1gl oil container. I thought about return plumbing but haven't yet. The cleaning process takes about 30 minutes for about 15 gallons. When you clean, there's about a cup of dirt.

The last oil change was break in oil after a rebuild in 2011. Depending on use, I add about a quart to a gallon of new oil per Detroit in a year. Yearly oil tests. Each motor has a pet cock on the oil gallery so I can sample running. The sample is taken before the centrifuging. Afterwards, it would test better than new. After a few cleanings, all the residual dirt is out of the engine and my oil stays semi-transparent for about 50 hours. I do all my oil at once. For a few years I did separate batches and separate tests, but there was little difference. I replace the oil filters yearly, cut them open, and look at what they caught.

I'd say in 10 years, the centrifuge easily paid for itself in oil savings. I think I paid about $1000.

If you don't like that much work, put a good bypass filter on your engines. My experience before I went to centrifuging is it doubles engine life.

Attachments

twistedtree

Guru

I respectfully remain disagreeable ( on this limited topic), if this were true, there would be no need for a governor at all. Perhaps the best example would be a generator, which maintains a consistent rpm but the consumption varies with load as the governor is adjusting the fueling.

In a boat the load only varies with sea state, and even then, the consequence is a lower speed. Bottom line is that at any given RPM, a prop load is constant, so the fuel rate, governor or not, is the same.

Gdavid

Guru

In a boat the load only varies with sea state, and even then, the consequence is a lower speed. Bottom line is that at any given RPM, a prop load is constant, so the fuel rate, governor or not, is the same.

The OP has a planing boat, the load and sea state has a much larger impact on a planning boat, or more specifically, a boat that should be capable of planning. Something as simple as trim fore and aft makes a huge difference in load on a planning boat.

I am afraid that I am coming off as argumentative, not my intention but I have a lot of experience running the subject motor on offshore sportfish

Last edited:

twistedtree

Guru

The OP has a planing boat, the load and sea state has a much larger impact on a planning boat, or more specifically, a boat that should be capable of planning. Something as simple as trim fore and aft makes a huge difference in load on a planning boat.

I am afraid that I am coming off as argumentative, not my intention but I have a lot of experience running the subject motor on offshore sportfish

Sorry, thread confusion on my part. There is another similar discussion re a Cat 3308 in a displacement boat. I agree with you about variable load on a planing boat.

Gdavid

Guru

Just had a quick thought - our 1995 47 Mainship Flagship

Has no operation Manual - would anyone have the Operator Manual

Be happy to receive a copy if someone has a digital copy.

Bob

You may get more response from the "Mainship Owner's Group" on Facebook. There seem to be more ower's of the late 80's and 90's vintage Mainships among that group compared to the 70's, early 80's, late 90's through 2000's which are better represented in this site.

- Joined

- May 11, 2019

- Messages

- 3,688

- Location

- United States

- Vessel Name

- Muirgen

- Vessel Make

- 50' Beebe Passagemaker

I use a centrifuge made by these people:

WVO Centrifuge Systems - US Filtermaxx

If you go to their site there's lots of info on how it works.

Good info, but even the smallest unit they have is WAY larger, in both capacity, and physical size, than I'd ever need! Also, no 120v motors offered, or I'd immediately have to replace the offered motor with another one. Thanks for the info, but I need to keep looking! There's one out there for me somewhere . . .

Speedcat

Member

Running a 6-71T at 80% of 450 hp is still running it pretty hard. That is about 50 hp per liter. I recall Tony Athens saying that a diesel should be run at no more than 35 hp per liter for best life.

Also let me explain the performance curves given in post #3. The top curve is the engine shaft hp that can be produced at wot. It usually excludes alternator load and even raw water and coolant pump loads. The curve below that is the power at the prop shaft which subtracts the losses noted above and the transmission losses, again at wot.

The third from the top curve is the theoretical hp that a prop can absorb. It is based on the 2.5 exponent but some manufacturer's use the 3.0 exponent. This is a simplified estimate of what a prop will absorb and ignores things like "climbing over the hump" which will increase the hp required in that rpm range.

The fourth curve is the fuel consumption at wot.

The fifth or bottom curve is what you want to use to estimate fuel consumption at cruise on your boat. It takes the prop hp curve above and applies the fuel consumption measured by the manufacturer at each rpm and load, so it is partially theoretical (the prop load) and partially real world empirical (the fuel consumption at that rpm and load).

I have found that the prop fuel consumption curve is usually high but within 10% of reality on my boats except while climbing over the hump where it can be 25% off.

As I have said before pasting a copy of that curve on your dash is about as good as installing a Flowscan.

David

This is excellent info, thank you! I'm wondering why the curve starts at 1400 RPM and doesn't include anything below that. I'd like to run two 671 TI engines at say, 1000 RPM or even lower, to get the most fuel economy at slow speed. Any thoughts on this and what that might look like for GPH? Thanks again

Lepke

Guru

- Joined

- Jun 19, 2016

- Messages

- 3,136

- Location

- US

- Vessel Name

- Charlie Harper

- Vessel Make

- Wheeler Shipyard 83'

No accurate idea. Best way is either install a flow meter or measure a tank you draw from.

I have a rectangular day tank and every inch is 5 gallons. So I run an hour, measure the tank and that's my answer.

If your tank is square or a rectangle: multiply LxHxW. 231 cubic inches = 1 gallon.

I have a rectangular day tank and every inch is 5 gallons. So I run an hour, measure the tank and that's my answer.

If your tank is square or a rectangle: multiply LxHxW. 231 cubic inches = 1 gallon.

Marco Flamingo

Guru

- Joined

- Jan 7, 2020

- Messages

- 1,198

- Location

- United States

- Vessel Name

- CHiTON

- Vessel Make

- Tung Hwa Clipper 30

I just looked around at the concept based on this thread. It seems that whether there is value in the concept depends on how much oil, and how often, one needs to change. For my little Lehman, I might save $50 a year. The payback would take more than my lifetime for some of the systems. But . . . here's one that is 12v and designed for recreational boat-sized applications.Good info, but even the smallest unit they have is WAY larger, in both capacity, and physical size, than I'd ever need! Also, no 120v motors offered, or I'd immediately have to replace the offered motor with another one. Thanks for the info, but I need to keep looking! There's one out there for me somewhere . . .

Similar threads

- Replies

- 17

- Views

- 1K

- Replies

- 8

- Views

- 518

- Replies

- 0

- Views

- 193

- Replies

- 2

- Views

- 512

Latest posts

-

-

-

-

-

-

-

-

Spectra water maker fresh water flush module valve position

- Latest: Portage_Bay

-

-