To answer your original question, I would and did use one Racor 1000 filter separator. Below is a picture of my setup. A Racor 1000 is rated for 180 GPH.

What I would do differently next time would be 2 pumps. In essence, you want a fast pump for fuel transfer (3 GPM) and a slower (50 GPH) (bullet proof) pump to run continuously whenever the engine is running or you need to clean suspect fuel.

My choice for the second pump would be a plunger style, most likely Facet / Purolator. Basically they're a magnet coil pulling a plunger up against a spring with 2 simple check valves. They are incredibly reliable, often used in sub 12KW generators, and light sport aircraft. Part of the appeal of plunger style pump is simplicity and a failure of the mechanism can't cause a leak.

Regarding Procon pumps:

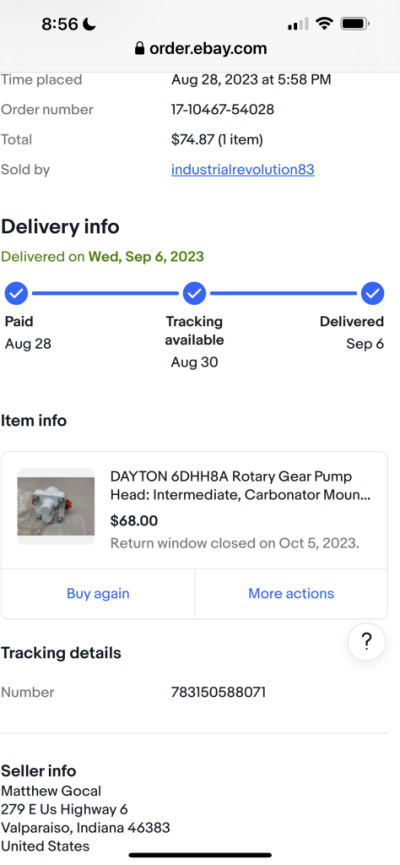

The below picture includes a Procon pump. That is my second one. The first one was covered under warranty by WW Grainger. The pump locked up and damaged the motor.

Ted