Hi All,

I'm on a 60ft houseboat, with three decks, and a fully equipped kitchen on the top deck (so we are heavy, and top heavy). We're moored permanently in a typhoon shelter. We don't get big waves, but we get enough of a rock from wind and/or passing boats to make my wife seasick sometimes. As such, I'm looking to deploy some flopper stoppers. Unlike most, mine will be in the water permanently, so don't need to be packable or light. Our waves are also not huge. Extension arms are not an option, with boats parked on either side. Given our size, I think I may need to attach quite a few on both sides (I have 5 cleats on each side, so doable).

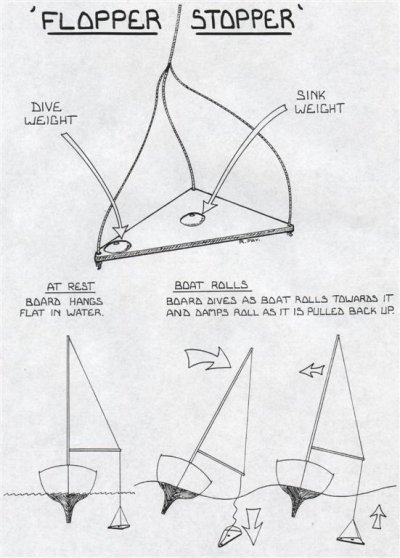

What do you guys suggest? I want something that is going to drop fast enough, which suggests flaps. I've considered Magma or FlopStopper. But given how many I probably need (and being based in HK) I'm thinking it might be much cheaper to do DIY. I've considered a DIY version like what was suggested by Simi 60 or the yellow one discussed by mvweebles.

However, given mine will be in the water permanently (and thus get barnacle growth) I'm thinking a lack of moving parts would make maintenance easier. Also, I don't care about weight. As such, I'm considering either just large steel disks on a chain, with extra chain below for weight. But that might not dive so well? The other idea is an upside down bowl (like the Australia-made round ones, but I'd probably do steel or aluminum) or upside down cone (pointy end down). I assume that making the item hyrdrodynamic downward, but purposely not so upward, would be better than a simple disk--correct?

Anyway, thoughts most welcome. Thanks all (from me and my seasick wife).

Will