paulga

Guru

- Joined

- May 28, 2018

- Messages

- 1,316

- Location

- United States

- Vessel Name

- DD

- Vessel Make

- Marine Trader Sundeck 40'

I would also prefer a cap with hose , but my strainer does not seem to have threads

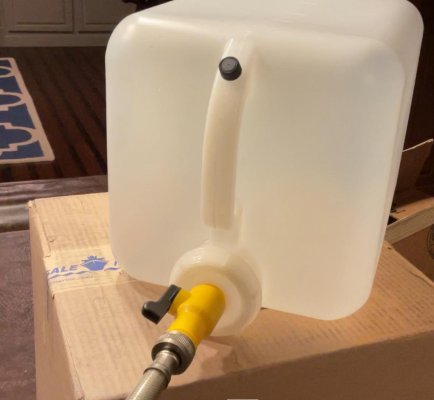

I had the room on a previous boat, and was able to just pour the antifreeze directly into the strainer for our gennie. I would imagine that the flow through the funnel would be sufficient for the generator. My HVAC’s lose prime and are not self priming so that is why I use the cap with the hose connection. Since I have it,I’m use it for the generator also.

For the engine, I would recommend the Seaflush. If you look it up on line, you will find videos showing how to use it.